Thermal imaging is considered both a sophisticated and subjective method to measure temperature because it’s taking an “apparent” temperature. However, it can greatly assist in troubleshooting and process development. The purpose of this article is to show how it can supplement—not necessarily replace—other types of heat-sensing equipment and be less subjective.

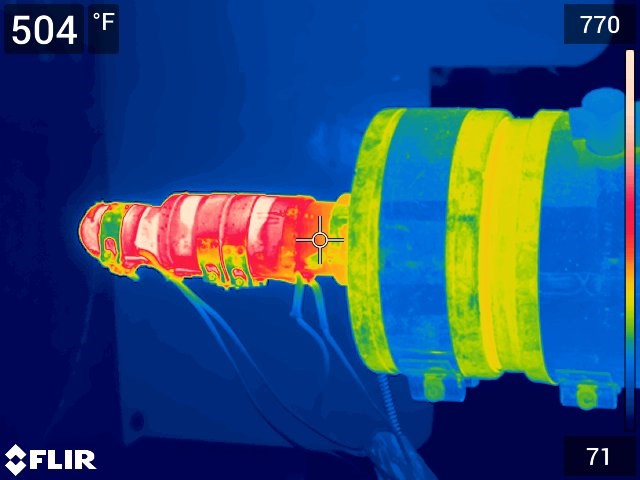

One of the biggest benefits to using thermal imaging is the speed at which a problem can be noted and quantified. When troubleshooting injection molding equipment, it is a quick way to find discrepancies in barrel heaters, water flows, dryers or mold heaters.

Higher-end thermal imaging cameras (TICs) can be pricey, but there are a lot of low- and mid-grade units that can be just as effective. Over the past few months, we at Juno Pacific, a molder that specializes in medical device manufacturing, have been trying to integrate TICs into our process-development and troubleshooting toolbox. To justify the investment, we took a known, calibrated, handheld pyrometer and compared its accuracy with that of the TIC before we purchased a higher-end camera. The following information is a compilation of the data we collected to justify the purchase and substantiate the idea that the device could be used on for troubleshooting and maintaining process stability.

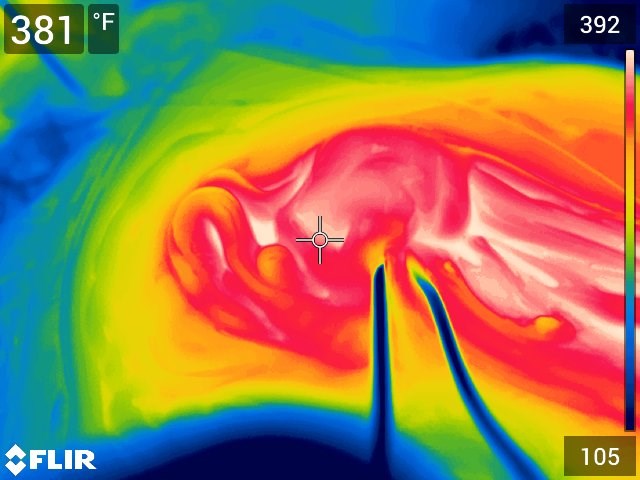

The first big obstacle that anyone must overcome in making this leap to thermal imaging is to bridge the gap between actual temperature and “apparent” temperature. Since infrared (IR) images are non-contact, they obviously take into account things like ambient temperature and other outside factors. However, as we quickly found, the data proves that there is little discrepancy between the apparent temperatures and contact-temperature measurements in an ambient environment. The speed at which IR images can be viewed and developed is where the real benefit lies.

So, if you’re trying to justify spending the money, you might ask questions like these:

• Can you validate this type of method (especially in a regulated industry)?

• Can you prove equivalency to current methods being used?

THE EXPERIMENT

When we were kicking the tires on the idea of using IR images for process development and troubleshooting, we had to answer the same questions. What we decided to do was put some different methods to the test side by side in our normal clean-room environment for comparison. We compared a calibrated, two-zone, handheld pyrometer; a calibrated, fast-response immersion probe; a calibrated, standard 0.125-in. diam. immersion probe; and a TIC.

Our methodology was as follows:

1. Take multiple purge samples on one machine.

2. Measure some of the samples with the fast-acting immersion probe (most used melt-temperature measurement method at our shop); not pre-heated.

3. Measure some of the samples with the standard 0.125-in. diam. immersion probe (one of the more readily available probes in our shop); not pre-heated.

