Extrusion/Compounding at NPE2018: More…More…More!

More speed, flexibility and robustness. Across a gamut of extrusion applications, machine builders are introducing new machinery, components, and systems to dramatically raise the bar on productivity.

Extrusion processors want more. That’s evident by what suppliers of extrusion and compounding systems and equipment are bringing to NPE2018. Here a guide to what’s new in extrusion and compounding at the giant show, divided by product and process type.

NEWS IN SINGLE-SCREW EXTRUDERS

Davis-Standard says the star of its NPE booth is a running TPE tubing line that shows the benefits of preventive and predictive maintenance as part of a global trend toward the “smart factory.” Davis-Standard (D-S) will provide real-time examples of the advantages of this technology, including direct e-mail notifications to customer PCs, tablets or smart phones during the show. The line will be processing TPE tubing for industrial applications and will feature the company’s newest Thermatic extruder design along with the DS eVUE II controller.

Examples of preventive-maintenance monitoring include vibration, oil composition, motor parameters, heater status, screw wear and energy consumption. As part of this package, the line will feature Davis-Standard’s latest drive technology to provide notification of potential drive issues. The 2.5-in. Thermatic is an upgraded model with enhancements in gearbox design, barrel cooling and vent-diverter geometry.

D-S will also be showing a next-generation 2.5-in., direct-drive, grooved-feed extruder featuring its proprietary Helibar design. This machine has a grooved intake zone and helically grooved barrel, along with new barrier-mixing screw technology. This barrel and screw combination offers increased processing flexibility due improved pressure stability and tolerance for higher regrind levels. It also enables processing of a wider range of polymers at lower pressure and with improved energy efficiency.

The Helibar design is also said to be advantageous in terms of higher throughput, improved melt-pressure buildup, lower melt temperatures, improved melt homogeneity, reduced barrel wear, and shorter residence time. This extruder is said to be suited for pipe, profile, sheet, and blow molding.

The Super Blue extruder line will also be featured at the show. D-S says this extruder series offers processors the ability to switch among D-S feedscrews while offering a low-noise, a double-reduction gearbox, minimal maintenance, and consistent production rates. It is available in sizes from 2 to 4.5 in., each with the option of a 24:1 or 30:1 L/D. At NPE2018, the Super Blue will be equipped with the DS-eTPC II, the second generation of Davis-Standard’s touchscreen control.

This controller is aimed at pipe, profile, tubing, elastomer, wire/cable, sheet, and reclaim extrusion. Notable enhancements include a larger, 15-in. viewing screen with multi-touch capabilities for zoom-in and out, control of up to three extruders, and real-time and historical data trending.

Graham Engineering Corp. will be displaying a 2.5-in. (63.5-mm) American Kuhne Ultra extruder with XC100 Navigator control, and a 3.5-in. (99-mm) extruder with XC200 Navigator control. Graham has made improvements to its Ultra extruders to simplify maintenance. Examples are newly designed barrel covers that allow for quick and easy access to barrel heaters and thermocouples, and an automotive-style wiring harness with quick-change plugs for routing wiring and thermocouples from the electrical cabinet to the barrel-heater/cooling zones.

Navigator controls were originally developed for Graham Engineering extrusion blow molding systems and then adapted for Welex sheet extrusion lines. There are three levels of functionality: XC100 for stand-alone extruders; XC200 for one or more extruders in simultaneous operation; and XC300 for integrated production lines with the extruder and downstream components such as a puller, water bath, or winder. All three controls will be shown on American Kuhne extruders.

Graham will also display an American Kuhne three-layer medical tubing line, consisting of modular micro extruders, an American Kuhne AKcent coextruder, and XC300 Navigator with integrated TwinCAT Scope View high-speed data-acquisition system. This versatile customized system is available in fixed horizontal versions or units that can be fully tilted from horizontal to vertical. An EZ-Tilt feature makes angular adjustments quick and easy. The control panel is on located on an arm mounted to a ground post allowing the panel to swivel around the post for flexible positioning.

