Lots to Say About Recycling

In our July issue, we have two features with a recycling bent. We also have a new editor on board to track and report on future developments in this critical industry segment.

Photo: Starlinger

Last month I wrote about sustainability. I went on a bit about when I first heard the word as it related to our business. I indicated how I thought it would be just another flavor of the month—a passing trend—only to be proven wrong.

Here, I want to talk about recycling, which is one of several paths toward achieving sustainability in plastics processing. In our July issue, which will post here July 1 (print subscribers should get their copy in the mail soon thereafter) we’ve devoted two feature stories to the topic. One is our monthly On-Site, what we call our plant tour stories that detail the capability of a processor’s operation. Another feature this month is a comprehensive report on compatibilizers, which are additives that are increasingly being used in recycling applications to make dissimilar materials “play nice” with each other when they are mixed and melted in compounding machines.

Our coverage of recycling will continue in the months ahead. In September, as part of our pre-show coverage of K 2022 (Oct. 19-26 in Düsseldorf), we report on new technologies in materials and machinery that will continue to push recycling into the mainstream of our industry. The K 2022 fair, in fact, has designated the “circular economy” as one of its big show themes, noting on its website that “no other task has occupied the industry in recent years as much as the development of a functioning circular economy for polymer materials. The vision: new types of materials with at least proportions of PCR—quality-guaranteed to rank on a par with primary goods, easy and safe to use for every processor.” In the September issue we will also be reporting on new developments in sorting technology, a crucial aspect of pushing mechanical recycling beyond its current limits.

And as you read this, we have welcomed to new addition to the Plastics Technology editorial team. His name is Matthew Stonecash, and he will lead our coverage of recycling. He’s got a great background, with a B.S. in mechanical engineering, an M.S. in biomedical engineering and an M.A. in professional writing.

When I got into the trade magazine business about 40 years ago, publications tended to hire people from the industries on which their magazine focused, and “trained them up” on writing. Then the business shifted toward hiring journalists and set them out to learn about the technologies on which they would be reporting. The Plastics Technology editorial staff falls into the latter category, but Matt Stonecash has a rare combination of engineering smarts and creative writing skills that we believe will serve him well reporting on recycling. He will be based out of our headquarters office in Cincinnati.

I’m encouraged by all the financial commitment major players have made to further chemical or so-called advanced recycling technologies.

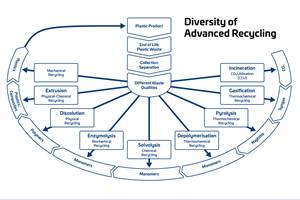

It will be interesting to watch developments in recycling unfold over the next five years. I’m encouraged by all the financial commitment major players have made to further chemical or so-called advanced recycling technologies. I think this technology has the potential to be a solution to the enormous challenges our industry has experienced, breathing new life into multilayer flexible packing, where structures typically consists of dissimilar materials sandwiched together to improve functionality. I’m also encouraged to hear about major processing companies getting into the recycling business as a means to lock in their supply sources.

I was very excited to attend the Recycling Conference in March and learn about major hauler and recycler Phoenix-based Republic Services Inc. move to establish the Republic Services Polymer Center, scheduled to open in 2023. This is reportedly the first time a U.S. company will manage the plastics stream through an integrated process from curbside collection of recycled material to production and delivery of high-quality recycled content for consumer packaging. I’m glad when I read about resin companies unveiling recycled-content materials, and machine builders in conveying and feeding—to name but two—introducing systems aimed specifically at handling reclaim.

There is, of course, an issue of supply. Let’s hope some of the big box retailers and online shopping providers, which have huge volumes of packaging materials running in and out of their establishments, get more involved in getting some of those materials back. That would be a huge help.

Related Content

Advanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read MoreInside the Florida Recycler Gearing Up to Take on Scrap at NPE2024

Hundreds of tons of demonstration products will be created at NPE2024 next spring. Commercial Plastics Recycling strives to recycle all of it.

Read MoreScaling Up Sustainable Solutions for Fiber Reinforced Composite Materials

Oak Ridge National Laboratory's Sustainable Manufacturing Technologies Group helps industrial partners tackle the sustainability challenges presented by fiber-reinforced composite materials.

Read MoreCompatibilizers Aid Recycling & Upcycling of Mixed Resins

Compatibilizers are proving their worth in boosting critical properties such as impact/stiffness balance of PCR and PIR blends of polyolefins and other plastics.

Read MoreRead Next

How Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreAdvanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read More