Plastics Use in the Medical Industry

Plastics play a huge part in the medical industry, including in catheters, IV bags, blood bags, ventilators, syringes and hospital beds.

ESSENTIAL READING

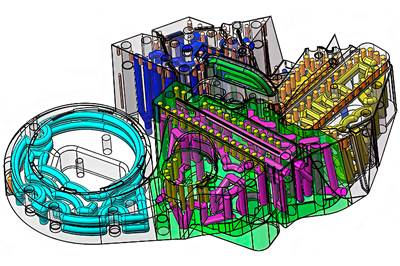

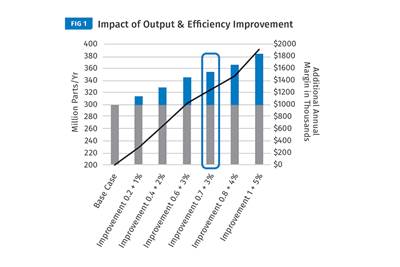

VIEW ALLHow to Know the True Value of Conformally Cooled Injection Molds

What’s the return on investing in a new mold with conformal cooling to boost productivity? Will it pay for itself? How soon? Here’s a case study on how to answer those questions.

Read MoreWhat to Look for in High-Speed Automation for Pipette Production

Automation is a must have for molders of pipettes. Make sure your supplier provides assurances of throughput and output, manpower utilization, floorspace consumption and payback period.

Read MoreProtolabs Addresses How to Survive a Pandemic with Digital Manufacturing

Protolabs survey results examine product development and the supply chain.

Read MoreProcessing Medical Plastics? Here's How to Minimize Risk

FDA now expects OEMs of healthcare products to also take responsibility for Tier 2 and 3 suppliers—making sure every supply-chain link is meeting Good Manufacturing Practices.

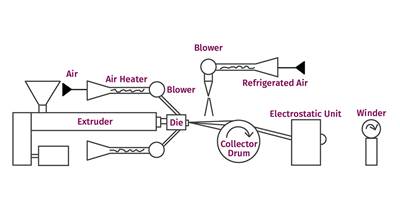

Read MoreExtrusion: 'Melt-Blown' Fiber: What You Need to Know to Enter the Face Mask Market

Coronavirus pandemic has made extrusion processors curious about entering the face-mask market. But melt-blown fiber is very different from most other extrusion processes and requires specialized equipment.

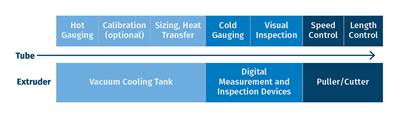

Read MoreHow to Improve Production of Catheters and Stents

Advances in downstream extrusion equipment have boosted production control.

Read MoreLatest Medical News And Updates

Krones Acquires Netstal

Krones adds PET preform injection molding to its bottle blowing and filling capabilities, as well as cap molding and expansion into medical, food and other markets.

Read MoreArterex Acquires Micromold

The medical device contract manufacturing company with eight facilities globally has purchased the Riverside, California-based micromolder.

Read MoreNorthwell Health Installing Technology to Treat Medical Waste On-Site to Facilitate Recycling

Envetec’s Generations technology will shred and disinfect waste materials that can then be recycled.

Read MoreBaxter to Scale Up PVC Intravenous Bag Recycling Program

Successful pilot program with Northwestern Medicine will expand to additional units and health systems.

Read MoreFakuma 2023: High-Speed Pipette Tip Molding

Sumitomo (SHI) Demag, Hekuma and Schöttli partnered on production cell molding pipette tips from a 32-cavity mold in a cycle of 4.5 seconds.

Read MoreMedical-Grade Antimicrobial Masterbatch

Developed to protect plastic components in health care facilities against the proliferation of microorganisms.

Read MoreFeatured Posts

Catheter Specialist Finds Sweet Spot Serving Small, Medium-Sized Concerns

Medical-component specialist LightningCath has carved a niche meeting the needs of small to medium-sized entrepreneurs with complex catheter designs … quickly.

Read MoreMedical Molder, Moldmaker Embraces Continuous Improvement

True to the adjective in its name, Dynamic Group has been characterized by constant change, activity and progress over its nearly five decades as a medical molder and moldmaker.

WatchMedical Manufacturer Innovates with Additive Manufacturing and Extrusion Technology Hubs

Spectrum Plastics Group offers customers two technology hubs — one for extrusion, the other for additive manufacturing — to help bring ground-breaking products to market faster.

Read MoreUse Cavity Pressure Measurement to Simplify GMP-Compliant Medical Molding

Cavity-pressure monitoring describes precisely what’s taking place inside the mold, providing a transparent view of the conditions under which a part is created and ensuring conformance with GMP and ISO 13485 in medical injection molding.

Read MorePlastic Compounding Market to Outpace Metal & Alloy Market Growth

Study shows the plastic compounding process is being used to boost electrical properties and UV resistance while custom compounding is increasingly being used to achieve high-performance in plastic-based goods.

Read MoreAs Currier Grows in Medical Consumables, Blow Molding Is Its ‘Foot in the Door’

Currier Plastics has added substantial capacity recently in both injection and blow molding for medical/pharmaceutical products, including several machines to occupy a new, large clean room.

Read More

.png;maxWidth=300;quality=90)