For Best Results in Plastic Color Control – Plan Accordingly

Sponsored ContentFrom the formulation of color in the lab to the quality control checks on the floor, using the right process and equipment is key to color matching from start to beautiful finish.

Color consistency in plastics is one of the key elements that determines production success or failure.

In the manufacturing of plastic products, the path from design to completion is made up of a series of touch points before a product reaches its final destination. Moving from the initial formulation of color in the lab to quality control checks on the production floor leaves a number of opportunities for an originally created product to end up looking as unrecognizable as a childhood acquaintance who shows up on your doorstep after twenty years. Or the variation may be less dramatic, yet still off by a shade or two. On either end of the spectrum, color consistency in plastics is one of the key elements that determines production success or failure.

A Few Colorful Examples

How many shades of orange are traffic cones all over the world? You can see them in your mind, that vivid hue you never mistake for peach or pumpkin. It’s the same traffic cone color everywhere, making it easily recognizable. In this case, the continuity, or “brand” recognition is vital to saving lives. But color precision is equally important to every brand for their survival. The yellow mustard of that squeeze bottle, the dark emerald green of a popular sparkling water; what if you told a kid to attach the blue block to the pink one and the box was filled with all different values of both those colors? The point is, it’s important to avoid the pitfalls of color control, and there are distinct places in the process where a color can quickly turn indistinct without proper knowledge and preparation.

In The Beginning

A product as presented by its originator is approved and the color then established as “the color” of that product. Then how is that color documented and duplicated exactly over and over again? In the instance of color matching, man proves most efficient when applying non-subjective instruments to his measurements.

It Pays to Share

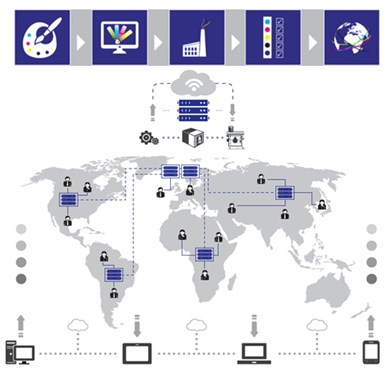

Consider an entire supply chain having the ability to access and share color measurement data and color standards/specifications anywhere, anytime—in real time.

Colibri® users have fast, secure and managed access to shared data from a central database and benefit from improved color communication.

With the implementation of a color management platform, your network has shared access to accurate data without delay. Efficiency and productivity are instantly elevated, transforming the global color process from a complex supply chain web to a more simplified, visible global network. From design to manufacturing to finished product, the employment of a fully integratable solution paves the way for optimized results with less waste, time and effort.

The Need for Continuity

As manufacturing a product includes many stages that demand the involvement of multiple departments, facilities, and suppliers, maintaining standards can be a challenge. As a supply chain grows, the process becomes even more complex and the need for seamless communication heightens. High accuracy, real-time data is key for communicating and meeting brand and product color specifications. The solution comes in the form of an innovative, more than welcome, centralized platform.

The Application of a Centralized Platform for Greater Color Control Efficiency

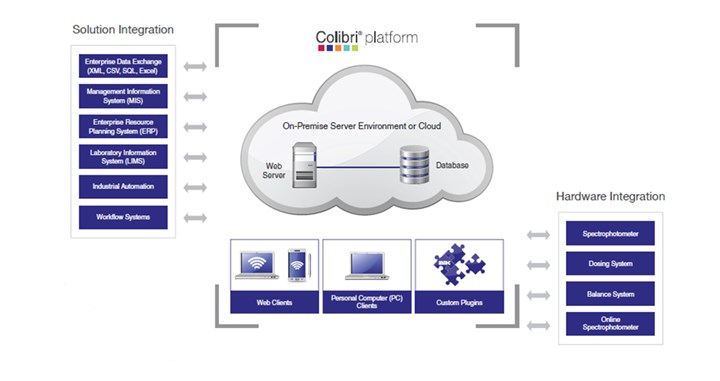

The Colibri® platform helps to specify, manage, formulate, produce and communicate colour throughout all stages of the supply chain.

