AMP Robotics Announces Milestones in Recycling Automation

A lack of data transparency, reliability, and consistency on the performance of material recovery has been a longstanding obstacle to recycling modernization.

AMP Robotics Corp. recently announced key company milestones, which coincide with the company’s ongoing market expansion and continued innovation cycle to modernize the domestic and global recycling system.

“We entered 2021 with momentum driven by strong demand for our recycling AI and automation solutions, and it continued through the first half of the year as we continued to deploy systems at scale and doubled year-over-year revenue,” said Matanya Horowitz, founder and CEO of AMP Robotics. “Our investment in operational scale is paying off as we see even stronger adoption of our technology, with customers re-ordering systems to install in other facilities that they own. We continue to innovate with the pilot of our automated secondary sortation facility, as well as the launch of AMP Clarity, our new waste characterization software. AI is powering real-world solutions for the recycling system that may have seemed out of reach not long ago.”

According to the company, lack of data transparency, reliability, and consistency on the performance of material recovery has been a longstanding obstacle to recycling modernization. Data is the foundation of the company’s AI platform, AMP Neuron, whose artificial neural network has created the reported largest known real-world dataset of recyclable materials for machine learning. With the power of this data, AMP has achieved two milestones:

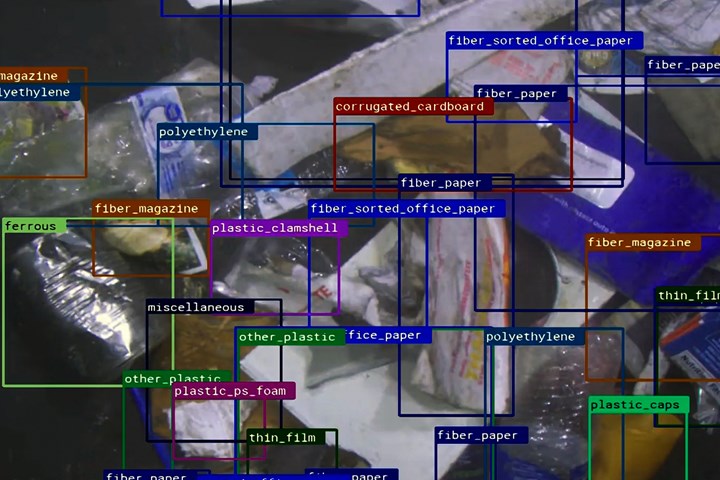

- The company can now classify more than 100 different categories and characteristics of recyclables across single-stream recycling, e-scrap, and construction and demolition debris.

- AMP has extended its object recognition run rate to more than 10 billion items annually. This combination of scalable accuracy and classification creates a step-level solution for data collection and measurement that materials recovery facilities can use to optimize their operations; reclaimers, mills, and manufacturers can use to validate that incoming feedstock meets specifications and standards for chemically compliant bales; and brand owners and government stakeholders can use to measure the quality, flow, and recovery of recyclable materials.

AMP’s proprietary AI technology applies computer vision and deep learning to guide high-speed robotics systems to precisely identify and differentiate recyclables found in the waste stream by color, size, shape, opacity, consumer brand, and more, storing data about each item it perceives.

Related Content

-

How Was K 2022 for Blow Molding?

Over a dozen companies emphasized sustainability with use of foam and recycle, lightweighting and energy savings, along with new capabilities in controls, automation and quick changeovers.

-

New Technology Enables ‘Smart Drying’ Based on Resin Moisture

The ‘DryerGenie’ marries drying technology and input moisture measurement with a goal to putting an end to drying based on time.

-

Cobot Creates 'Cell Manufacturing Dream' for Thermoformer

Kal Plastics deploys Universal Robot trimming cobot for a fraction of the cost and lead time of a CNC machine, cuts trimming time nearly in half and reduces late shipments to under 1% — all while improving employee safety and growth opportunities.