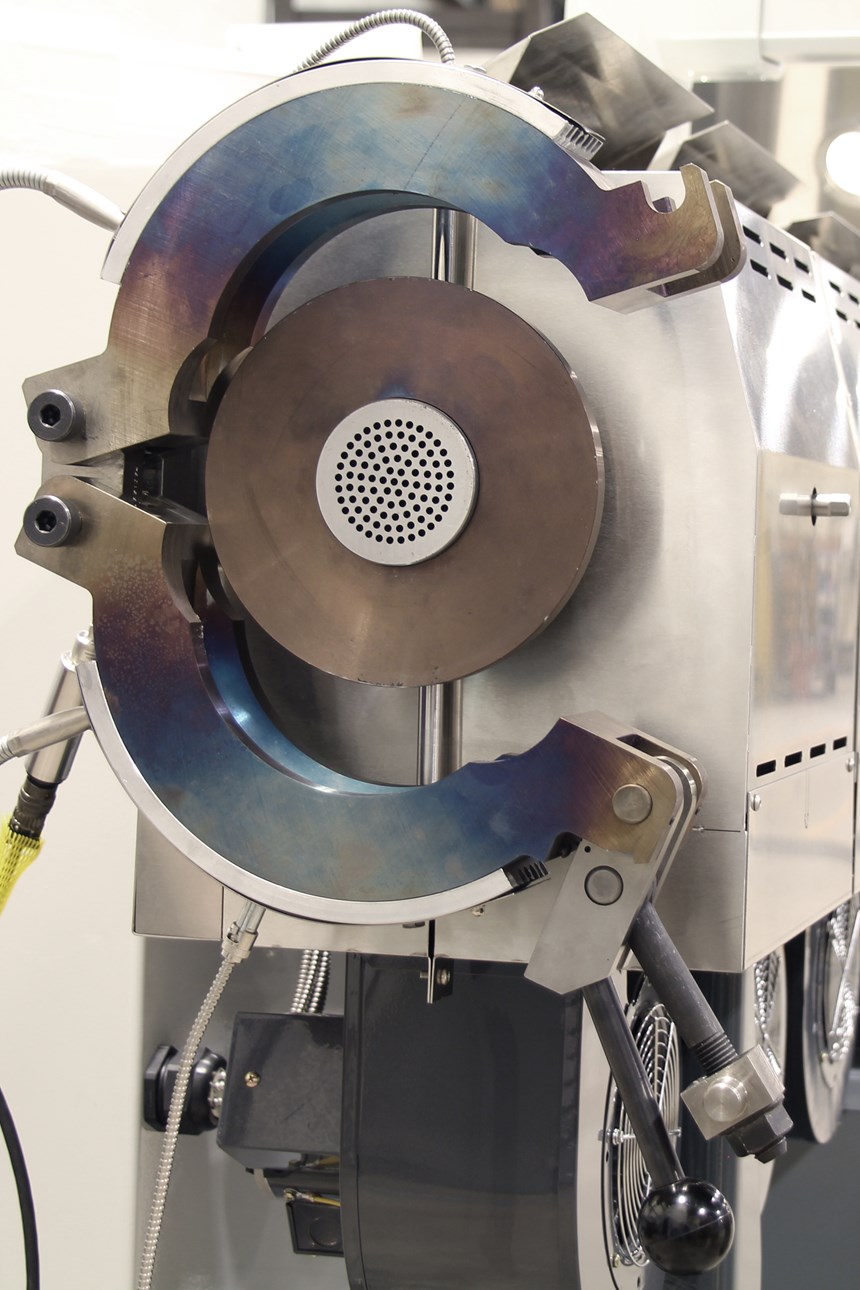

At its first-ever NPE, US Extruders is showing a new generation of highly engineered, custom single-screw extruders. On display will be 2.5-in., 24:1 and 3.5-in., 24:1 extruders, as well as a compact custom medical extruder. The 2.5-and 3.5-in. extruders feature a unique heater-shroud design made of individual stainless-steel shrouds that provide quick access to each zone. Dual-layer stainless steel keeps the exterior relatively cool to the touch. Thermocouples go through the side for easy replacement. Each shroud includes an adjustable exhaust deflector. Integral wireways are also built in to provide a clean look and easy access to wires.

The machines on display will also have a C-clamp with an easy-open, over-center lever and thumb-release safety lock. The lever-action swing bolt needs no wrench adjustment once the position is set. Durable aluminum heaters allow for consistent heating throughout clamp. A linkage counterbalances the two halves, so they open together. Moreover, on this extruder the motor is mounted on a pivoting base. This unusual design provides auto-adjusting tension on the V-belts. The motor mount’s pivot location is determined by the motor weight and torque reaction to constantly provide the correct tension. The feed throat is integral to the barrel with an air/water-cooled, jacketed feed area. The one-piece feed section eliminates alignment and step/mating issues that can be found in conventional cast-iron feed sections with bolt-on barrels. The bimetallic feed area provides maximum wear resistance.

The 2.5-in. model at the show will be equipped with ProControl Deluxe from ProSystems Integration. This is a comprehensive operator interface to control the entire process. It offers recipe management, data acquisition, reporting and alarm analytics. The 3.5-incher will be furnished with ProControl DCR, a cost-effective alternative to discrete controls. It includes basic extruder control along with recipe and alarm enhancements.

The compact custom medical extruder at the booth includes a servo drive, swappable barrels, washdown design, integrated control cabinet with special die-wiring management, and other special features designed for the medical and pharmaceutical industries. The machine has swappable barrels in 0.50-, 0.75-, and 1-in. sizes. This machine also has the medical version of ProControl touchscreen control.

New from Milacron Extrusion Technologies, the SV350 is billed as a robust and flexible extruder suited for processors of profile, tubing, sheet, fiber, wire and cable. The SV350 is available in sizes from 2 to 4.5 in. with 24:1 L/D. As a stock machine, it is available for quick delivery.

The solEX NG from Battenfeld-Cincinnati, is a single-screw extruder for high-performance applications that offers up to 20% higher outputs, up to 15% lower energy costs, and approximately 15-20° F lower melt temperatures, the machine builder says. Lower melt temperatures allow polyolefin pipe producers to either shorten the length of their downstream cooling system or maintain the same length to boost output by as much as 20%. Lower melt temperatures at a consistently high level of melt homogeneity also result in better product quality through reduced sagging, for example, which is particularly important for thick-walled or large-diameter pipes.

FILM & EXTRUSION COATING NEWS

At one time, many blown-film machinery suppliers ran full-production lines at NPE, much like they still do at the K Show. Nowadays, most NPE exhibitors have decided that’s no longer necessary. But NPE2018 will mark the third straight show that Macchi will buck the trend. The Italian machine builder (with U.S. offices in Dalton, Ga.) will run a five-layer POD (polyolefin-dedicated), high-output line producing PE film for stand-up pouches. During the five-day show, Macchi will demonstrate the line’s capabilities to downgauge by up to 30-40%.

In blown film, two issues are crucial: faster changeovers and higher throughputs. Concerning the former, Windmoeller & Hoelscher has made its TurboClean automation module retrofittable to some existing W&H lines. The TurboClean system purges resin from all extruders and gravimetric hoppers simultaneously, dramatically decreasing the time required to change materials. It was introduced at K 2015, at which time it was only available on new W&H Varex II systems. Now, existing W&H Varex II and Varex I lines built in or after 2010 can be retrofitted with the module, allowing blown film processors to benefit from significant cost savings from faster job changes. With TurboClean, material changes are almost completely automated. Operators no longer need to manually purge resin one extruder at a time. Instead, the work steps are automated and run simultaneously, requiring the operator only to change the suction wand from one resin port to the next.

Speaking of fast changeovers, Hosokawa Alpine American will be touting the benefits of its X die, billed as the fastest-purging die on the market. It is offered for up to 11 layers.