4. Measure each sample with the IR camera.

5. Measure some samples using all three methods at the exact same time.

6. Measure and document time to equilibration

THE RESULTS

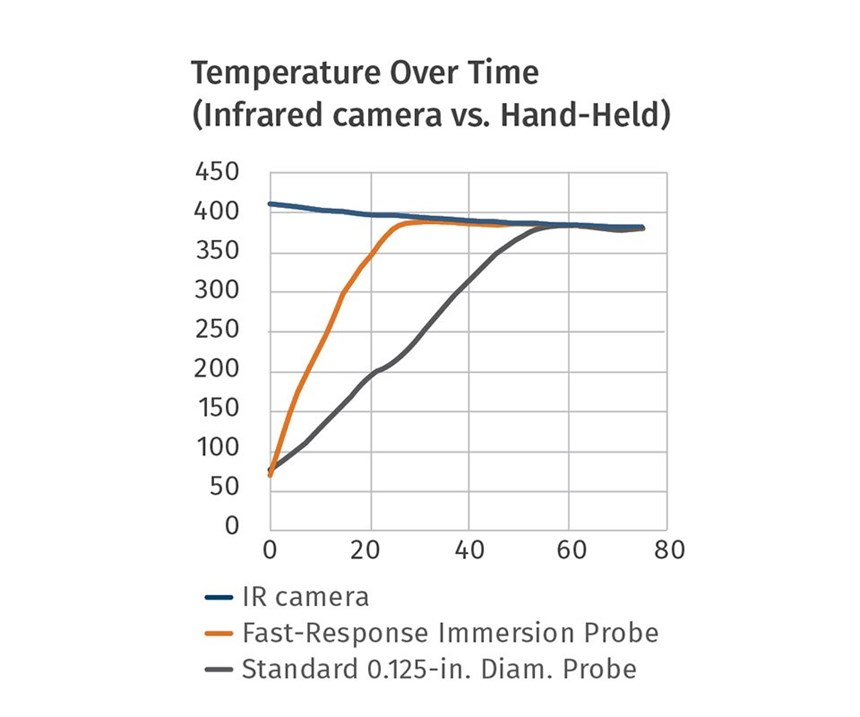

We immediately noticed that the temperature from the IR camera was within 2-4° F of the handheld measurements we were collecting. Furthermore, we noticed that the IR camera was by far the fastest; the fast-response immersion probe was the second fastest; and the thicker 0.125-in. probe was the slowest. What really got us scratching our heads was the amount of time that it took for all three methods to equilibrate.

The more shocking revelation was when we graphed the data for all three measurement methods, which highlighted how the IR camera was producing an accurate “right now” measurement of the melt.

The graph revealed that the IR camera generated an instantaneous measurement of temperature; the fast-responding probe took nearly 30 sec to equilibrate to the IR camera; and the other immersion probe took another 30 sec to equilibrate to the fast-response probe and camera. Using this data, we decided that it was well worth our time and money to purchase a camera to supplement our current methods of melt-temperature measurement and machine-performance analysis.

