TPEs for Pet Toy Market

Teknor Apex’s tough and durable Monprene CP-16500 series boasts broad range of performance and aesthetic characteristics.

A new series of TPEs designed for the pet toy market is the latest addition to the Monprene TPE product line from Teknor Apex. The Monprene CP-16500 series of TPEs reportedly are durable and sustainable alternatives to thermoset rubber for dog toys, with a broad range of performance—hardness range of 25 to 65 Shore A, and aesthetic characteristics.

This series includes clear, translucent and opaque grades with low, medium and high gloss. All grades have been shown to exhibit excellent colorability and are easily moldable. This extensive portfolio includes general-purpose and specialty grades that offer improved durability with superior resistance to puncture and tear—ideal for the demanding applications of dog chew toys.

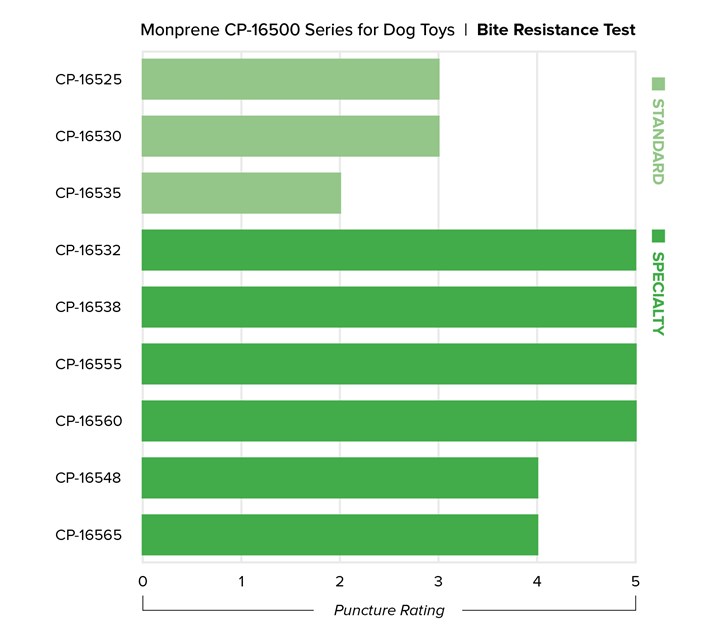

To help compare the durability of different materials, Teknor Apex designed a “bite resistance” laboratory test to simulate the forceful action of a dog biting a toy. Based on the ASTM test method F1306 for flexible films, the Teknor Apex Bite Resistance test measures the puncture resistance, or the force required to penetrate an injection molded specimen. A “Puncture Rating” is assigned to each material based on this force, and uses a scale of 1 to 5, with 5 having the greatest resistance. As shown below, the specialty Monprene gradesexhibit considerably high bite resistance.

While the general-purpose grades offer an excellent balance of cost and performance, the specialty grades offer superior resistance to puncture, tear, and tear propagation. All materials in this series reportedly mold with ease, with excellent flow characteristics. In the case that a pet product manufacturer has unique requirements, Teknor Apex will work with them to customize a Monprene TPE solution.

The Monprene CP-16500 series is formulated with only FDA listed ingredients and is not formulated to contain PVC, BPA, latex, phthalates or metals, nor REACH SVHC or Prop 65 listed substances. These grades are also classified and suitable for use in Children’s Toys per the following regulatory standards: Consumer Product Safety Improvement Act (CPSIA), European Product Safety Standard EN 71, and the ASTM International's Standard Consumer Safety Specification for Toy Safety (F963).

Monprene is also recyclable, offering a sustainable alternative to thermoset rubber dog toys. Scrap recovered from any step in the manufacturing process can be re-introduced into the process or used in the production of new parts. Additionally, used chew toys can be recovered, shredded, and recycled into new ones.

“Made in the USA” Monprene CP-16500 Series are manufactured in several ISO-9001 certified facilities in the USA, but are also manufactured in Singapore and Germany to serve local markets – all with strict formulation control and traceability.

Related Content

-

Fast-Cycling Selective Laser Sintering System

Nexa3D announced the QLS 260 for metal and polymer production.

-

Non-Fluorosurfactant Peroxide Curable Fluoroelastomers

Solvay launches new high-performance Tecnoflon FKM without use of PFAs used as process aids.

-

Tracing the History of Polymeric Materials, Part 25: Silicones

The long road to the development of silicone resulted in a chemistry that is remarkably versatile.

(2).jpg;maxWidth=300;quality=90)