Also in blown film dies, Germany’s Kuhne Anlagenbau GmbH will be showing a concept Mo-Con die that is modular, streamlined, compact, and expandable.

The stackable Layer Sequence Alpha Dual Spiral Systems (LSADSS) blown-film dies from Alpha Marathon reportedly provide superior streamlining and mixing of melt flow as well as interlayer temperature isolation. The addition of the new patented Feed Block System allows film processors to extrude two different materials in the same module to either duplicate the number of layers or introduce new materials to the film structure.

On the matter of throughput—that other big issue in blown film—Addex Inc.is showcasing its latest Intensive Cooling technology at NPE2018. The company will launch its “Height-Adjustable” Intensive Cooling Twin-Stack system, which is designed to optimize performance when processing both high- and low-melt-strength resins.

Addex offers an enclosed, two-level, stacked, Intensive Cooling system featuring a lower cooling element that mounts flat against the die, and a second, height-adjustable cooling element just below the air ring. The system is highly adaptable to changes in materials and supports fast changeovers, Addex says.

The fully enclosed Intensive Cooling Twin-Stack elements can be separated by 1 to 16 in., allowing the operator to change the height between the cooling elements to control the amount of cooling. For super-low-melt-strength materials, a short distance between the elements is ideal. For high-melt-strength resins, the cooling zone can be extended to its maximum by the push of a button. The Height-Adjustable Twin-Stack system can be fine-tuned across a broad range of products without time-consuming equipment changes—and while the line is running.

The original fixed-height Twin-Stack system has proven in the field to increase output by 15% to 20% for very low-melt-strength materials, and up to 40% or even 50% for high-melt-strength materials. The Height-Adjustable version of the Twin-Stack is expected to produce even greater gains. The system operates over a wide range of configurations and materials, while also enhancing bubble stability. These retrofits are aimed at blown-film lines designed for higher outputs and with sufficient extruder and blower capacity to handle the output gains from the Intensive Cooling Twin-Stack.

Also in the area of blown-film cooling, Brampton Engineering announced the launch of the new Vector S air ring. Vector S offers an auto-gauge option utilizing segmented air. Thanks to extremely uniform airflow around the lip, Vector S reportedly offers the best startup gauge in the industry by reducing variability by up to 80% compared with conventional air rings. Vector S also boasts the highest resolution in the industry because it has 180 digital control points adjacent to the lip, vs. 60-80 in typical conventional air rings. Vector S is also said to be “smart”: It offers a digital setup memory and automated monitoring for repeatable quality.

Brampton has also announced that its pancake-style Streamlined Coextrusion Die (SCD) 4.0 will be available for retrofit on existing lines regardless of age, model and machinery manufacturer.

D.R. Joseph will be exhibiting a new control feature for non-IBC blown-film lines—neck-height control for medium- or high-stalk bubbles. It’s a new option on the company’s LF-Sizer product line, which manages layflat width for non-IBC blown film lines. The control system uses an ultrasonic sensor facing the bottom of the bubble flare to measure neck height, then maintains the setpoint to within ± 0.25 in. It also coordinates the competing tasks of managing layflat width and neck height during startup, hole recovery, and normal production. This coordination reduces time to production and improves production rate. Integration with the air-ring blower (varying blower speed to control neck height) is via standard serial data communication to a Yaskawa A1000, P1000 or V1000 inverter. The feature also includes an inverter programming function that reduces initial setup time.

Controlling and maintaining neck height on high-or medium-stalk bubbles correlates directly with improved consistency in HDPE/MDPE film dart-impact strength and other properties related to neck height. Other benefits processors can expect include increased production rate, tighter layflat control, and elimination of dart-impact failures.

D.R. Joseph will also be unveiling a new generation of radial roll cages that it says completely address the shortfalls of traditional radial sizing cages. Mechanical linkages and moving parts are greatly reduced, as is overall footprint (like iris-style cages), and the total investment cost is comparable to iris-sizing cages. The unit offers processors higher precision in diameter adjustment, complete stability and bubble support at all diameter ranges, extreme rigidity with zero play or backlash, and improved IBC control with the DRJ IBC control system. With axial-roller diameter adjustment, IBC sensors are always placed perfectly perpendicular to the film surface to ensure that ultrasonic signals are ideally sent and received.

The new radial cage maintains the same soft rollers as previously offered, plus protected ball bearings and a variety of roller styles and covers to accommodate any type of film surface and eliminate marks common with segmented fluoropolymer rollers.

New surface winders from Macro Engineering and Technology feature a face width of 69 in. and maximum roll diameter of 3.3 ft. They offer gap winding, reverse winding, zero-fold transfer, tapered pressure and tension control, shaft extraction, electrical shaft loading, and ability to handle a wide range of film thicknesses from 15 to 300 microns. The winder is said to be suitable for high-barrier coextrusion and lamination.

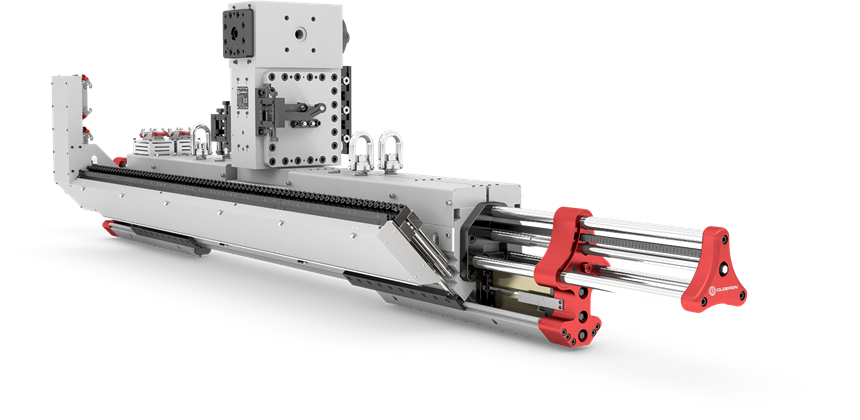

On the flat-film side of things, Cloeren Incorporated will be displaying the world’s widest nanolayer system, comprised of a 55-layer NanoLayer feedblock paired with a 5435-mm Epoch III die. This system is intended for third-generation (G3) nanolayer stretch films. According to Cloeren, nanolayer films have become a mainstay in cast stretch film because they offer enhanced performance in high-speed power pre-stretch applications. Second-generation nanolayer stretch films reportedly provide measurable reductions in shipping losses through their enhanced performance over conventional stretch films, and G3 films have been developed for further enhancements in packaging integrity.

