New developments such as brand identity, e-commerce, sustainability and lifestyle are impacting bottle design. Rapidly evolving consumer demands, along with strict retail and regulatory requirements, are driving packaging companies to push the boundaries of what a bottle can be. While evolving design tools allow designers to be more creative and help customers achieve their unique brand identity through shape, embossing and etching, there’s more to it than that.

When a customer approaches a packaging company with a new bottle concept, there are multiple critical engineering and design methodologies that are deployed long before the final product reaches the customer. Bottle design and development take into consideration the entire product life cycle, including its performance throughout the supply chain.

To ensure a successful development, all stakeholders must come together at the start of the project to establish the goals, functional requirements and desired outcomes for each new bottle design—as well as identify any limitations or complex challenges associated with fulfilling those goals.

This process not only ensures the desired outcome for the brand and bottle, but it also allows the packaging company to create a work plan that can streamline the manufacturing process while offering a more sustainable, cost-effective solution. To build a better bottle, there are a number of process steps and common factors that designers and engineers must consider toward achieving desired outcomes.

There are multiple critical engineering and design methodologies that are arranged long before a final package reaches a customer. Whether through design, performance or process, each bottle brings its own unique set of requirements.

Establishing the Blueprint for Bottle Design

The first step in designing a new bottle is to bring together all stakeholders— including both brand and engineering teams—to engage in an initial “discovery session” to capture all packaging requirements. These sessions help gauge each stakeholder’s goals for the product, identify potential challenges and determine how they will be addressed during product development. The discovery session is particularly valuable in identifying true requirements versus other features that may be desirable but not necessary and helping to prioritize trade-offs (e.g., the desire for a more rigid side wall versus the desire to reduce overall bottle weight).

Bottle design and development take into consideration the entire product life cycle, including its performance throughout the supply chain.

Packaging companies walk customers through the bottle life cycle to understand the requirements of the bottle and then apply those requirements toward defining a specification. The product life cycle includes the filling line and how the bottle is conveyed, filled and capped, the labeling system and how the finished container is packaged (e.g., cases or tray pack). Also discussed is the consumer experience. Where will the product be sold (convenience store, vending machine, etc.)? In other words, there are multiple “touch points” for the bottle that are critical to how it functions and performs to maintain its desired shelf appearance and meet the end user’s needs.

When designing a bottle, one of the first steps is to bring together stakeholders and hold a “discovery session” to capture all packaging requirements, including the brand’s goals, potential challenges and more.

The product development engineer is responsible for creating a development specification while ensuring alignment with customer requirements. The development specification includes material/barrier requirements, type of filling process, package performance requirements, dimensional aspects of the package, and how the product will be delivered to the customer.

The development specification also allows the technical team to establish both knowns and unknowns (i.e., what needs to be learned during the development process) so these issues can be explored and refined. Throughout the process, there are a series of review steps that allow team members to collaborate and share knowledge to satisfy stakeholders with the final specification and product.

Specification Drives All Phases of Bottle Development

Establishing and reviewing a development specification with the customer is critical to the outcome of the final product. For example, a recent project for a multi-serve bottle included side grips for the consumer to grab and use the bottle. The specification discussion eventually led to how the bottle would be oriented on the pallet when delivered to the customer. The orientation of the grips was critical to maintain alignment with the customer’s filling and labeling equipment.

This aspect of specification was key to ensuring the packaging company’s production line was capable of providing the proper orientation for the front and back panels. Knowing these requirements early in the development process rather than during a filling-line trial saved added time and labor costs that would have been incurred during production.

Another instance involved a design for a hot-fill package. Because it was hot-fill, the bottle design required design elements (vacuum panels). The traditional approach is to optimize vacuum-panel design by focusing only on the post-hot-fill performance of the package, when the product cools and contracts, creating a vacuum in the container. However, it is possible to go too far and create a condition where the vacuum panels bulge. This could create a situation where the bottles cannot be handled properly on the customer’s filling line.

Establishing and reviewing a development specification with the customer is critical to the outcome of the final product.

In this case, early specification alignment with customer requirements provided greater insight into the product’s full life cycle, helping designers identify performance requirements that were unique to the package and the filling process. Having access to this knowledge drives simulation and shape optimization and gives manufacturers the ability to avoid costly mistakes and delays during the later stages of the development process.