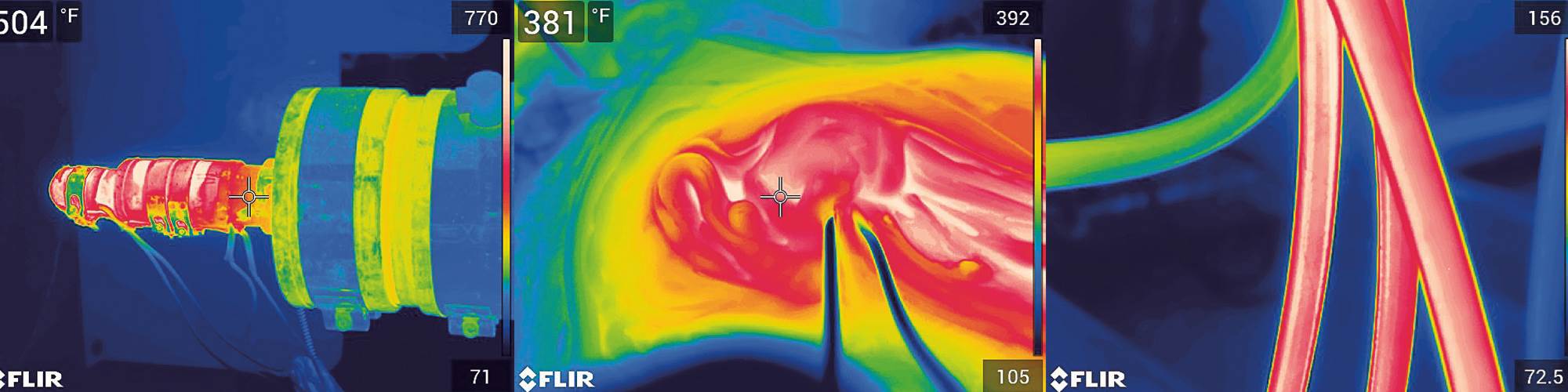

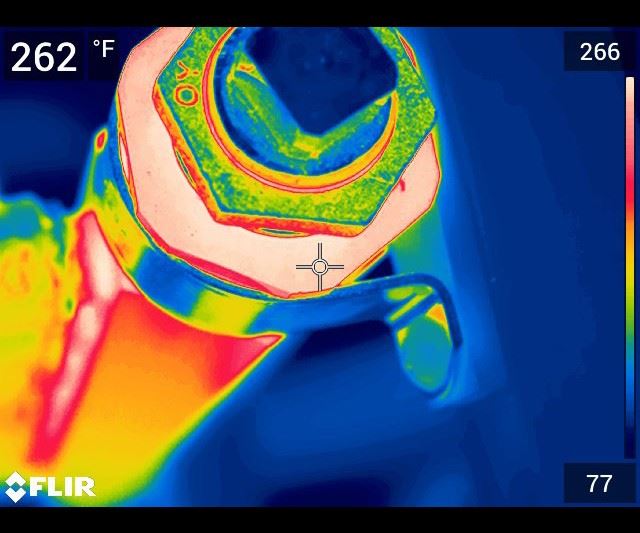

We have identified several machine problems aside from the experiment using the melt probes that normally would go unnoticed. For example, we had a nozzle-body heater that was running too hot, but the machine’s controller “read” that zone as being at the proper temperature because the heater was piggybacked to another zone that was not heating properly and it was compensating for the heat discrepancy.

LESSONS LEARNED

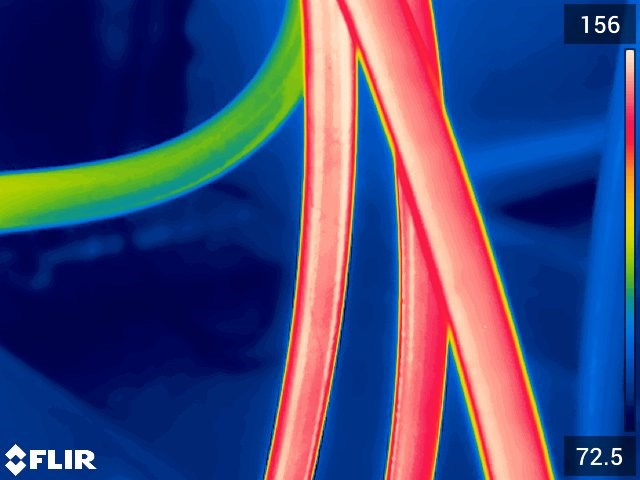

The camera does a number of tasks for us—from allowing our setup technicians to evaluate water flows, to detecting melt temperatures, to helping our building maintenance crew troubleshoot HVAC problems and diagnose electrical issues.

One of the biggest advantages of using an IR camera for process verification and troubleshooting is the non-contact aspect of getting data. Part ejection temperature, mold-water flow, and dryer operation can all be verified while the machine is running parts. Melt temperatures can be verified within seconds without the need for preheating probes. (Again, this is not necessarily a replacement, but a quick gut check of what’s going on. It’s a great supplement.) Even operators running or verifying the machine parameters can be trained easily to use the equipment.

If you have critical processes and want an easy way to troubleshoot, verify and maintain them, it cannot be overlooked how good this equipment has become. It also can’t be overlooked that the speed of the results and ease of use makes it easy for anyone to solve problems quickly.

Juno Pacific is a molder and not in the business of selling TICs, so this article is not intended as a sales pitch, but to simply make molders aware of the fact that there are faster, better ways of getting to root causes of problems. If you’re thinking about TICs, take the time to validate and verify that they are going to work the way you want them to. Consider multiple brands and models. Test them and then decide what works best for your environment. It doesn’t have to be too complicated to produce convincing results that spending the money will be worth it in the long run.

Related Content

Injection Blow Molder Reduces Maintenance, Power Consumption

Amcor applied Cito’s PulseCooling to reduce leaks and power consumption on its production floor while boosting output and accuracy.

Read MoreICYMI: August Roundup

A birthday, disc golf and a stolen tree all feature in the top articles from August that you might have missed.

Read MoreReifenhäuser Rolls Out Water-Cooled Blown-Film Line

Aimed at barrier applications requiring more puncture resistance, transparency or thermoformability.

Read MoreIndustry Vet Duff Joins ACS Group

With 37 years of experience on both machinery and processor side, Michael Duff to handle aftermarket business for auxiliary equipment manufacturer.

Read MoreRead Next

Beyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More