Injection Know How

Getting Good Data from DOE

How do you know what process variables control a part’s dimensions or other properties? A properly conducted DOE is the answer—but incorrect procedure will yield useless data.

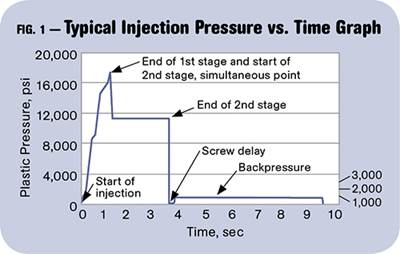

Read MoreImprove Profits by Graphing Injection Pressure

Graphing is a powerful aid in optimizing the process and troubleshooting both process and machine issues.

Read MoreWhat to Calibrate on Your Press

There are different approaches to meeting the goal of making parts identically. At the heart of all them is the process or the machine setup sheet. My bet would be you cannot find two that are identical.

Read MoreWhy Multi-Cavity Molds Fill Unevenly

Balanced filling is critical for making identical parts, achieving high CPKs, holding tight tolerances, and getting “good” data from design of experiments.

Read MoreWhat Percentage of Barrel Capacity Should Your Shot Size Be?

The answer combines both experience and science, and it may be one of those molding details that gets overlooked but could be stealing a chunk of your profits.

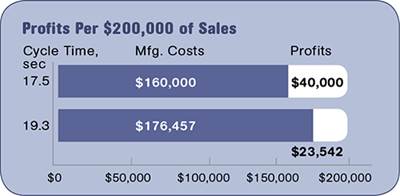

Read MorePlasticating Rates: Your Profits Are at Stake

To get the best cycle time you need the right machine, and few molders take the time to specify this critical component of the process.

Read MoreCalculate Shot Size Vs. Barrel Capacity

It may seem like a dull topic, but it will overcome the emotional experience that follows when you put a new mold into a machine and you find out there is not enough barrel capacity to make a full shot.

Read MoreShort Shots Redux

Deliberately making a short shot permits you to do a scientific molding viscosity curve. It will also prevent you from damaging the mold by overpacking if you set shot size incorrectly.

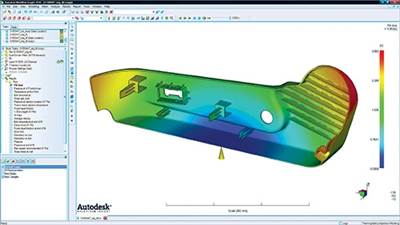

Read MoreMold Filling Simulation: What, When, Why, How

Mold-filling analysis is the right direction to go, but if you want to arrive at your destination—good parts and an efficient process—you’ll need to pay attention to all the details and select an experienced professional to do the analysis.

Read MoreScrews and Pellets: One Size Does Not Fit All

Screw design, pellet type/size and material behavior are all critical issues to consider to deliver uniform melt to the mold.

Read More

(2).jpg;maxWidth=300;quality=90)