The Five Phases of Bottle Development

Once the initial development specification has been established, the engineering team begins working through each phase of development. These include shape development, engineering design, prototyping, validation and execution.

A number of tools and technologies are used during the five phases of development—including establishing both knowns and unknowns—to ensure both optimization of the product/process and transformation of the development specification to a production specification. When complete, the specification serves as the road map throughout the development process and is the common link between the various phases.

- Shape Development Captures Customer Requirements: Designers then use that road map to inform shape development. There are a variety of customer specifications that contribute to shape development. These specifications can include elevating brand identity at point of purchase, increasing sustainability and reducing logistical costs with a package that is lighter and/or smaller without reducing fill weight. Using digital modelin

g, designers can take all requirements from the development specification and create a virtual 3D model of the product that can be tested under various conditions. It can also uncover why a specific design may be sensitive to material distribution.

Each packaging company may have a different approach to shape development. The key to achieving the optimal design for a customer is understanding how the design impacts the manufacturing process (what will work and what won’t work) and how design elements may impact structural performance. By focusing first on blow molding technologies, designers have the ability to incorporate certain design elements into a bottle that is manufacturable, while still satisfying the desired aesthetics for the customer.

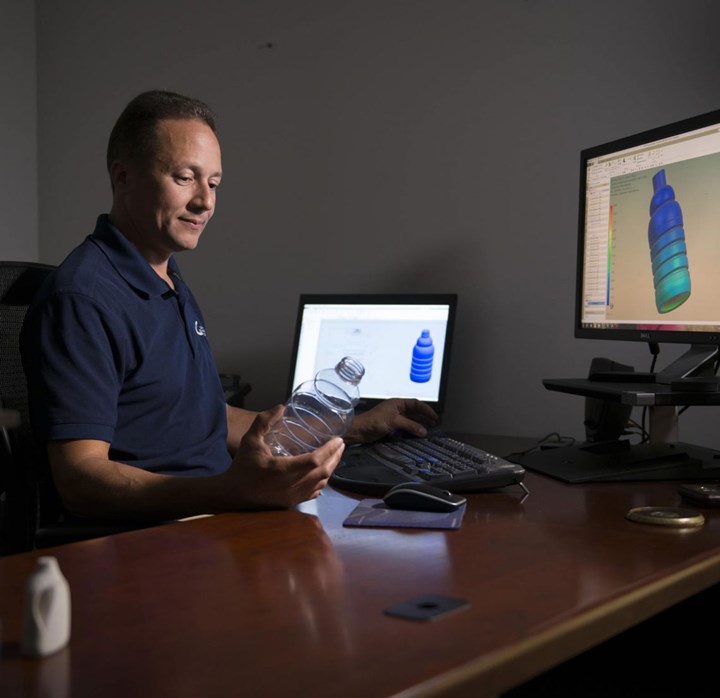

- Applying Digital Modeling and Simulation in the Engineering Design Phase. After package shape has been established, engineers begin virtually testing the bottle’s performance against the expectations set in the specification, including design, dimensional and functional requirements. Design and simulation engineers complete several iterative design loops to optimize the shape and material distribution to achieve the desired performance.

During the engineering and simulation phase, the team uses finite-element analysis to enhance shape and material distribution and identify the limits for dimensional aspects of specification. Recent advances in blow molding technology give packaging companies the freedom to control at a much finer precision and resolution. This allows engineers to remove additional material from a package that was previously required to accommodate machine variability. After modeling and simulation are complete, engineers begin developing a prototype for testing.

Using digital modeling, designers can take all requirements from the development specification and create a virtual 3D model of the product that can be tested under various conditions.

- Prototyping: Prototyping includes building a prototype mold and producing functional bottle samples that can be physically tested to understand the performance of the bottle.

These samples can also run on a customer’s filling line to test bottle performance or make adjustments to the customer’s line. In some instances, the customer’s line is brand new and these samples can help the customer and other vendors fine-tune their equipment. A physical sample at this point in the development process is also very helpful in showing the customer what to expect long before commercialization.

Prototyping can also provide a feedback loop to simulation, which allows for refinement of simulation tools and methods to improve accuracy, which could eventually lead to the elimination of the prototyping step by relying on simulation alone.

- Validation Confirms Specification Compliance and Bottle Performance: While the validation process can vary between packaging companies, it typically involves running a lead mold on the actual production machinery. This could be an existing asset in one of the production plants or a new machine and mold set fabricated by a vendor partner. Either way, the validation process ensures the correct mold engineering and helps fine-tune the blow molding equipment and production line. This phase ends with a transition to routine, ongoing operations and full customer acceptance of the new bottle.

