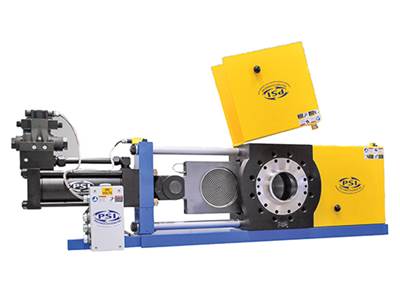

There are many good reasons for selecting a piston-type filtration system. First, such systems provide a large filtration area, which is not only cost-efficient, but also ensures a soft startup, lower shear rates, and lower differential pressure. This ensures good filtration because the lower forces prevent dirt particles from passing the filter element.

Another advantage of piston systems is the effective protection they provide against damage by foreign objects. There is enough room in the piston cavity so that metal contaminants, for example, cannot pass the screen barrier and cause damage during shifting movement of the screen bearing piston. Another advantage is that the continuous flow during normal operation prevents melt stagnation and polymer degradation. Unlike other filtration systems, piston-type screen changers do not have dead zones where material remains and degrades.

In a piston filtration system, every movement of the piston comes with a change in pressure.

Filtration systems are often designed for very specific processes. If the customer’s materials or their characteristics change, adaptations must be made to get the same good results. Parameters that work very well for one material can be a bad fit for another one. This also applies to pressure fluctuations. Constant pressure at the extrusion die or pelletizing system is one of the most important parameters in a polymer processing system. Only a uniform, constant polymer flow will result in uniform product.

In a piston filtration system, every movement of the piston comes with a change in pressure. Generally, this is not an issue and can be controlled in small ranges by the settings. But if these pressure fluctuations are too large, the product can be compromised by, for example, tears in film, thin spots in sheet, or pellets of irregular shape and size. In a well-adjusted system, where the piston movements for backflush and venting stops are set according to the process conditions, these fluctuations are kept to a minimum.

So, what can you do if pressure fluctuations occur nevertheless? Let’s examine some solutions looking at the key process variables:

Material: During troubleshooting it is always good to start at the beginning—in this case with the material. Is it lumpy, or damp? Lumpy materials are very hard to meter, so that uneven polymer flow already starts at the extruder. Damp materials not only tend to get lumpy, but also the residual moisture can have a viscosity-reducing effect.

Leakage: As a second step, perform a visual check of the equipment. Are there any obvious leakages? The processing line is usually a sealed system to keep the polymer flow nice and even. If material escapes the system through leakages, pressure fluctuations are likely.

Leakages can be caused by insufficiently tightened adapter bolts. Due to thermal expansion, you must retighten the screws after the screen changer is heated up to operating temperature.

