Gas-Water Assist Injection Molding

Latest Gas & Water Assist Articles

VIEW ALLFakuma 2023: Wittmann Battenfeld Expands All-Electric Line, Direct-Current Capabilities

Wittmann Battenfeld will introduce the new EcoPower B8X injection molding machine line and show direct current as an energy source for a concept machine that will power its own robot.

Read MoreInternal Gas Pressure Molding Offers Sustainability Benefits

Wittmann Battenfeld says its upgraded Airmould 4.0 technology, which features a more compact footprint, saves material and cycle time — thereby also cutting energy use.

Read MoreStructural Foam Injection Molding Line Extended

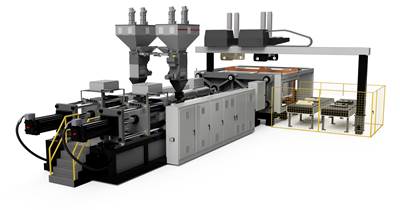

At K 2022, Wilmington Machinery introduced the dual-injection Lumina MP1200 medium pressure molding machine.

Read MoreUpgraded Low-Pressure Foam Presses With Elevated Bases

Updating low-pressure horizontal foam-molding presses with elevated bases.

Read MoreFakuma: Wittmann Battenfeld to Launch Machine Line at Friedrichshafen Fair

In addition to introducing its new SmartPlus line of servo-hydraulic injection molding machines, Wittmann Battenfeld will feature multiple machines at its booth and stream video of other cells from its labs.

Read MoreData Driven, Employee Owned

Approaching its seventh decade in business, PTA Plastics has shifted its location and remade its customer base since its founding in 1953, but many things have not changed in the intervening years, including an emphasis on people and leading-edge technologies.

Read MoreLatest Gas & Water Assist News And Updates

Linde Sells Industrial Gas Business to Messer Group

German industrial gas specialist acquires Linde portfolio of plastics molding and foaming technologies.

Read MoreNew Physical Foaming Process for Injection Molding

Linde will introduce a new physical foaming process for injection molding and show off CO2-based gas-assist and mold-cooling technologies.

Read MoreInjection Molding: Industry 4.0 Advances at Fakuma 2017

At October’s Fakuma fair in Germany, several injection machine suppliers will showcase their progress toward Industry 4.0 connectivity.

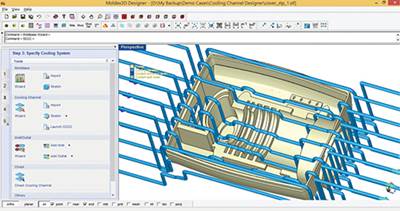

Read MoreINJECTION MOLDING: Mold Simulation Software Gains Speed and New Functionality

It's faster, easier to use, and supports more sophisticated modeling.

Read MoreFeatured Posts

Water Injection Beats Gas Assist in Lightweighting Car Door Panel

Renault’s conversion from metal-frame construction to plastics prototype switched from gas assist to water injection. Here’s why and how.

Read MoreSumitomo’s Theme: Productivity + Flexibility + Reliability

Sumitomo Demag aims to demonstrate a combination of speed, flexibility, proprietary technologies, and automation with six machine cells running at NPE2018.

Read MoreLifetime Achievement Awardee Honored For Over 30 Years of Advances in Automotive Molding

Technical specialist Dr. Suresh Shah, who holds more than 45 Intellectual Properties including patents and trade secrets, was recognized at SPE Automotive Innovation Awards Gala.

Read MoreMack Molding Adds ‘Largest Press in New England’

The 2360-ton Haitian press has a 268-oz shot capacity and the ability to handle 40,000-lb molds.

Read MoreVIDEO: A Look Back at Molding 2017

John Bozzelli’s workshop; RocTool’s Open House; an interview with Bruce Main; and insights from conference co-chairs Matt Naitove and Tony Deligio.

WatchWhat's Out There, What's Coming and Trying to Know What You Don't

Leading companies do three things consistently when it comes to technology.

Read More

.png;maxWidth=300;quality=90)