Cloeren will also show for the first time the EBR V (edge-bead reduction) die for extrusion coating. This is the latest and most advanced design in its EBR series. Over the past five years Cloeren has installed more than 50 EBR V dies worldwide, and reports that the new design has reliably demonstrated increased operational robustness over any other edge-bead reduction die in the market. EBR dies are aimed at extrusion coating and lamination, which require great flexibility for frequent web-width and formulation changes. Being able to reliably minimize the volume of material at the edge bead with the EBR V deckle system has economic and environmental advantages, says Cloeren.

Cloeren will also show its moebius-manifold die. The innovative internal geometry of this die has proven to be particularly suited for processing polymers sensitive to residence time, including PVC.

SHEET EXTRUSION NEWS

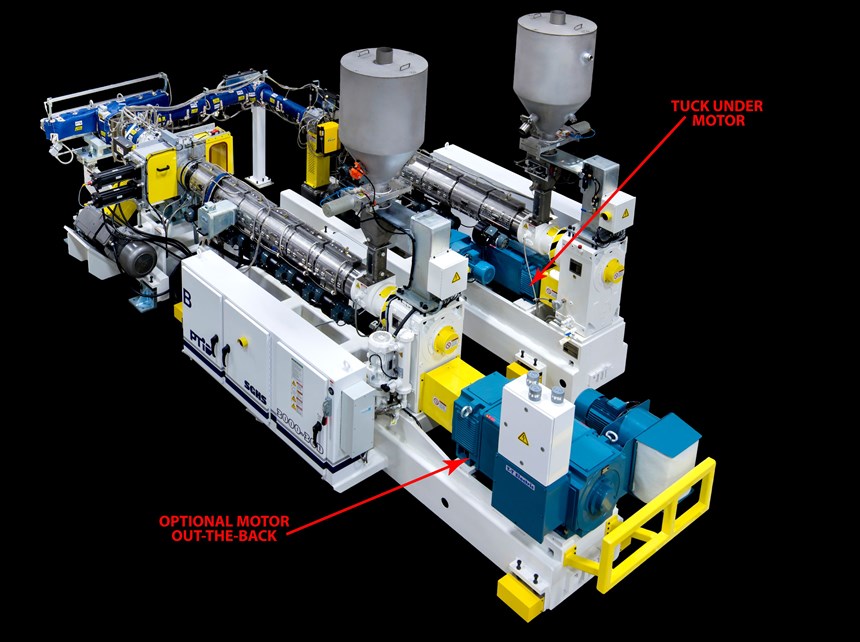

In sheet, machine builders at NPE2018 will be meeting the need for speed. Plus, the latest Super-G HighSPEED Extruders from Processing Technologies International (PTi) have a significantly reduced footprint, resulting in the highest extrusion output/ft2 in the industry, the company claims. This compactness is made possible by introducing an optional tuck-under motor on these models, which are used for processing PP and HIPS for packaging. Several machines have already been installed in the U.S.

PTi’s Super-G SGHS3000-36D model on display features a vertical U-configuration and tuck-under motor to reduce the machine’s footprint by more than 33% to 12 ft, 8 in., vs. 17 ft, 7 in. for the original model. The Super-G SGHS3000-42D model is also offered with the tuck-under option and shows a comparable footprint reduction and similar output gains.

The Super-G SGHS3000-36D has a 500-hp motor and runs at a maximum speed of 1000 rpm, while the Super-G SGHS3000-42D has a 600-hp motor and runs at up to 1200 rpm. For processing PP, the Super-G SGHS3000-36D has a production output of approximately 3000 lb/hr.

PTi entered the high-speed extruder segment with the launch of its Super-G High-Speed Extruders, which deliver significant performance advantages and overcome the limitations of competing machines. PTi’s high-speed solution reportedly delivers improved melt quality because of its Super-G Lobe screw technology and is offered integrated with all of its advanced G-Series Configurable roll stands. PTi’s high-speed extruders also feature carbide-lined barrels and Colmonoy hard-faced feed screws vs. case-hardened screws on competing models.

There is a new option for “no dry” PET sheet systems. The STARextruder series from Battenfeld-Cincinnati features a three-part processing unit: a single-screw zone for material plastication; a planetary-roller section for degassing under high vacuum; and an optimally dimensioned discharge zone. The planetary-roller degassing zone reportedly offers highly efficient degassing of the melt. The melt is rolled out in very thin layers, creating an extremely large surface area. Both effects are said to counteract degradation of the materials and significantly contribute to product quality.

Sheet processors can switch from PET to PP or PS processing on this extruder without a screw change. PET bottle flakes can be processed without pre-conditioning. The process has recently been issued a letter of non-objection by the FDA. The STARextruders are available in sizes of 3.5, 4.75 and 6 in., with output ranges from 1300 to 2600 lb/hr.

Gneuss Extrusion Technology is showing a complete Gneuss Processing Unit (GPU) comprised of a Multi Rotation System (MRS) 130 extruder, a fully automatic melt-filtration system (RSFgenius 150), and a VIS online viscometer. The line is made for processing undried, uncrystallized PET at up to 2000 lb/hr.

Gneuss now offers a new foam module that permits processors to quickly switch from solid to physically foamed PET sheet. Foam sheet with a weight reduction of 50% can be extruded (depending on the process) with a consistent cell structure and mechanical properties from up to 100% post-consumer material.

