Plastics Industry Automation

Automation in the Plastics Industry involves robots, cobots, molding cells, part pickers, and end-of-arm-tooling.

ESSENTIAL READING

VIEW ALLSmall Shops, Big Gains: How To Know If You’re Ready for Automation

In injection molding, automation is often seen as a tool for large companies with complex processes and high-volume production, but that mindset misses a broader truth: Automation can benefit molders of all sizes — even those running low-volume or straightforward jobs.

Read MoreWhat to Look for in High-Speed Automation for Pipette Production

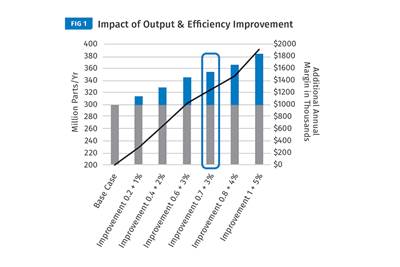

Automation is a must-have for molders of pipettes. Make sure your supplier provides assurances of throughput and output, manpower utilization, floor space consumption and payback period.

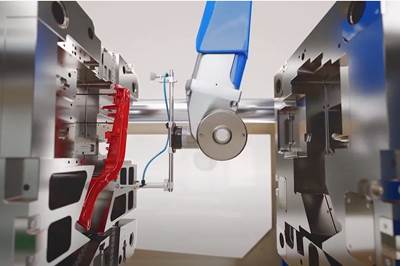

Read MoreHow to Automate High-Precision ‘Micro’ Insert Molding

What does it take to automate a horizontal injection molding cell to handle micro-sized inserts and molded parts? General-purpose top-entry robots and tooling may not be up to the job.

Read MoreHow to Plan and Implement Automation in an Injection Molding Plant

There is no “one size fits all” solution in automation. When considering what it would look like in your plant, hone in on the staff, products, space, and goals that are specific to you and the automation system that you will be installing.

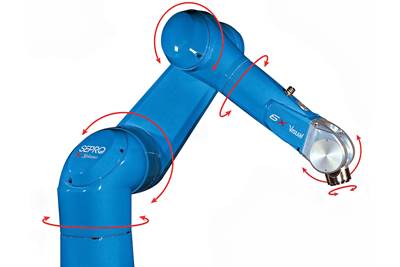

Read MoreAUTOMATION—PART 2 When to Consider Six-Axis Articulated-Arm Robots

Extraordinary versatility suits articulated-arm robots to a wide variety of operations, from loading inserts and unloading parts to decorating, assembly and testing. They also pair well with Cartesian robots. Many mounting options and improved speed and ease of programming add to their flexibility.

Read MoreHow to Make Your Pneumatics ‘Smart’

Emerson’s Avantics Smart Pneumatics Analyzer digitizes the analog pneumatic environment and monitors and analyzes key operating data.

Read MoreLatest Automation News And Updates

Coperion Expands Predictive Maintenance Platform

New component enables predictive maintenance planning, thus increasing a line’s OEE. At K 2025, Coperion will also demo new extruder condition-monitoring system.

Read MoreNext-Generation MES Applies AI

BMSvision will mark its 50th anniversary by introducing its latest manufacturing execution systems (MES) at K 2025, applying artificial intelligence (AI) and machine learning (ML).

Read MoreSepro Launches Revamped Robot Line and Controller

Sepro will debut the faster more power S-Line robots and a fully revamped Visual 4 controller at K 2025.

Read MoreArburg's K Focus: Sustainability, Digitalization, Automation

With some debuts still under wraps at press time, Arburg says attendees will find answers to pressing questions around sustainability, digitalization and automation at its K 2025 booth.

Read MoreAI and Tiebarless Debuts for Engel

The latest generation of its electric tiebarless victory injection molding machines, inject AI process assistance and AI-powered machine support via its e-connect portal, will debut at K 2025.

Read MoreSumitomo (SHI) Demag Plans for ‘Electric’ K 2025

Debuts include an all-electric multicomponent IntElect 350t combined with a SAM-C20 robot and two high-speed PAC-E machines targeting high-speed packaging applications.

Read MoreFeatured Posts

How This Custom Compounder Leverages AI to Drive Innovation, Sustainability

Alterra has stepped up its cutting-edge Industry 4.0 technology with its own AI platform to further increase its efficiencies.

Read MoreChoosing the Right Projects to Automate

What are the strategies and upfront work that go into identifying production problems that could benefit from an automation solution?

Read MoreWhy Are Cobots Popping Up in Injection Molding Processes?

Collaborative robots (cobots) can play a vital role in broadening a plastics processor’s automation portfolio.

Read MoreICYMI: July Roundup

BBQ, fireworks and best practices: Here’s a quick look at the top articles from July you might have missed.

Read MorePursuing Paperless: Injection Molders Who Have Embraced Digitization

Read about injection molders who have shifted everything from quality control and scheduling to production and process monitoring to the digital realm.

Read MoreArt or AI?

Is AI a tool that humans can use to increase their efficiency or a replacement for them altogether?

Read MoreFAQ: Automation

How to add automation to injection molding?

There is no “one size fits all” solution in automation. When considering what it would look like in your plant, hone in on the staff, products, space, and goals that are specific to you and the automation system that you will be installing.

Automation Supplier Categories

- Rebuilt Screws or Barrels

- Automation/Systems Integration

- Drive Controls

- Recording Instruments

- Troubleshooting, Problem Solving Systems

- Machining, Routing Software

- Materials Formulating Systems

- SPC, SQC Systems

- Product & Tool Design, Analysis Software (CAD/CAM/CAE)

- Maintenance Management Systems

- Rebuilt Motors & Drives

- Scheduling, MRP, Production & Inventory Management Systems

- Job Estimating Software

- ISO 9000 Software

- Dewpoint Monitors/Moisture Analyzers

- Parison Programmers

- Flow Monitoring/Control Devices (for Liquids)

- Pressure Controllers, Monitors

- Controllers, Monitors

- Color Matching/Formulating Systems

- Training & Workforce Development Services/Software

- Sensors, Thermocouples

- Design of Experiments (DOE) Software

- Motion or Position Controls

- Screw Design/Analysis Software

- Level Sensors & Controls

- Closed-loop Process Control Systems

- Used Machinery

- Machine Monitoring/Alarm Systems

- Trade Assciations, Agencies, Societies

- Pressure Sensors, Transducers