What is the right flow?

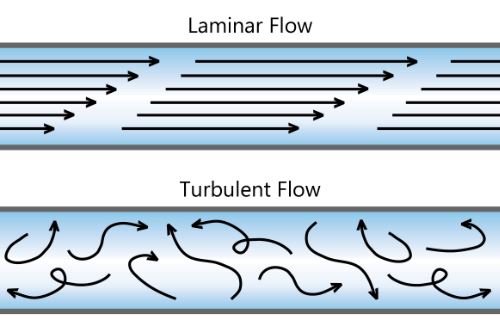

The process flow is equally - if not more - important than the temperature. The higher the flow, the more likely heat transfer will occur. There are two types of flow that can occur inside a pipe or heat exchanger: laminar and turbulent.

Laminar flow is slower and fluids pass along the walls of pipes in a parallel direction with very little to no mixing occurring. With this type of flow heat transfer is limited to only that fluid which is right next to the wall of the pipe or heat exchanger surface.

Turbulent flow occurs when the velocity of the fluid increases. The streams of fluid flow start to destabilize and more and more mixing occurs. In this case, fluid is warmed by the surface of the pipe or heat exchanger but then is mixed with the cooler fluid in the center of the pipe. This action pulls more heat off the side wall of the pipe or heat exchanger surface. The net effect is a significant increase in the amount of heat transfer to the process fluid.

What is the right cooling system?

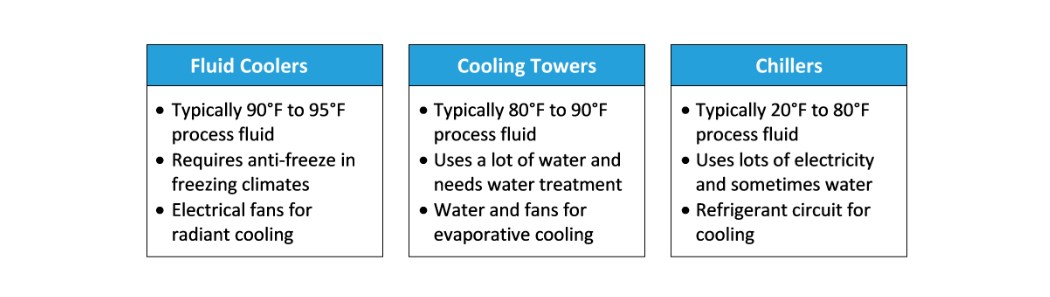

There are many types of cooling systems but in the end they all do the same thing, they remove the heat from the process and put it into the air. The three main types of cooling systems used in process cooling applications are: fluid coolers, cooling towers, and chillers.

Fluid coolers use fans to move air over a coil that has fins on it. Inside the coil is the process fluid. As the air passes over the fins it removes heat from the fluid. If the ambient air is not cool enough to achieve the temperatures needed in summer, an adiabatic pad is placed in the incoming air-stream that pre-cools the air before it passes over the coil. This type of system can typically produce process fluid temperature of 85°F in the summer.

Cooling towers use the principle of evaporation to cool fluids. Most cooling towers directly cool water by pumping it through a section of plastic sheets called fill. As the water passes over the fill sheets air is moved through the cooling tower which evaporates some water and cools the water that remains. Sometimes cooling towers isolate the process fluid from the fluid that is evaporated. These are called evaporative fluid coolers.

When the process fluid temperature must be cooler, a chiller is used. The chiller works on the principle of compressing and expanding a refrigerant gas. Essentially, it uses the heat from the process fluid to boil or evaporate the refrigerant. Air-cooled chillers use air, usually 95°F or cooler, to condense the refrigerant. Water-cooled chillers typically use 85°F or cooler water, oftentimes from a cooling tower system, to condense the refrigerant.