Edge-Bead Reduction Die for Coatings, Largest-Ever 'Nano' Feedblock

Edge-bead reduction (EBR) die allows frequent web width and formulation changes, while nanolayer feedblock produces stretch films with enhanced performance.

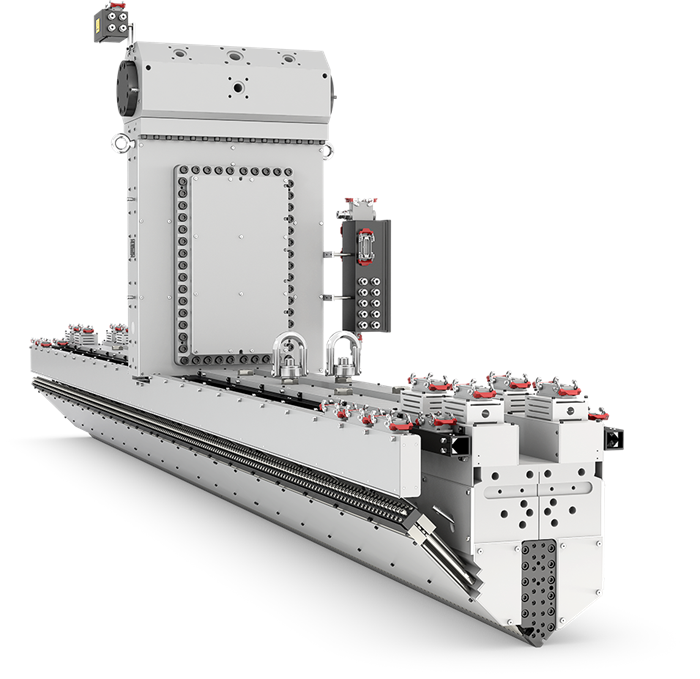

Cloeren Incorporated. is showcasing the EBR V (edge bead reduction) die for extrusion-coating applications for the first time. The EBR V is the latest and most advanced design in its EBR series. With an installed base of more than 50 EBR V dies over the past five years, the new design has reliably demonstrated increased operational robustness over any other edge bead reduction die in the market, Cloeren says.

EBR dies are a key technology for the extrusion coating and lamination processes. These applications require great flexibility, specifically frequent web width and formulation changes. Being able to reliably minimize the volume of material at the edge bead with the EBR V deckle system is an essential advantage with economical and environmental positives, according to Cloeren.

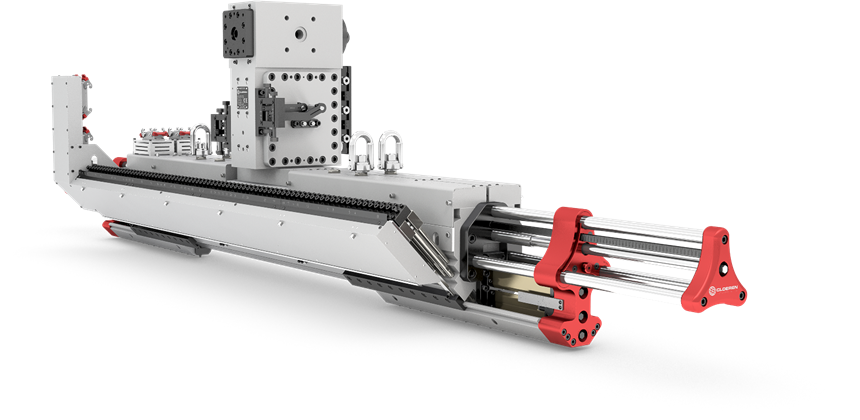

Cloeren is also displaying world’s widest NanoLayer system, comprised of a 55-layer NanoLayer feedblock, paired with a 5435-mm Epoch III die. This state-of-the-art system will be producing the third-generation (G3) of NanoLayer stretch films. NanoLayer films have become a mainstay in the cast stretch film industry for enhanced performance in high-speed power pre-stretch applications. Second-generation NanoLayer stretch films have provided measurable reductions in shipping losses through their enhanced performance over conventional stretch films, and G3 films have been developed for further enhancements in packaging integrity.

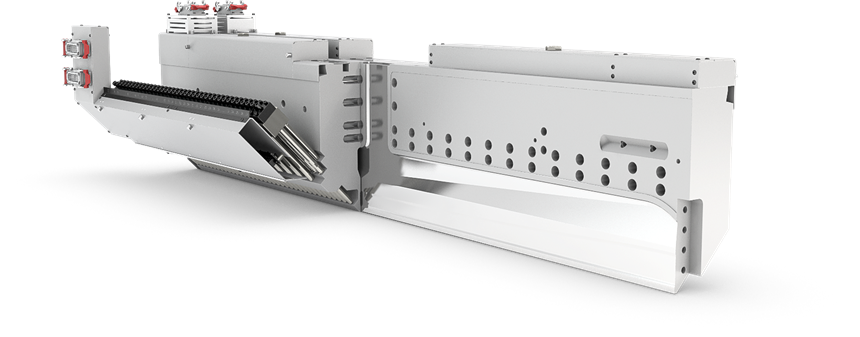

Cloeren’s patented moebius-manifold die is also on display. The innovative internal geometry of this die has proven to be particularly suited for processing residence-time-sensitive polymers, including PVC formulations.

Related Content

-

Die-Service Cart Upgraded to Handle Screws, Chill Rolls

Processing Technologies International LLC has released its next-generation flat die servicing system, the uCAMS (Universal Cleaning Assembly and Maintenance System) Plus.

-

Non-Contact Control of Flat Dies, Adapters

More automation comes to flat die technology.

-

Macro Names Anzini Tech Sales Manages for Southeast

Has worked in technical roles for leading processing companies in his career of 40+ years.