Graham will display a Welex Evolution sheet line, a complete production line for sheeting, winding, and in-line thermoforming, equipped with XSL Navigator control. While the equipment on display at NPE2018 will be for thin-gauge PP, the Evolution system can be customized for widths from 36 to 90 in., gauges from 0.008 to 0.125 in., and throughputs to 10,000 lb/ hr. Monolayer or coextrusion systems are available, with up to nine extruders.

PIPE, PROFILE, TUBING NEWS

The conEX NG from Battenfeld-Cincinnati is a conical twin-screw extruder for PVC pipe and profiles. The screw core fits all screw tempering systems, and the gearbox design allows several different motor positions (U or Z version). Processors can also choose between different barrel tempering and dosing systems, allowing a wide range of outputs to be covered with one machine. The machines can work with process pressures up to 520 bar (7500 psi), which are required when producing small or thin-walled profiles or when using regrind and recycled materials in coextrusion. Thanks to minimized residence times and quick cleaning, color changes can also be done much faster, which saves material, the company says.

Complete thermal insulation of the barrel minimizes radiation losses, and by using reluctance or synchronous motors, the conEX NG offers reported energy savings of up to 20%.

The conEX NG extruders are available in three sizes (42, 54 and 65 mm), with outputs from 80 to 550 lb/hr for profiles, and 100 to 1000 lb/hr for pipe. Several different space- saver or column designs are available for coextrusion. These can be adapted to every main extruder through improved height- and tilt-adjustment facilities.

KraussMaffei Berstorff is demonstrating its response to demands by processors for conical twin-screws that can be used both as main extruders and as part of a coextrusion system. The KMD 73 K/P conical twin at the show reportedly offers just that—high outputs and pressure stability in a robust machine design. The optional bimetallic barrel lining paired with a tungsten-carbide welded screw—a requirement of the North American market—also enables it to be used in pipe extrusion. Space-saving and customer-specific coextrusion models can also be installed in tight quarters for efficient production.

Downstream, the company will demonstrate its flexible calibration basket, the QuickSwitch system, which has an effective diameter range from 11.023 to 19.685 in. The system is of interest particularly to processors that run large pipe, because a diameter change is said to generate very little waste. All process parameters can be set and stored in the all-in-one control system.

KraussMaffei Berstorff’s KM-VT 250/1/6 vacuum tank for pipe extrusion features integrated vacuum control and frequency-controlled pumps that are fully integrated into the C6 line control system. This is said to provide for energy savings and uniform product quality.

Milacron will display its TC conical twin-screw extrusion system, which has a wide range of options and customized screw designs matched specifically to the process requirements.

Guill Tool & Engineering will show the latest generation of its Series 800 two- to six-layer extrusion tooling for tubing ODs from 1/8 to 6 in. Aimed at automotive, medical, appliance, and industrial applications, the redesigned Series 800 is said to produce flawlessly smooth extrusion and layer definition of tubes from fluoropolymers and other materials for multi-layer, multi-lumen medical tubing, as well as fuel-line constructions, multi-layer PEX pipe and drip-irrigation applications.

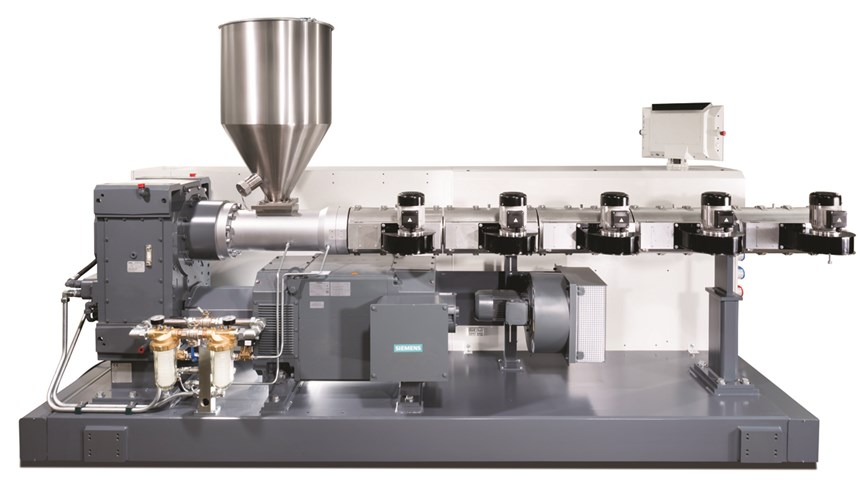

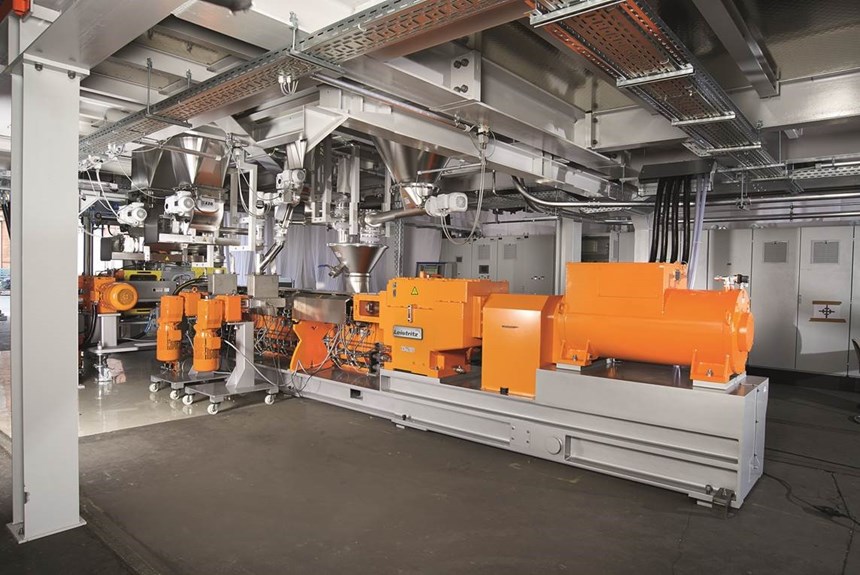

COMPOUNDING NEWS

Leistritz Extrusion will be displaying a range of new systems for compounding, including complete twin-screw extrusion lines. The ZSE 18 system on display will consist of loss-in-weight feeders, a co-rotating twin-screw extruder, gear pump, and die to produce 1- to 5-mm 3D-printing filaments. Downstream, the line is equipped with a custom air rack for air-quench cooling and sizing of the filament, plus a belt puller, laser gauge and winder. The control system will integrate closed-loop pressure control to ensure a tight-tolerance product.

