EXTRUSION: System Precisely Meters Blowing Agents

Blowing agents pumped in quantities proportional to extruder speed.

The Ecofoam system from Lewa GmbH, Leonberg, Germany, consists of a pump that combines with measurement and control technology to reportedly offer precise feeding of blowing agents while minimizing downtimes. The system pumps blowing agent such as CO2, propane, butane, halogenated hydrocarbon and pentane in quantities proportional to extruder speed to reportedly provide precise metering even when pressures are fluctuating. Both the hydraulically actuated Lewa ecosmart diaphragm pump and heatable systems for additive metering will be displayed at K 2016, Oct. 19-26, in Düsseldorf.

The design of the metering system is optimized to account for the fact that the quality of the end product depends on the constant expansion of the blowing agents. Consisting of an Ecoflow metering pump, a suction-side strainer and two contact pressure gauges for pressure monitoring in the pipeline, the system is suitable for a pressure of 50 to 500 bar, allowing between 0.5 kg/hr and 250 kg/hr (1.1 lb/hr to 551 lb/hr) to be pumped.

Extruder RPM is selected as a reference value so that the metering pump conveys the blowing agents in a quantity proportional to the speed. The Smart Control system continuously compares the signal of the flow meter with the request signal and adapts the flow rate accordingly. To do so, the speed of the drive motor is regulated to correspond to the process requirements.

As a special feature, the controller memorizes the characteristic curve of the pump. This ensures the system can be balanced significantly more quickly than when a conventional PID controller is used. The pressure stiff characteristic curve of the pump guarantees precise metering, even when the extruder pressures are fluctuating.

A safety valve is also attached to protect the system from overpressure. Thanks to a robust, hermetically tight pump technology, the Ecofoam system achieves high levels of operating reliability. This results in minimized downtimes, requiring maintenance only once per year, as well as high levels of productivity.

Lewa will also have on display its ecosmart diaphragm metering pump. With an absolute suction pressure of up to 0.1 bar, the pump provides a wide array of safe installation options. The pump is able to achieve very high levels of metering accuracy regardless of the fluid being used as a result of adjusting the motor speed and because of the manual stroke adjustment option. The hydraulically actuated PTFE sandwich diaphragm is monitored by a diaphragm protection system during continuous operation. With discharge pressures of up to 80 bar, ecosmart is said to be suitable for metering of flame retardants, lubricants or plasticizers and can be used as a single pump to convey flow rates up to a maximum of 300 l/h.

For liquids that naturally display a wax-like consistency, Lewa has also developed heatable systems that are designed for a temperature range of up to 130 C and a pressure of up to 500 bar. These metering systems are ready for operation and suitable for a large variety of additives, including flame retardants, lubricants and static inhibitors as well as plasticizers. The system usually consists of single or multiple metering pumps as well as a filter, safety valve, pulsation damper and flow meter. The flow rates range from 0.1 kg to 200 kg/hr (0.2 lb to 441 lb/hr) whereby the fully automatic control ensures safe and flexible metering.

Related Content

Formulating LLDPE/LDPE Blends For Abuse–Resistant Blown Film

A new study shows how the type and amount of LDPE in blends with LLDPE affect the processing and strength/toughness properties of blown film. Data are shown for both LDPE-rich and LLDPE-rich blends.

Read MoreWhy Compression Ratio is Important

Compression ratios have been pretty much standardized over the years, based on what has typically worked before. But there are quite a few variables that must be considered in order to get the optimum performance from your screw.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreThe Importance of Viscosity in Melting

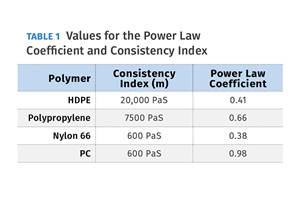

The calculations required to determine the right melt temperature for each polymer are complicated. Knowing the power-law coefficient and the consistency index of the polymer you run might prove useful.

Read MoreRead Next

How Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreProcessor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read More

(2).jpg;maxWidth=300;quality=90)