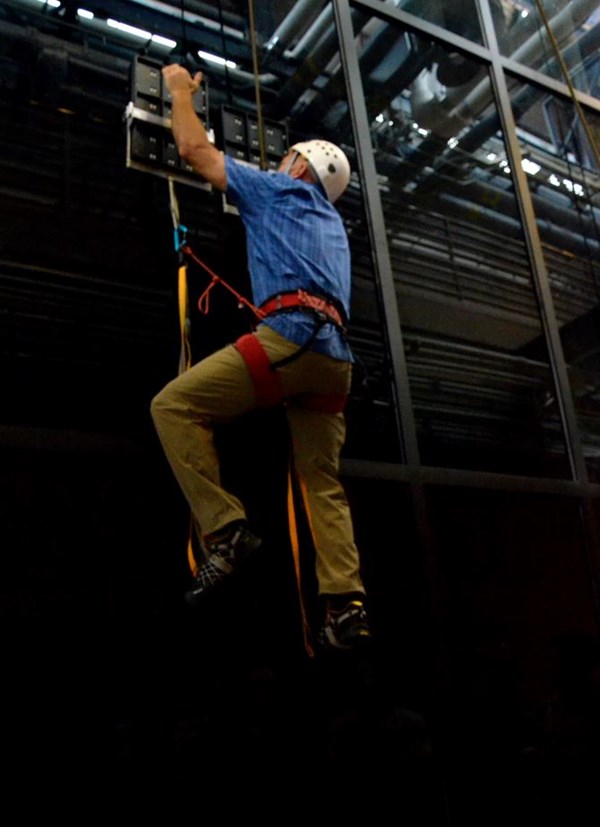

Climbing like a gecko thanks to molded silicone pads

The science of bio-mimicry seeks inspiration for new technologies in nature, and it’s hard to find a better natural climber than the gecko.

The gecko’s unique feet, which can scale smooth, vertical surfaces without surface tension, attracted the Defense Advanced Research Projects Agency’s (DARPA) Z-Man program, which seeks to give U.S. soldiers “maximum flexibility for maneuvering and responding to circumstances.”

A “novel polymer microstructure technology” was developed for DARPA by the Draper Laboratory of Cambridge, Mass., and built into paddles that allowed a 218-lb man, carrying a 50-lb pack, to go up and then down a 25-ft sheer glass wall, “with no climbing equipment other than a pair of hand-held, gecko-inspired paddles.”

In a paper published in the Journal of the Royal Society, the Draper scientists describe their advance as a “wedge-shaped gecko-like synthetic adhesive that exhibits several gecko-like properties simultaneously.” These include:

- Zero force at detachment

- High ratio of detachment force to preload force

- Non-adhesive default state

- Ability to maintain performance while sliding, even after thousands of cycles

“Individual wedges independently detach and reattach during sliding, resulting in high levels of shear and normal adhesion during drag,” the paper notes. They keep the stickiness too, retaining 67% of the initial adhesion and 76% of initial shear after 30,000 “attachment/detachment cycles” without cleaning.

The gecko-like pads were molded from a silicone, polydimethylsiloxane, using an epoxy (SU-8 photoresist) mold in a lithography process.

After the molds were created, silicone-based elastomers were cast under vacuum, spun to a desired backing layer thickness, heat cured and pulled out of the mold by hand.

Not exactly automated, and not a production tool by any stretch. The researchers noted that the molds typically lasted for only 10 “cast-and-peel” cycles before “cracking”, “delaminating” or “clogging” due to residual polymers left in the cavities. Time for some P-20 tool steel and a mold-release agent, perhaps?

Related Content

-

Melt Flow Rate Testing–Part 1

Though often criticized, MFR is a very good gauge of the relative average molecular weight of the polymer. Since molecular weight (MW) is the driving force behind performance in polymers, it turns out to be a very useful number.

-

Resin Prices Still Dropping

This downward trajectory is expected to continue, primarily due to slowed demand, lower feedstock costs and adequate-to-ample supplies.

-

The Effects of Temperature

The polymers we work with follow the same principles as the body: the hotter the environment becomes, the less performance we can expect.