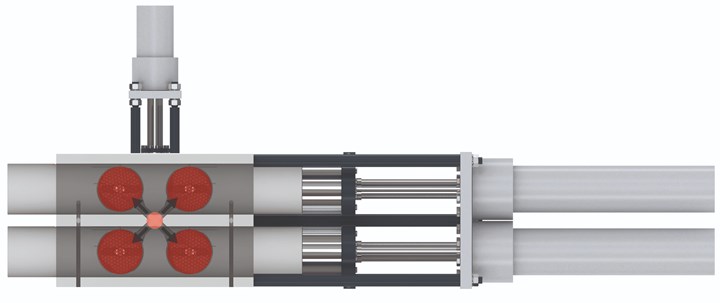

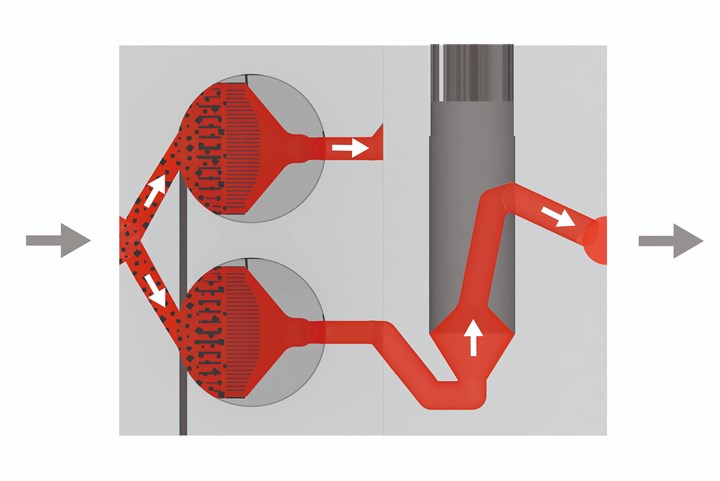

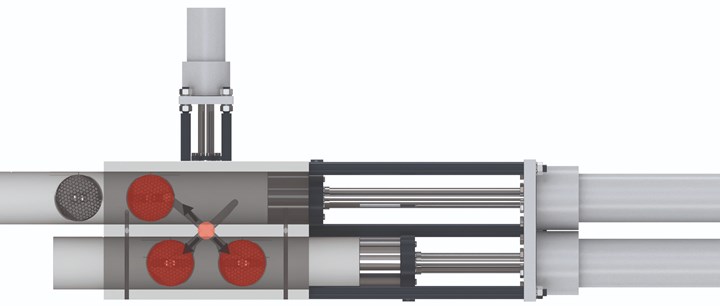

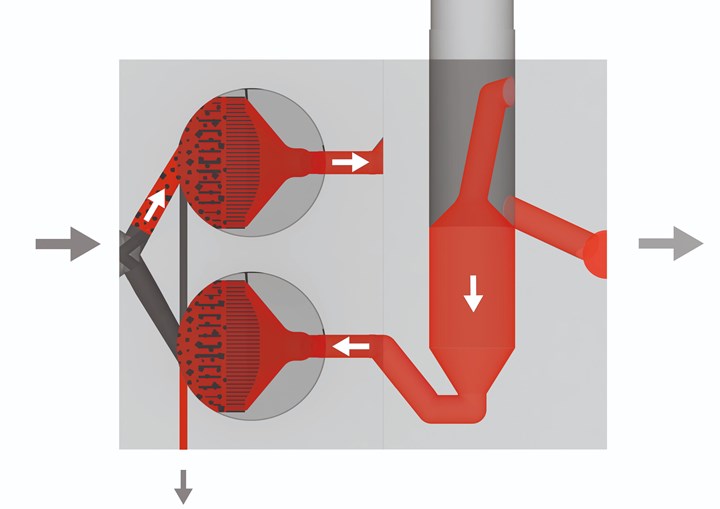

In normal operation, melt flow (shown in red) is subdivided into four paths, one through each of the four screen cavities.

In normal operation, melt flow paths are reunited after melt filtration. As contaminants are deposited on the screen packs, there is an increase in differential pressure, resulting in an increase in flow resistance.

On the other hand, screws that are too tight can be the problem. If the system is under too much tension, the alignment of the single components can be compromised, and leakages might develop.

Temperature: Check if the polymer process temperature is too high. This usually leads to a lower viscosity, for which the equipment and the sealing system might not be designed. Lowering the process temperature can solve this problem. In this context, it can also be beneficial to check the temperature sensors. If they don’t work properly the system can overheat, without your recognizing it. Low temperatures can also be the reason for pressure fluctuations. Check the surrounding conditions. Is there any draft that cools down the machine?

Sensor System: Make sure that the overall sensor system is working properly. A misplaced or badly calibrated pressure sensor can show pressure peaks where there aren’t any.

The Process: If the material is flawless, there are no detectable leakages, and the sensor system is working properly, you must dig deeper. For efficient troubleshooting, it is important to know when the problems occur during the process. The first question you should ask yourself is whether there have been any changes in the process. For example:

• Are you processing a different material?

• Have the operating temperatures increased?

• Are you experiencing troubles every time the piston moves?

• Do they come up during the screen change?

• Or does every backflushing procedure cause pressure drops in the system?

• Do the fluctuations become visible when the extruder or gear pump reaches maximum speed?

Always work closely with the operators. What observations have they made? If the system is equipped with a controller, check the pressure trends carefully. If there is no control system in place, almost every line has sensors to monitor the pressure. If the extruder or the pump increase their rotational speed in order to increase the material flow, then pressure is probably lost somewhere down the line.

