Tooling for Plastics Production

Tooling for plastics production includes molds, mold components, ejector pins, mold bases, nozzles, mold cores, mold cavities, conformal cooling.

Narrow Your Tooling Search

ESSENTIAL READING

VIEW ALLAIM Institute Continues to Grow Plastics Education and Training on 10th Anniversary

The AIM institute was created in response to the rising need for skilled injection molding professionals, providing individuals with a fundamental understanding of plastic rheology and plastic flow through a mold.

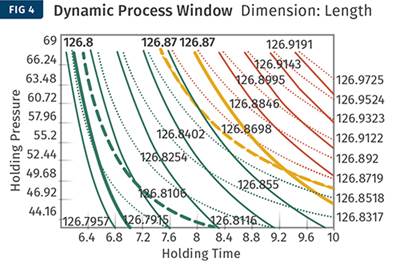

Read MoreOptimizing Pack & Hold Times for Hot-Runner & Valve-Gated Molds

Using scientific procedures will help you put an end to all that time-consuming trial and error. Part 1 of 2.

Read MoreWhat You Need to Know About Leader Pins and Bushings

There’s a lot more to these humble but essential mold components than you might suspect. Following the author’s tips could save much time, money and frustration.

Read MoreThree Key Decisions for an Optimal Ejection System

When determining the best ejection option for a tool, molders must consider the ejector’s surface area, location and style.

Read MoreBest of Fattori, Tooling Know How

In this collection of articles Jim Fattori offers his insights on a variety of molding-related topics that are bound to make your days on the production floor go a little bit better.

Read MoreHow To Design Three-Plate Molds – Part 4

There are many things to consider, and paying attention to the details can help avoid machine downtime and higher maintenance costs — and keep the customer happy.

Read MoreLatest Tooling News And Updates

Dry-Ice Pelletizer Offers Efficiency and Portability

PCS Company now offers the SUR-120, which has an oil-free design to minimize maintenance and produce contamination-free dry ice for sensitive industries.

Read MoreNo Platens, No Problem: Mold-Masters and Partner Mold Without Press at K 2025

The fully integrated cell molded medical parts from a side-gated hot runner system without the platens, tie bars and mold open/close normally associated with injection molding.

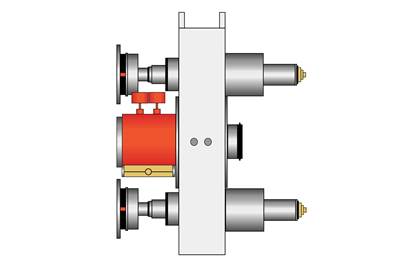

WatchMulticoupling Device Tackles Medical Moldmaking Problems

Stäubli SMI209 targets cross-connection errors, inconsistent setup, water leaks and staffing shortages to meet demands for medical injection molding.

Read MorePTXPO 2026 Opens Registration

Gain a competitive edge at this premier industry event featuring technical education, networking and exhibits to spur innovation and advancement in plastic mold manufacturing.

Read MoreHaidlmair Highlights Moldmaking Productivity K 2025

Haidlmair will demonstrate patented mold technology designed to enhance productivity with faster setup, optimal cooling and greater energy efficiency.

Read MoreHasco Unveils Precision Stamps, Space-Saving Insert

Fixed-height stamps with recessed engraving promise consistent quality while compact 12-zone plug insert saves space with full 16-amp capacity.

Read MoreFeatured Posts

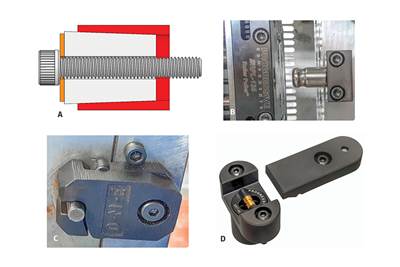

Traceability: The Why and How of Using Date Stamps in Molds

Whether the product you’re molding is required by regulations to include a date stamp or you see the production transparency benefits of applying them, there are important elements to understand in managing these tool inserts.

Read MoreMPM’s Second Act: Keeping Injection Molding, Moldmaking in the Midwest

Larry Austin’s 35 years at a highly successful injection molding company inform much of what he does and doesn’t want in his second act in plastics owning an injection molding company.

Read MoreHow 3D Printing Supports Toolmaking Workforce at This Multiscale Molder

At more than a century old, General Pattern has seen multiple evolutions in its business — the latest of which is the embrace of additive manufacturing technologies for mold tooling and beyond.

Read MoreOptimizing Pack & Hold Times for Hot-Runner & Valve-Gated Molds

Using scientific procedures will help you put an end to all that time-consuming trial and error. Part 1 of 2.

Read MoreThe Connector Conundrum: 3D Printed Mold Tooling’s Role in Innovation

ReelView Fishing faced an electronics obstacle in the development of its new technology for underwater video. Additive manufacturing for moldmaking allowed for the speed necessary to iterate to a solution. How inventors and invention will benefit from new ways of obtaining production-ready tooling.

Read MoreDesign Your Tools for Moldability ... and Maintenance

In the initial design phase, when considering the structure and elements of the tool, are you designing them to be maintenance friendly? Canon Virginia has used this approach and preventive maintenance to make tool replacement a thing of the past. You can, too. Here’s how.

Read More