Coping with Coronavirus: What If You Can’t Get a Tech Service Visit?

‘Social distancing’ for service technicians? Online remote servicing to the rescue!

Among the blizzard of emails I have received in recent days from businesses of all sorts telling me how they are dealing with the coronavirus pandemic, I received this one Monday, from Bob Cavanaugh, president of Engineered Printing Solutions (EPS), a maker of industrial inkjet and pad printers in East Dorset, Vt.:

“EPS will be restricting air travel by its sales engineers for the next 30 to 45 days. EPS technical service specialists will be allowed to travel to customer locations that will require new machine installations and emergency support services. For non-emergency support services, EPS will address on a case-by-case basis.”

Sounds like a sensible policy for the times, but it’s enough to make you think about the tech-service function industry-wide in the “new abnormal.” What if you are more than reasonable driving distance away from your machine vendor? What if—I hate to mention it—your vendor’s service staff is pinched by absences for illness or self-quarantine?

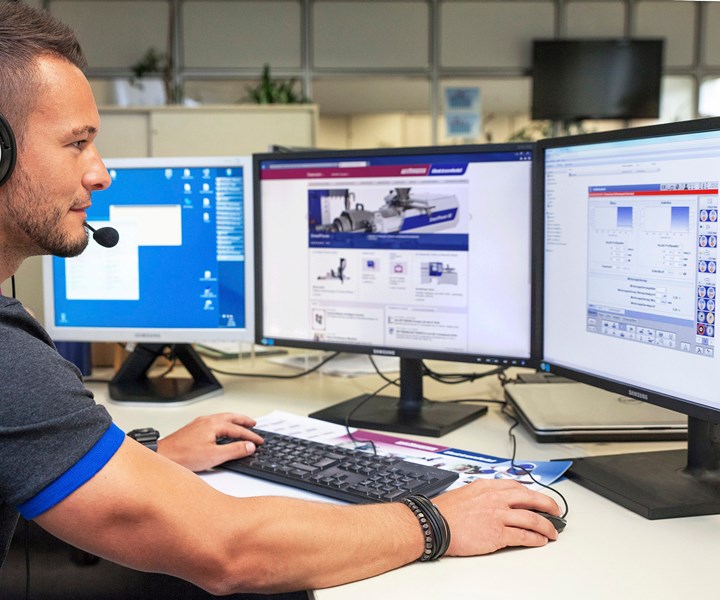

Many late-model machines allow service technicians to access the controls remotely at any time of day or night, without having to travel to the customer’s plant. (Photo: Wittmann Battenfeld)

You may already have an answer in the control systems on your production machines. Many builders of injection molding presses, and some makers of blow molding machines, have incorporated remote online servicing capability into their controls on their recent models. Some of them advertise this feature as part of the “Smart Service” element of their Industry 4.0 “Smart Factory” programs.

What remote-service capability offers is the ability for a technician located anywhere in the world to access directly your machine’s control system via the internet, so the technician can see just what you’re seeing on the screen display, and can get in there and perform diagnostics and even make changes in machine settings—all just as if he or she were in your plant.

You’ll find first-hand testimony of the value of remote servicing in the April issue of Plastics Technology. I wrote a Processors Edge story on custom injection molder T&M Enterprises in Shaftsbury, Vt. It’s a small firm with 15 presses, but it has up-to-date Wittmann Battenfeld machines with B6 and B8 controls that allow Wittmann technicians to access the controls remotely. “If we have a problem, they can look into the controls and see what the machine is doing and diagnose issues,” says T.R. Paquin, operations manager. “It’s a very useful and time-saving technology, instead of a lot of back and forth on the phone or having them send a guy out to visit us.”

No face mask or hand sanitizer required.

Related Content

-

How to Get Rid of Bubbles in Injection Molding

First find out if they are the result of trapped gas or a vacuum void. Then follow these steps to get rid of them.

-

Know Your Options in Injection Machine Nozzles

Improvements in nozzle design in recent years overcome some of the limitations of previous filter, mixing, and shut-off nozzles.

-

How to Select the Right Tool Steel for Mold Cavities

With cavity steel or alloy selection there are many variables that can dictate the best option.