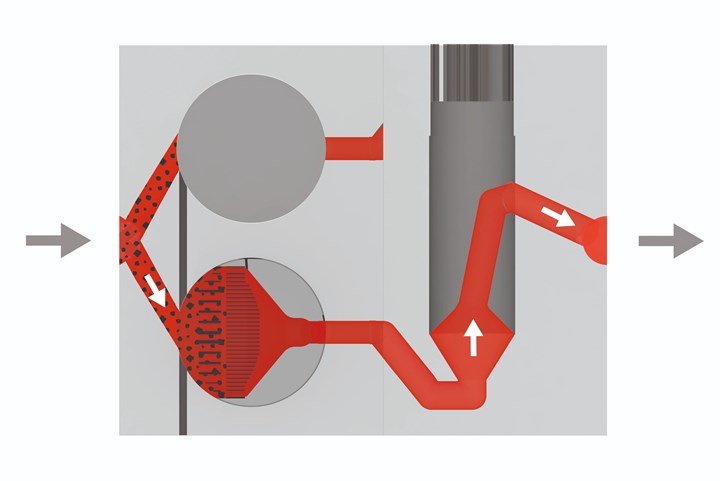

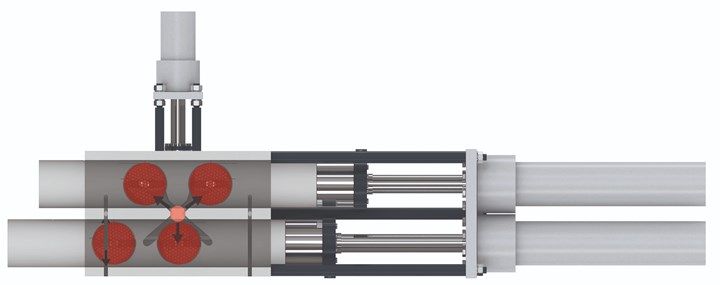

Screen Change: Every piston movement leads to a pressure change in the system. During a screen change, the piston moves out into screen-change position and shuts the cavity from the flow channel. The melt flows through the remaining cavity or cavities with an increased differential pressure. After filter change, the piston moves back into production position and the cavity is flooded with polymer in a so-called venting procedure. If this happens too fast and the cavity is filled too quickly, the melt pressure drops. Simply reducing the piston speed can solve that issue.

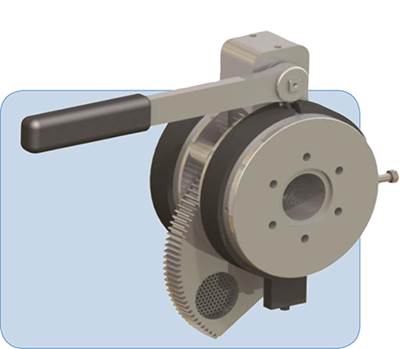

For screen change, the filter element to be cleaned is moved far enough out of the screen changer housing for the screen pack to be removed and replaced with a new one.

A sensitive filling of the filter cavity to prevent pressure fluctuations after screen exchange is especially important in processes where the extruder does not compensate for takeaway of material by increasing speed. This is also the case for very low-viscosity polymers.

Venting: When the cavity moves back into the flow channel after a screen change, it is important that no air is in there. If air bubbles get entrapped into the final product, they can cause holes and snap the line.

To avoid this, the pistons have venting grooves that allow air to escape during the filling process. Make sure that you clean these grooves properly after the screen change so there is enough space for the melt. The goal is that melt emerges from all venting grooves evenly and without any bubbles. Every material has its own perfect venting time and position and it takes some experience to find it.

Sensitive venting is very important when processing low-viscosity polymers.

Check whether the pressure is dropping at the first venting position. If this is the case, lower the piston speed so the cavity does not fill too quickly. The first venting position is the most important. If the timing is set right here, the other venting positions follow along and line performance can improve significantly.

Sensitive venting is very important when processing low-viscosity polymers. Pressure fluctuations are also a sign of turbulence within the cavity that needs to be filled. Turbulence caused by fast filling can result in so-called “champagne cream,” the distribution of small air bubbles in the cavity. This will lead to trouble in the final product. Therefore, it is always beneficial to adjust for smooth and sensitive filling, so that there remains a phase barrier between melt and air, which allows for a perfect venting effect.