Colibri Software® provides a single, organized database to manage color palettes, store color specifications and color values of samples, and access data generated internally and from suppliers around the globe. When combined with high accuracy color measurement instrumentation, the coordination of brand and product colors is seamless from beginning to end.

Brand owners and manufacturers use this technology to:

- Gain Complete Visibility across the Global Supply Chain: Access and share real-time color measurement data and color standards/specifications anywhere, anytime to ensure each department, facility, and supplier are meeting standards

- Optimize Management of Color Palettes: Store color standards/specifications in one central database for improved organization and management of color palettes and data

- Shorten Time to Market: Shorten the time of waiting for physically shipped data to arrive at every phase of development to zero—with a centralized platform, color standards and measurement data are just a key stroke away, available for instant access as each phase of testing is handed off to the next

- Minimize Errors and Waste: Identify inconsistencies in real-time, enabling users to make faster, more informed decisions and take corrective action immediately for improved productivity and output and to prevent future rejects and waste

- Reduce Operational Costs: Correct inconsistencies that lead to product rejection and waste; leave unnecessary shipping costs and overdue delivery to market behind with the implementation of forward-thinking technology designed explicitly for saving time and expense

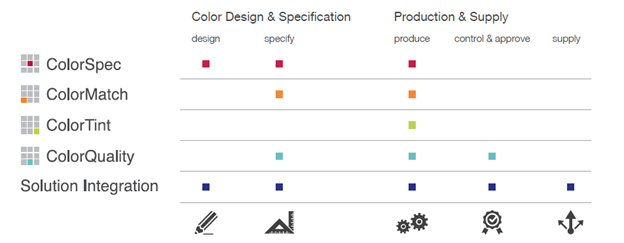

Powerful and easy to use, another benefit of Colibri Software® is that it can be hosted in any network or IT environment. And it can handle all color control intervals from specification to formulation all the way through QC using these state-of-the-art packages:

These packages add to the reason Colibri® is such a highly recommended platform across the board, for large global enterprises as well as single-client and small businesses.

Colibri Software Packages

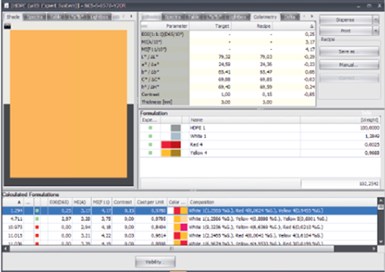

ColorMatch: For recipe prediction of color and opacity in different applications and on a variety of substrates. Uses a proprietary algorithm, ensuring accurate matching of color and opacity of opaque, translucent and transparent colors, while reducing the number of correction steps.

-

Expert - Versatile package allows you to define individual properties of the ingredients as base for the right pigment selection during recipe calculation.

The ColorMatch module ensures accurate matching of color and opacity of opaque, translucent and transparent colors, while reducing the number of correction steps to save waste and time.

- ColorantsetManager feature stores and updates colorant data, calibration data and optical data for use in recipe prediction and correction.

- BatchCalculator feature holds recipes for a large number of standards or entire color catalogue or using predefined Product Templates.

- Standard – Corresponds to Expert but does not contain the BatchCalculator feature.

- Light – Corresponds to Standard but does not include the ColorantsetManager. Can be used with a Colibri® Colorantset delivered by a colorant supplier.

- Basic - For customers with limited requirements or seldom use of recipe calculation or correction, the ColorMatch Basic with reduced functionality can be an affordable alternative to ColorMatch Standard.

All Products for ColorMatch include Quality Control and Tinting functionality, as well as the 3D Gamut Viewer allowing users to compare color collections and to discover gaps in the color space.

ColorQuality: For monitoring, certification and final approval of colored products. Organize quality control tasks, regardless of application or requirement. QC templates can be created with predefined settings to simplify workflows and prevent mistakes.

