Injection Know How

How to Establish an Acceptable Range for Pressure at Transfer

Pressure at transfer tells you the viscosity of the resin, providing the fill time is the same. Monitoring pressure at transfer—or better yet, the integral under the pressure vs. time curve—provides insight into the process.

Read MoreMinimizing Black Specks

Black specks in molded parts are one of the most infuriating problems to resolve on the shop floor. Here's how to fix them.

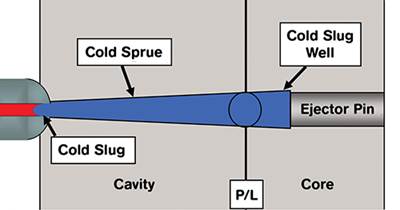

Read MoreDon’t Forget the Cold Slug Well

Its primary function—as the name suggests—is to act as a trap, or “well,” for the cold slug.

Read More‘Auto Compensate’ Your Press To Handle Viscosity Variations

Here's how to put your injection molding machine on cruise control to make consistently good parts even in the face of material viscosity variations.

Read MoreLevel Your Press in an Hour or Less

A level injection molding machine is necessary to keep producing high-quality parts. Here's how to do it right.

Read MoreWhat's Different About Molding Engineering Plastics

If you try to run them like commodity materials such as PP you'll have problems.

Read MoreTake a Scientific Approach to Troubleshooting

Taking a scientific approach minimizes the 'art' of molding, which is particularly helpful when troubleshooting

Read MoreScrew Decompress Before Screw Rotate

Thoughtfully determining when to start screw rotation to build the charge for the next shot can reduce the wear and tear on the screw tip, check valve, and screw motor.

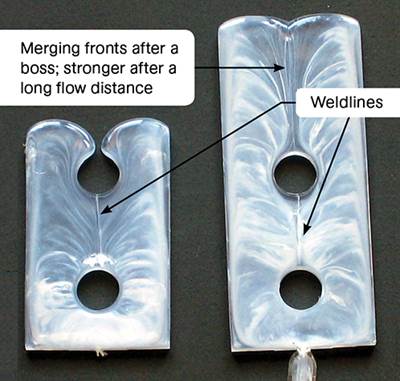

Read MoreCoping with Weak Weld Lines

Weld lines cause significant reject rates and are a common problem that all molders face.

Read More

.png;maxWidth=300;quality=90)