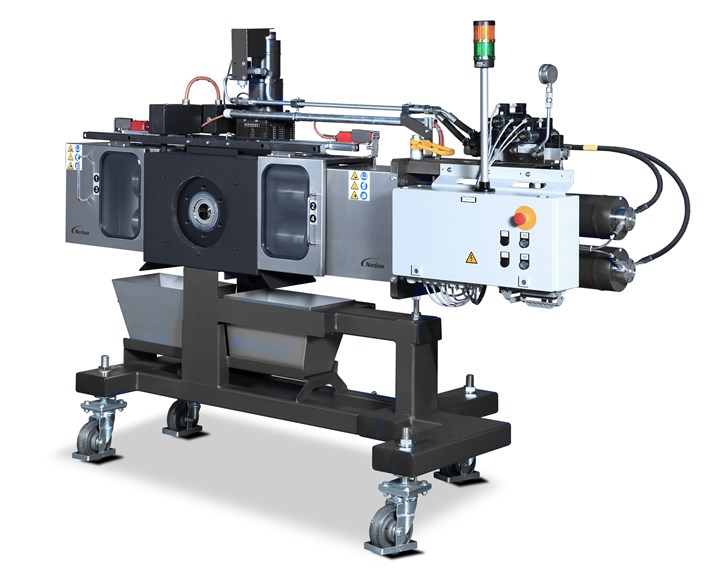

Taking time for a sensitive venting procedure saves money in comparison to a “quick and dirty” venting. State-of-the-art piston filtration systems provide an automatic venting function, where no action by the operator is needed.

Backflushing: In systems that clean away contaminant by means of backflushing, the melt flow is reversed and flows through the screen against the extrusion direction. The dirt particles loosen from the screen and are diverted out of the cavity through a backflush pipe. This increases the lifetime of the screens and the overall process stability.

But again, every backflush changes the pressure within the system, since material is withdrawn. The goal is to keep the material loss to a minimum without compromising the cleaning effect on the screens.

If the backflush procedure causes pressure peaks that are too high and therefore impact the end product, try to reduce the material loss by adjusting the piston parameters. It can be beneficial to shorten the backflush intervals a bit. If the screens are too clogged and a lot of melt pressure is needed to loosen the dirt particles, more material is lost.

The goal in backflushing is to keep the material loss to a minimum without compromising the cleaning effect on the screens.

A sensitive adjustment of backflush settings is especially important in the case of low-viscosity polymers or processes where the extruder does not compensate for a takeaway of material by increased extruder speed. It is always beneficial to adjust for a smooth and sensitive backflush, so that dirt particles can get out via the backflush boring at low velocity.

Screen pack: The screen pack is where the filtration happens. It is also the place where the most pressure gets lost. The melt flow must pass a barrier, so the pressures before and after the screen pack are different and result in a pressure differential. The finer the filtration level, the smaller the open area of the filter mesh or the higher the viscosity, the greater the corresponding pressure differential.

A screen pack with high-quality weaves and a symmetrical design, exactly fitted to the cavity, can help keep the differential pressure to a minimum and ensure a smooth process. The symmetrical design helps to even out the pressure differential before and after the screen. A high-quality screen and a good fit ensure the perfect distribution of the polymer over the filtration area.

ABOUT THE AUTHOR: Oliver Brandt has served the plastics industry for almost 20 years. He joined Kreyenborg (now part of Nordson Corp.’s Polymer Processing Systems business) in 2002, as a process engineer with a special focus on pump and filtration technology. In 2018, he took over the position of Marketing Development Manager for Recycling. Brandt holds a degree in Plastics Technology from the University of Paderborn, where he focused on extruder technology, polymer rheology, and plastic machinery design. Contact: 49-251-26501-595 oliver.brandt@nordson.com; nordson.com.

Related Content

How to Estimate and Control Head Pressure

You rightfully worry about melt temperature, but don’t overlook head pressure, because the two are closely linked and will influence line performance.

Read MoreThe Importance of Barrel Heat and Melt Temperature

Barrel temperature may impact melting in the case of very small extruders running very slowly. Otherwise, melting is mainly the result of shear heating of the polymer.

Read MoreUnderstanding the ‘Science’ of Color

And as with all sciences, there are fundamentals that must be considered to do color right. Here’s a helpful start.

Read MoreFormulating LLDPE/LDPE Blends For Abuse–Resistant Blown Film

A new study shows how the type and amount of LDPE in blends with LLDPE affect the processing and strength/toughness properties of blown film. Data are shown for both LDPE-rich and LLDPE-rich blends.

Read MoreRead Next

Get Smarter About Melt Filtration

As quality specifications become tighter and the need to use more recycled materials becomes more prominent, more and more extrusion processors are examining their options in melt-filtration technology. Here's some help in evaluating your options.

Read MoreFinding the Right Melt Filtration System for Post-Consumer Recycling

To achieve high-quality pellets at the end of the recycling process, chose filtration technology based on both the input materials as well as the performance requirements of the finished material.

Read MoreKeep Your Screen Changer In the Flow

The screen changer plays an essential role in generating quality extrudate. Here’s what you need to know to keep it functioning properly.

Read More