- Standard - Job displays and job reports can be customized to meet all monitoring and reporting requirements.

- Basic – Base features intended only for small businesses with limited quality control needs.

ColorTint: For dispensing of color recipes in Lab, manufacturing site or at the P.O.S. Intended use to be in tandem with ColorMatch. Having access to recipes in a central database offers time savings as data are available instantly for dispensing in production or at the POS.

ColorSpec: For the specification of brands, designs and standards. ColorSpec features are an integral part of all ColorMatch and ColorQuality packages but can also be beneficial as an additional or separate package if managing standards has a high priority. Users can define color standards, dependent standards and related tolerances for their products and communicate these brands, designs and standards to their suppliers.

Colibri® ColorSpec assists with managing a complete color pallet. From specification of color standards to the development and digital compliance criteria and eventually individual supplier review.

A Perfect Pairing

Another reason Colibri® Software is so widely used is its compatibility with a wide variety of Konica Minolta Sensing’s benchtop and handheld spectrophotometers. Colibri® software, designed to be used in conjunction with Konica Minolta’s high accuracy instrumentation ensures a finished product will meet its prescribed color standard.

While software programs such as Colibri® allow users to record, analyze and access measurement data anywhere, anytime, spectrophotometers quantify the color and appearance of an object to evaluate its color attributes and identify inconsistencies. From design to finished product, this standard method allows seamless communication and coordination because color values and data can easily be shared and accurately expressed to others.

Instruments for Various Application

Konica Minolta Sensing’s catalog of color measurement equipment is comprised of instruments created for the precise measurement of various, and even in some cases, specific substances at every stage and in every place measurement information is needed. Bench-top as well as portable and hand-held instruments facilitate the color continuity control process from origination to QC on the production floor. For measuring plastic color there are spectrophotometers that cover a multitude of applications.

New Spectrophotometers from Konica Minolta

Spectrophotometer CM-36dG — High-Precision Benchtop Spectrophotometer with Integrated ISO Compliant Gloss Sensor and Stability Check

Streamline your quality control workflow, reduce operator errors, and save on equipment and maintenance costs with the CM-36dG.

Spectrophotometer CM-36dG is the industry’s first color and gloss bench-top spectrophotometer, with an integrated ISO 2813 compliant 60° gloss sensor that measures color and true gloss simultaneously. The high-precision, high reliability instrument able to measure color in reflection or transmittance is ideally suited to a wide range of applications, including plastics.

Measuring and reporting color and gloss together in a single instrument, the CM-36dG streamlines your quality control workflow, reduces operator errors, and saves on equipment and maintenance costs.

CM-26dG Spectrophotometer—The Next Generation of Portable Sphere Spectrophotometers

The CM-26dG portable spectrophotometer offers unprecedented accuracy/inter-instrument agreement (IIA), usually reserved for laboratory-grade instrumentation. This precision will allow superior color communication throughout the supply chain

The CM-26dG spectrophotometer, like the benchtop CM-36dg, features an integrated 60-degree gloss sensor that allows for distinct color and appearance measurements within one instrument. Used for high-precision color and gloss measurement of smooth or textured samples, its horizontal alignment makes it a particularly convenient instrument to have—especially for accessing narrow spaces.

The lightweight ergonomic design also makes the CM-26dg easy to operate for both right or left-handed users. With optional Bluetooth™ and high-resolution TFT color display, the CM-26dG spectrophotometer is perfectly suited for applications in the field.

Learn more about the CM-36dg, CM-26dG and all Konica Minolta Sensing’s advanced color measurement devices and specifications by sensing.konicaminolta.us/us/

The Right Steps Toward Perfect Color

For the best possible color control all the way down the line, Konica Minolta Sensing’s Colibri® Software, working in tandem with the right measuring instrument, provides all the support needed to take the right steps toward perfect color—without the missteps.

From small mustard and water bottles to medium sized traffic cones and the largest of items, there’s a Konica Minolta solution to meet your needs.