With the ZSE 18 system, formulations can be modified “on the fly” for rapid sampling of filaments with different formulations. A sample can be produced every 10 min. The ZSE 18 system is rated to run at up to 797 F, suitable for high-temperature engineering polymers, and can run at rates from 2-44 lb/hr.

Leistritz is also displaying a ZSE 50 MAXX twin that includes modular barrels and screws and an insulated barrel cover. Extended length facilitates multiple downstream operations, including multi-stage venting, liquid injection, and up to two LSB 50 XX side stuffers for filler/fiber introduction into the melt stream. The ZSE 50 MAXX can be equipped with a 600-hp AC motor to produce more than 2200 lb/hr at 1200 rpm.

The LSB XX series side stuffer is supplied with a high OD/ID ratio of the screws (2.0:1) and can also convey materials with very low bulk densities. The screws can be segmented so they can be configured for a particular material. The LSB XX can be adapted to the processing unit via tierods. Its barrel can be jacketed for cooling or heating. Internal screw cooling is optional.

Leistritz will also show a ZSE 27 MAXX co-rotating twin-screw with an air-quench pelletizer. Various control architectures will be displayed, including Allen-Bradley and Siemens PLCs and operator interfaces. Both types are equipped with remote VPN accessibility for process analysis and troubleshooting. The company will also debut its Elongational Rheometer. This device mates to an extruder; a small amount of the melt flow is diverted, measured and returned to the extruder to facilitate on-line analysis and adjustment of shear and elongational viscosities.

ENTEK Extruders will be displaying two machines in its booth: a new QC3 33-mm twin-screw extruder, introduced in 2017 and being shown publicly for the first time; and a high-output 73-mm twin-screw. Entek is also featuring two interactive work stations showing the company’s screw-layout software.

The ENTEK QC3 33-mm co-rotating twin-screw is a new size. It’s designed for compounding small lots and includes all of the company’s latest QC3 (Quick-Change, Quick-Clean and Quality Control) features. The 33-mm unit joins ENTEK’s other QC3 models, which include 27-mm, 43-mm, and 53-mm co-rotating twins. New mechanical design features in the 33-mm model include self-aligning screw-gearbox couplings to facilitate fast and foolproof installation of screws; lock-and-key feature on splined shafts to prevent screw timing errors; conveniently located gauges for quick monitoring of lube and cooling-system conditions; quick-change strand die; and enhanced controls.

ENTEK will also feature a 73-mm twin geared for high-output custom compounding. It’s available with a 600-hp motor and screw speeds up to 900 rpm. ENTEK will have two interactive work stations at its booth where visitors will be encouraged to see how easy it is to quickly design screw and barrel layouts for their specific applications.

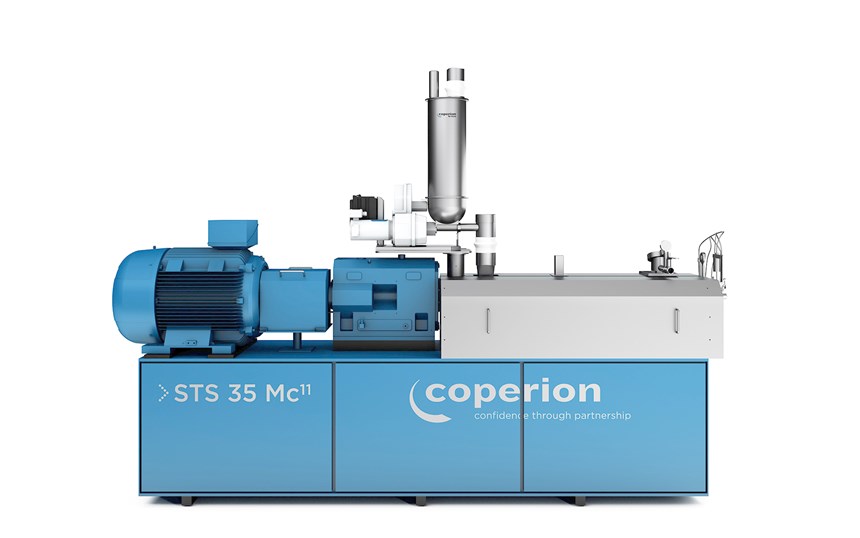

With color masterbatch in mind, Coperion Corp. has equipped its STS Mc11 twin-screw with features that significantly improve the system’s handling and ease of cleaning. A new base-frame design allows for integration of the water manifold and wiring connections for better cleanability without sacrificing accessibility.

Operations around the machine are reportedly simpler since Coperion reengineered the extruder covers to enable easy access to the process section and at the same time reduce dust contamination. The unit also includes a smoother surface for easier cleaning. The barrel heater shells are equipped with insulation plates to minimize the temperature on the surface of the process section. The barrel feed opening is fitted with a removable sleeve, which facilitates simple cleaning and therefore quicker color changes. A tray has been added to the vent port to collect drippings or vent flow. And the die head has been redesigned so it can now be quickly opened by simply loosening swing bolts for faster color changes.

The STS 35Mc11 exhibited at NPE2018 will be equipped with a Coperion K-Tron K2-MV-T35 volumetric twin-screw feeder—billed as an economical and reliable solution for metering color premix batches. The T35 feeder handles free-flowing to very poorly flowing powders (e.g., lumpy, moist or bridging materials) as well as fibers, flakes and other bulk materials. The T35 has interchangeable feeding tools and is easy to disassemble. All parts in contact with the raw material are stainless steel. A horizontal agitator gently moves the bulk material to the large feeder throat and then into the screws. The feeder comes with a Coperion K-Tron SmartConnex control system, which allows individual or multi-component control. Rate range (depending on material) is 0.04 to 88 ft3/hr.

