What’s With All the Static?

Static buildup on polymers can cause a variety of problems, some rather unpleasant. Yet there’s an inexpensive way to eliminate it, and we have data as proof.

If you have worked with plastic pellets for any length of time, you probably have had a significant physical experience with static electricity. Most of us have had a rude awakening and gotten zapped when we accidentally put our hand somewhere near a conveyor, pellets, or parts. If you have not had this experience, ask around, but be careful, as someone might just want to provide you a first-hand experience.

Conveying pellets and sometimes parts into dryers, machines, hoppers, conveying lines, or wherever, generates static electricity. If you provide the grounding link, it is moment you’ll remember. Static charge can be thousands of volts; enough to provide a spark, ignite a powder explosion, knock you down, and foul up your processing. How?

When flowing, some resins can develop a charge of static electricity, which will naturally look for a way to dissipate or go to ground. This static charge can (and does) foul processes by causing irregular feeding or separation of blends. Do you ever run a masterbatch of resin granules blended with a solid colorant? Next time you are walking through your shop take a close look at pellets in various hoppers. Often the colorant actually separates itself from the natural resin. The granules separate due the different charge between the natural and colored granules. It can be due to vibration, pellet size difference, or static charge. Granules may cling to the sides of the hopper, conveying tube, or discharge wand.

Ground wires are often attached to conveying equipment to prevent static buildup. The charge difference literally causes pellets to repel one another or migrate to the sidewalls of a container. Low humidity and dry pellets often exacerbate static buildup. With higher humidity or moisture, the water, which is polar, dissipates the charge. Just like in your home, you can build static electricity by walking on a rug when the humidity is low. Humidifiers add water to the air and minimize the static buildup.

Do not jump to conclusions here; I am not suggesting you add moisture to the granules. But wouldn’t it be nice if there were a surface coating or additive that would minimize or eliminate this static charge and not influence processing, physical properties, and part performance?

As it happens, there is just such a product. It has been tested with a number of resins and shown to eliminate static and not influence physical properties or part performance. Not only does it work well, but the amount needed is very small—only 100 ppm (0.010%). For 1000 lb of pellets, all you need is only 0.010 lb or 46 g. What is this magical fairy dust? It’s polyethylene glycol 400 molecular weight. As for cost, sit down for this: Amazon sells a gallon for about $100, and for significantly less in bulk.

Too good to be true? As an advocate of Scientific Molding, I believe that if you do not know the answer to that question, you must develop an experiment to provide data that tells you what you need to know and not guess at it. Therefore, I consulted Robert Pierce, a former colleague of mine in technical service for Dow Plastics in the late 1980s to early 1990s.

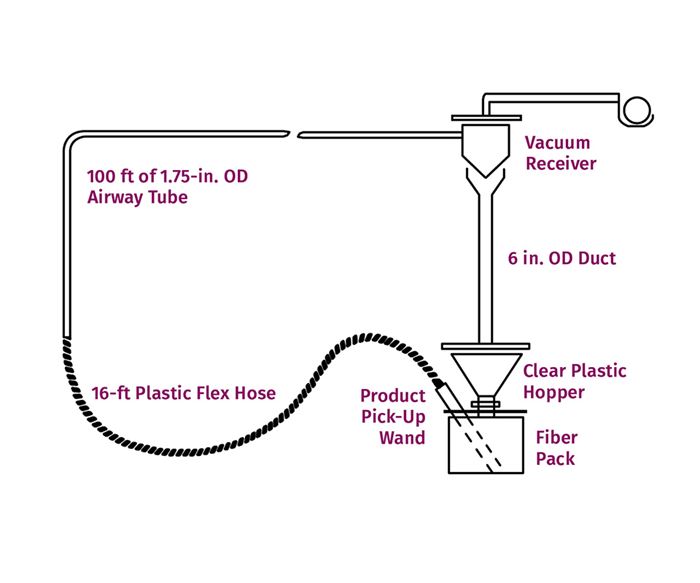

Bob made up sample blends of high-gloss ABS and transparent ABS with several different color concentrates. The samples were dried in a desiccant dryer for 3 hr at 180 F. Each sample was then loaded into an airway loop and conveyed continuously around the loop. At the end of the airway loop, the material dropped from a vacuum receiver through a clear plastic surge hopper and then into a fiber pack. A vacuum wand in the fiber pack would again pick up the material and send it back through the airway loop (see diagram).

