PP Compounds for Foam Injection Molding

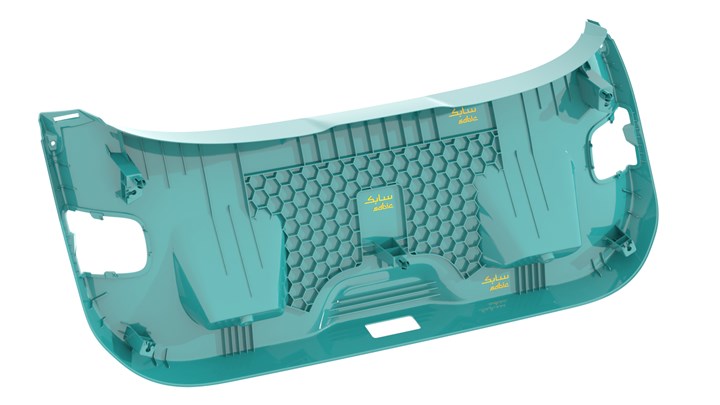

SABIC’s new mineral-reinforced PP compounds said to deliver excellent aesthetics for visible automotive interior parts with complex geometries.

Three new mineral-reinforced PP compounds from SABIC have been shown to deliver excellent aesthetics for visible automotive interior parts with complex geometries, such as door panels and trim, seat and trunk cladding, A/B/C/D pillar covers and center consoles. SABIC PPc F9005, PPc F9007 and PPc F9015 grades, unlike standard foam injection molding (FIM) materials which typically exhibit surface defects, reportedly feature uniformly high surface quality similar to solid injection molded parts. The new SABIC PP compounds have launched in Europe, with upcoming availability in the Americas and Asia/Pacific.

Compared to solid components, foamed parts made with SABIC PP compounds offer significant weight savings that can help cut emissions. According to a cradle-to-grave life cycle assessment study (pending third-party review), the advanced new materials can help OEMs lower carbon dioxide (CO2) emissions by as much as 15 %.

Previously, the FIM process was essentially limited to non-visible parts, restricting its usefulness in automotive applications. Foaming can underperform in surface aesthetics: silver streaking, swirl lines and dimples are common defects. The new SABIC PP compounds for foamed interior parts deliver low-gloss textured (grained) surfaces with uniformly high quality, including the elimination of streaking and swirling. Talc filler in these grades acts as a nucleator that promotes the generation of finer bubbles, which contribute to a consistent surface appearance. For enhanced aesthetics, these grades are currently available in selected automotive interior colors with custom coloring also available.

Weight reduction results with SABIC PP compounds depend on several factors, including the type of FIM technique used. Short-shot molding, which uses the same tooling as an injection molded part, can reduce weight by up to 10%. SABIC PPc 9007 is formulated for short-shot FIM and low-impact applications. Core-back molding, which requires part redesign and new tooling, can lower weight by as much as 30%. Both SABIC PPc 9005 and PPc 9015 grades are formulated for core-back molding and deliver medium stiffness and impact.

The choice between the short-shot and core-back techniques, with their different tooling requirements, also helps to determine whether FIM with SABIC PP compounds is cost neutral or delivers cost savings. Additional cost savings are possible from cycle time reductions from flow improvements inherent in FIM.

Another consideration is the foaming process, which can use chemical or physical agents. The new SABIC PP compounds are good candidates for use with chemical blowing agents, which are typically preferred for visible foamed parts. These agents are introduced to the molding machine in the form of a masterbatch, along with the plastic pellets, and activate during the melt phase to release gases for foaming.

SABIC fully supports its new PP compound portfolio with extensive expertise in foamed part design, development and processing, as well as predictive engineering capability. The company can provide guidance on the selection of the appropriate chemical blowing agent for each grade, and a SABIC team will collaborate with customers to achieve excellent aesthetics at the lowest possible part weight.

To drive future developments in polymer foams, SABIC operates a Foam Innovation Center in The Netherlands. This center, which is equipped with foam process capabilities as well as analytical equipment, enables the company to develop new foam solutions and technology innovations and collaborate with customers.

Related Content

The Fundamentals of Polyethylene – Part 2: Density and Molecular Weight

PE properties can be adjusted either by changing the molecular weight or by altering the density. While this increases the possible combinations of properties, it also requires that the specification for the material be precise.

Read MorePrices Drop for All Five Commodity Resins

While PE price reductions were not as apparent, they too were following the year-end price trajectory of PP, PS, PVC and PET.

Read MoreFundamentals of Polyethylene – Part 3: Field Failures

Polyethylene parts can fail when an inappropriate density is selected. Let’s look at some examples and examine what happened and why.

Read MoreA New Beginning for Polymers Without Ends

Oboro Labs aims to scale production of cyclic polymers.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More