Coperion will also display its ZRD rotary valve—now manufactured in the U.S. The valve is engineered for heavy-duty industrial service with pressure differentials up to 21 psig and temperatures up to 212 F; higher temperature options are available. The ZRD is often used as a discharging and metering valve for conveying products in powder and granular form.

Coperion will be showing a mechanical bulk-material mixer called Mix-A-Lot. The unit reportedly provides efficient, high-speed, and gentle homogenization. It’s available in three sizes for throughputs up to 5 tons/hr. The surface of the mixing chamber can be electro polished.

The combination of an outstanding mixing effect and extremely short mixing time is due to the optimized design of the mixing rotor, Coperion says. Its low circumferential velocities and the optimum design of the gap to the housing permit gentle handling without particle destruction or heating of the product. The large inspection door on the front of the mixer provides easy access to the entire process chamber. An additional opening at the discharge flap also facilitates inspection and cleaning of this section.

Up to now, it has generally been standard practice to feed each individual component to the extruder through a separate differential loss-in-weight feeder with a buffer hopper. However, the new Mix-A-Lot first produces the specific pellet mixture, for which one single loss-in-weight feeder is then sufficient. The weighing function of the mixer ensures accurate recording of the weight of each component, to guarantee correct dosing according to the recipe. As the Mix-A-Lot is vacuum and pressure resistant, direct pneumatic feeding is possible without the need for a separate reception bin for pneumatic conveying. This simplified concept reportedly allows reduction of investment and maintenance costs. Cleaning effort during product changes has been greatly reduced, and much less space is required above the extruder.

Nordson Corp.’s new pellet dryer—for use with its BKG pelletizing systems—reportedly meets the challenge posed by the steady growth in use of glass-filled and other abrasive materials by substantially reducing the time and cost associated with replacing wear parts. The design reduces the number, complexity, and cost of dryer components that are subject to abrasion and makes them more accessible for maintenance or replacement. The new design reduces production downtime by simplifying maintenance.

MELT FILTRATION & PUMP NEWS

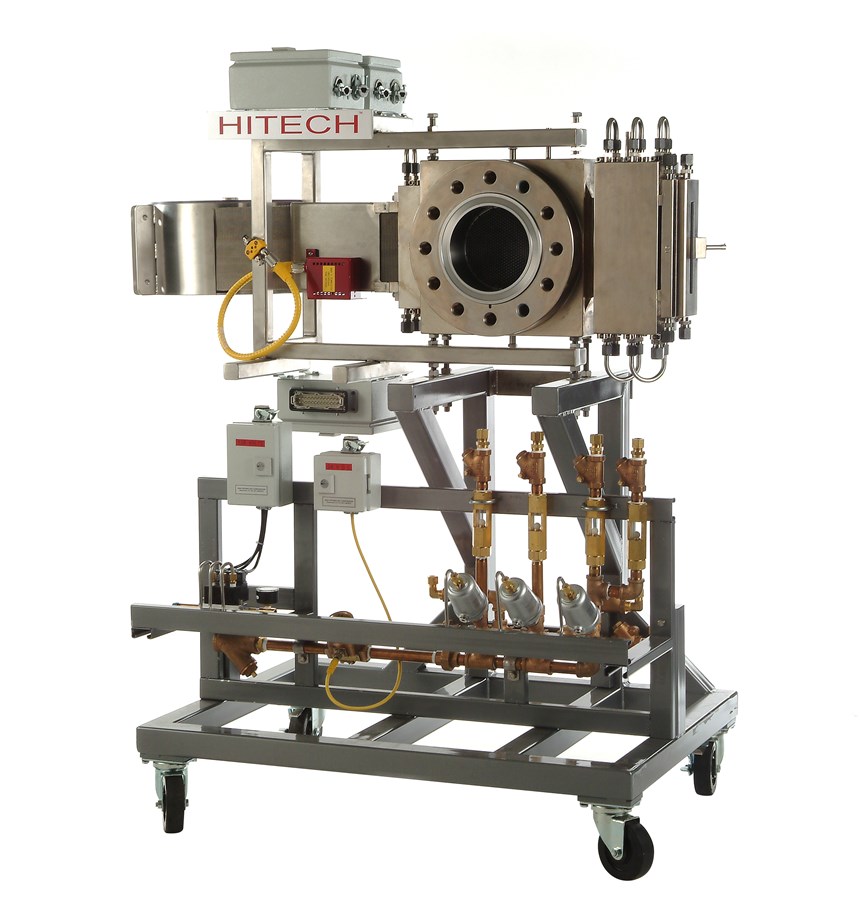

High-Technology Corp. will be introducing its next-generation Model DP-XL fully automatic screen changers. They feature significantly enhanced performance and ease of use for a variety of applications. The DP-XL can advance the filter screen at twice the rate of previous models, thereby allowing filtration of higher percentages of contamination than previously possible. The new design is capable of leak-free processing up to 650 F and generates a polymer seal that results in smooth, uninterrupted screen advancement cycles.

In addition, new high-strength filter media enable the unit to operate reliably even under constant differential pressure across the screen of up to 2000 psi. Multilayer filter-media combinations can filter down to 50 microns for a wide range of polymers, both high and low viscosity.

PLC color touchscreen controls and descriptive graphics allow for full custom integration of the screen changer into the most complex lines. Both operating parameters and hardware conditions (such as heaters and sensors) are continuously monitored, enabling fast response. The controls, including 20 discrete alarms, detect real-time processing conditions and automatically adjust the rate of screen advancement, at intervals from 5 min to 8 hr, to maintain the highest degree of continuous production, even with uneven levels of contamination.