After a few minutes of operation, Bob noticed that a significant static charge developed. A large quantity of color and some resin would build up on the clear plastic surge hopper. At this point, he slowly added a measured amount (100 ppm) of polyethylene glycol 400 MW to the blend. In each case, there was an immediate elimination of the static and the granules stopped clinging to the surge hopper. Continued running of the equipment showed no recurrence of the static buildup on resin or color pellets.

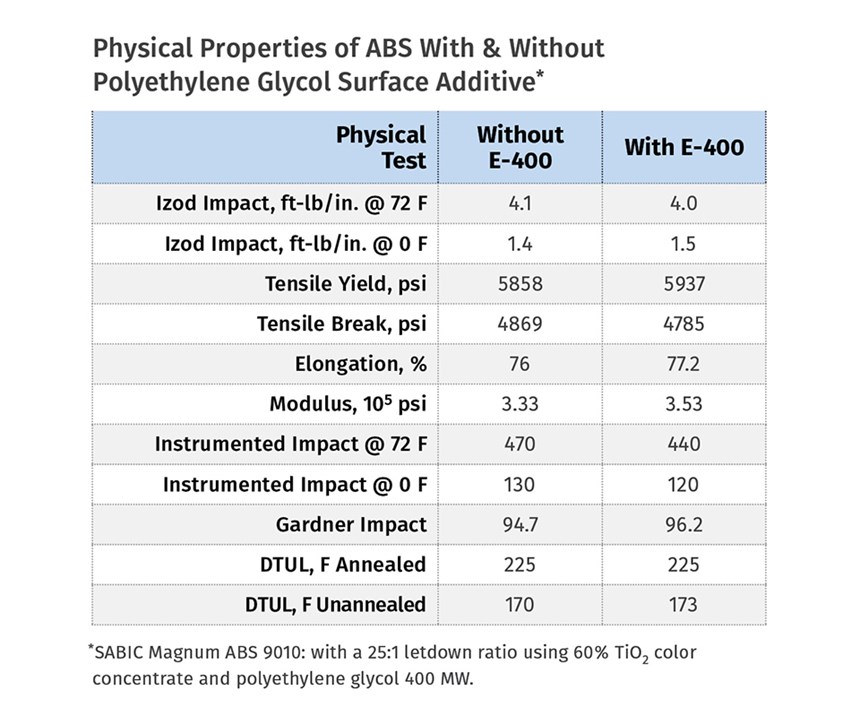

Samples of the resin and color were molded into ASTM test specimens and a tested for physical properties. The table presents data compiled by Bob Pierce that was typical of all samples. The data speaks for itself: There is no significant difference between the ABS with or without this surface additive.

Bottom line: Polyethylene glycol 400 (do not use a lower molecular weight) eliminates static on plastic granules without diminishing physical properties or part performance. Cost is minimal; it is highly effective and is readily available.

ABOUT THE AUTHOR: John Bozzelli is the founder of Injection Molding Solutions (Scientific Molding) in Midland, Mich., a provider of training and consulting services to injection molders, including LIMS, and other specialties. Contact john@scientificmolding.com; scientificmolding.com.

Related Content

Resins & Additives for Sustainability in Vehicles, Electronics, Packaging & Medical

Material suppliers have been stepping up with resins and additives for the ‘circular economy,’ ranging from mechanically or chemically recycled to biobased content.

Read MoreBASF to Purchase Pyrolysis Oil Produced From Waste Plastics

Agreement with Arcus Greencycling GMBH anticipates a volume of 100,000 ton/yr.

Read MoreGraphene Masterbatches for Flexible and Rigid Polyolefin Packaging and Beyond

Brazilian start-up Gerdau Graphene joins a growing group of graphene additives suppliers with a focus on boosting properties of large volume commodity thermoplastics.

Read MorePFAS-Free Processing Aid for Blown Film Extrusion

Ampacet’s new processing aid said to perform as well as fluoro-based PPAs in blown film.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read More

.jpg;width=70;height=70;mode=crop)