- Intelligent Factories Enhance Execution: Successful execution requires validating that the production line is fully capable of meeting customer requirements and the operations team has optimized process settings and standard operating conditions so they can move into routine production.

This final phase of the process has become more efficient due to the rapid introduction of intelligent or “smart” factories that leverage the fast-growing array of Industry 4.0 (or Internet of Things, IoT) technologies. IoT-equipped “intelligent factories” can improve production performance while bringing additional efficiencies and sustainability to the packaging process.

IoT technologies allow engineers to monitor production of the bottle during live manufacturing rather than measuring the bottles after they are produced (and it is too late to catch a problem). IoT allows for monitoring of certain process variables that impact different parts of the specification. For example, engineers can set process limits and monitor the blow molding pressure—knowing that if it drops below a certain point, it may impact material distribution. Catching this fault during the process allows adjustments to be made in real time rather than after the product run is complete. These optimizations result in greater production efficiencies to lower operating costs.

Each Bottle Brings a New Opportunity

One of the more challenging aspects of packaging development is that no two bottles are identical. Whether through design, performance or process, each bottle brings its own unique set of requirements. While there may be similar expectations within a vertical market, customers continue to seek out differentiation through their packaging to enhance sales at point-of-purchase.

New, smart technology can also help shorten the overall timeline from engineering design through execution and ensure a faster and smoother transition to production. As packaging companies continue to incorporate higher levels of post-consumer recycled (PCR) content in bottles while maintaining performance standards, the precision and reliability afforded by intelligent technologies allow companies to deliver sustainable solutions without compromising design, performance or cost. This is particularly true when brands convert from glass or aluminum to plastic packaging.

As technologies continue to evolve, product-development engineers will delve deeper into their processes to learn what drives the functional characteristics for a particular package. Advances in blow molding technology give packaging companies the ability to think outside the bottle and bring new designs to market that deliver greater shelf appeal while offering new levels of sustainability.

Brands looking to optimize their package design should look for a packaging company with a history of bringing innovative designs to market. Their process should take a holistic approach to understanding the complete life-cycle requirements of the package—from concept to consumer—to reduce supply-chain costs while elevating sales.

ABOUT THE AUTHORS: Justin Howell is a principal engineer with Graham Packaging and has been with the company since 2002. Over that time, he has served the Engineering and Product Development organization with various roles in design engineering and R&D.

John Hillenbrand joined Graham Packaging in 2019 as v.p. of PET engineering and development. He has 10 years of experience in the packaging industry, spanning both flexible and rigid markets. His career experiences include DuPont, Owens Corning and Armstrong Flooring.

Related Content

How to Extrusion Blow Mold PHA/PLA Blends

You need to pay attention to the inherent characteristics of biopolymers PHA/PLA materials when setting process parameters to realize better and more consistent outcomes.

Read MoreFormulating LLDPE/LDPE Blends For Abuse–Resistant Blown Film

A new study shows how the type and amount of LDPE in blends with LLDPE affect the processing and strength/toughness properties of blown film. Data are shown for both LDPE-rich and LLDPE-rich blends.

Read More‘Monomaterial’ Trend in Packaging and Beyond Will Only Thrive

In terms of sustainability measures, monomaterial structures are already making good headway and will evolve even further.

Read MoreYoung Stretch-Film Processor Bets on Nanolayers

Going up against companies with as much as double its capacity, young stretch-film processor Zummit believes that new technology — notably 59-nanolayer films — will give it a competitive edge.

Read MoreRead Next

How Graham Packaging Counters PCR Supply/Demand Squeeze

Customers want more PCR—including food grade—than recyclers can supply. Solutions involve efforts to educate customers, employees, and the community at large. New technologies also offer hope.

Read MoreHow Graham Packaging is Helping to Create a Circular Economy for Plastic Packaging

Graham Packaging’s Tracee Reeves talks with Plastics Technology about ways the company is working to encourage recycling, improve product recyclability and increase offerings with recycled content.

Read MoreGraham Packaging Commits to 100% Reusable, Recyclable or Compostable Packaging by 2025

Part of the Reynolds Group, Graham Packaging has signed the Ellen MacArthur Foundation’s New Plastics Economy Global Commitment

Read More