The ILF-55 in-line filtration system from PSI-Polymer Systems is a discontinuous, high-capacity filter that is aimed at long production runs where the extrusion process cannot be disturbed and where ultra-high filtration levels must be continuously maintained. ILF filters are typically used where screen changers are either too large for the application or otherwise cannot satisfy the filtration requirement without incurring an unacceptable pressure drop.

These new filtration systems feature a canister housing into which the filter pod assemblies are inserted. Vessel size and filtration media are selected according to application-specific data and are designed to minimize pressure drop for optimal flow and run time.

ILF vessels with three or seven filter tubes can be fixed in-line or can be interchangeable. The interchangeable vessel option accommodates quick changeouts. Standby vessels can be preheated to minimize downtime. Vessels can be arranged for electric heat or jacketed for steam/oil heating.

Filter tubes offer micron ratings from 0.5 to 250 and can be reusable (pleated filters) or single-life (slip-on wire-cloth tubes). All pleated filters are bubble tested for pore-size verification. All models are designed for operating pressure up to 4500 psi and process temperatures to 750 F.

Gneuss Filtration Technology is exhibiting several different models of its patented rotary filtration systems. Their screen cavities are arranged in a ring pattern encapsulated by two filter blocks. Screens can be inserted into the cavities by opening a small hatch-door without interrupting production.

Modifications to the screen-changer housings permit operation on a wider range of applications at higher pressures, while offering larger active filtration areas. Components and modules have been standardized to offer shorter delivery lead times and lower costs.

The SFXmagnus series operates automatically and keeps process and pressure constant. The series is characterized by an extra-large active screen area, compact design, and easy operation. Screen changes reportedly do not affect product quality. An SFXmagnus 60 with an active filtration area of 23 in.2 will be displayed.

Gneuss’ top-end model, the RSFgenius, will also be on display. It operates with an integrated self-cleaning system for very demanding applications and highest quality requirements. Screens can be automatically reused up to 400 times; filtration fineness below 10 microns is available.

Gneuss will also be exhibiting a KF 150 screen changer with an active screen area of 28 in.2. The KF range of continuous filtration systems is designed specifically for applications with frequent material or color changes, as well as for high-pressure applications like blown film. The KF screen changers are said to be very compact and to permit simple and quick screen changes on the fly.

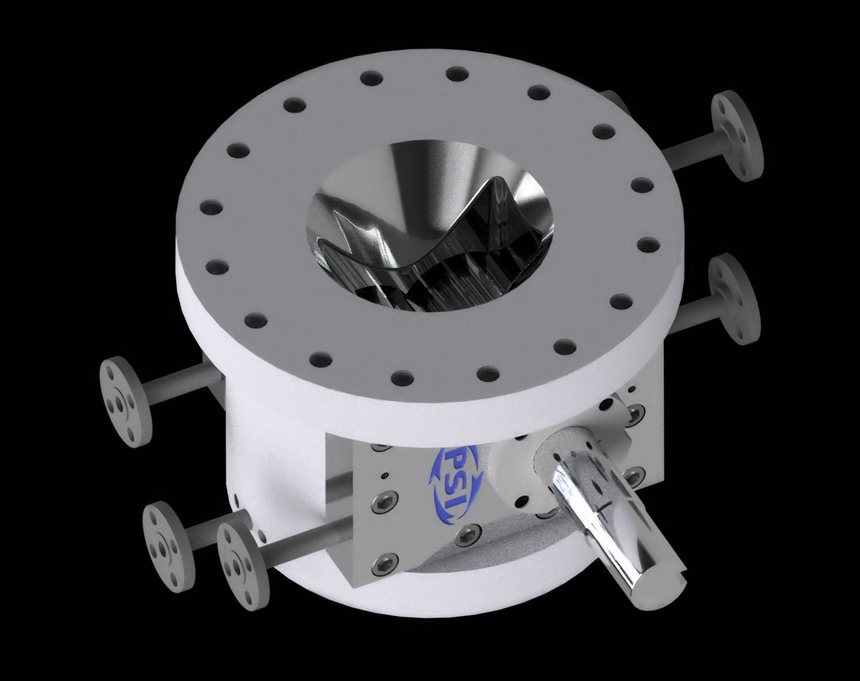

In melt pumps, PSI-Polymer Systems will introduce its first Vessel Gear Pump (VGP). This product is used beneath polymer reactor/devolatilization vessels or after large twin-screw compounding extruders for discharging a steady volumetric output direct to the pelletizer. The VGP series accommodates pilot operations to full production up to 20,000 lb/hr.

These high-efficiency pumps generate high discharge pressures while accommodating very low-pressure infeed of high-and low-viscosity materials. Typical inlet pressures are under vacuum or up to 145 psi. A choice of feed openings optimizes flow even under conditions of very low vessel fill levels and high vacuum. For higher viscosities, to avoid cavitation and ensure positive fill of the gear teeth, PSI offers 170° of gear opening.

The new VGP features a small footprint and all stainless-steel construction. Housings (forged or cast) contain internal flow passages for steam or oil heating. Models accommodate discharge pressures to 4350 psi and a temperature range to 500 F with an option for 660 F.

Shaft sealing is accomplished using single or double mechanical seals or standard visco seals. Seal design accommodates fast, easy replacement, with off-the-shelf seal availability from PSI. The company says this is an important feature, as a common problem with these types of products is availability of replacement seals.

Related Content

Medical Tubing: Use Simulation to Troubleshoot, Optimize Processing & Dies

Extrusion simulations can be useful in anticipating issues and running “what-if” scenarios to size extruders and design dies for extrusion projects. It should be used at early stages of any project to avoid trial and error and remaking tooling.

Read MoreWhy Are There No 'Universal' Screws for All Polymers?

There’s a simple answer: Because all plastics are not the same.

Read MoreTroubleshooting Flow Surging in Single-Screw Extruders

Surging can cause lower production rates, higher scrap rates, material degradation and higher labor costs. Here is a guide to troubleshooting this problem.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More