Imagine A World Where Polymers Were First

One reason for the disproportionate attention that plastics receive in the environmental conversation is that they are newcomers. Perhaps if we had been relying on them for thousands of years, we’d view them differently.

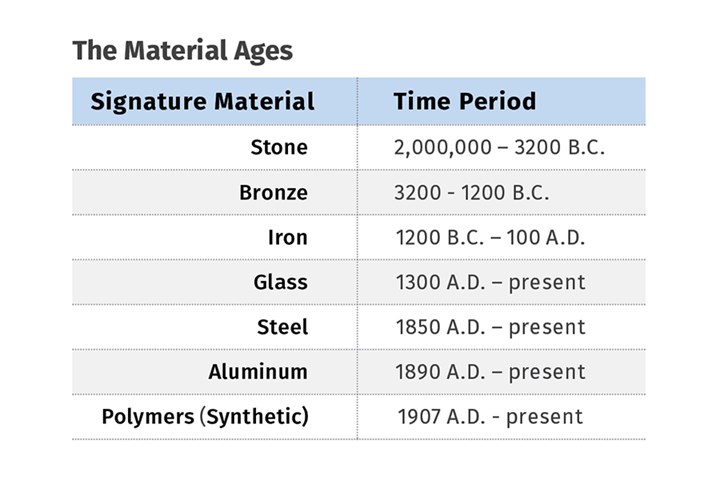

One way of documenting the history of the progress of civilization is by chronicling the development of the materials that are central to the technology of those civilizations. According to this scheme, the progress from the dawn of human presence on the planet can be traced through the stages summarized in the accompanying table.

This table contains some oversimplifications. With the exception of stone, all of these materials involve the need for the development of technology to isolate these materials and fabricate articles from them. Consequently, the development of any of these materials during the stated time intervals was preceded by prolonged processes of accidental progress.

Iron, glass and steel were known for hundred or even thousands of years before the systematic technology needed to exploit these materials was developed. Aluminum is the most plentiful metallic material in the earth’s crust, but accessing it economically was not possible until Austrian chemist Carl Joseph Bayer developed the process for purifying bauxite and the Hall-Heroult process was created for smelting the resulting alumina.

And as we know from our recently completed review of the history of polymers, the development of the first truly synthetic polymer (phenolic) was preceded by over 80 years of experimentation with natural materials.

This table makes it very evident that synthetic polymers are the new kids on the block. This may account for the disproportionate amount of attention plastics get when the environmental impact of manufactured materials is discussed. But imagine for a moment an alternate universe where, after the use of stone, polymers were first. Consider a world where sometime near the dawn of Egyptian and Sumerian civilization, the first materials created from natural resources were lightweight, ductile, corrosion-resistant and, in some cases, transparent.

Moreover, forming of these raw materials into the associated products could be performed at temperatures somewhere between 100-400oC (212-752oF). Then, consider further that after a period of time comparable to the Bronze Age, about 2,000 years, the next new thing was brought to market.

Conceivably, a large amount of pollution composed of denser materials can collect on our ocean floors, unnoticed and very challenging to recover.

Whether the next development would be metallic or ceramic (glass), the processing temperatures associated with these materials are not hundreds but thousands of degrees. So, the energy consumption associated with making any of these materials and then fabricating products from them would be much higher than that associated with working with polymers. The equipment needed to house these processes would also need to look very different.

Glass vs. APET

Take glass as a comparison with what would have been the incumbent materials, which likely would have been acrylic, PC or amorphous PET. The new material would require processing temperatures of about 1,400oC (2,550oF) as opposed to temperatures of 200-300oC (392-572oF) needed to process the transparent polymers. The new material, when formed into a bottle, would be many times thicker than the polymer bottle that was already in use. It would also be much heavier. Even the same volume of the new material would weigh twice that of the polymers that would have currently been in use.

And when one of these containers was dropped, rather than bouncing on the floor or developing a noncatastrophic crack or fissure, it would shatter into many small, sharp fragments that could cause injuries and introduce dangerous shards of the material into the surrounding environment. Who would be likely to embrace this new material?

Now let us turn our attention to the metallic materials. As with glass, processing most of these materials require temperatures in the range of 750 – 1,250oC (1382-2282oF). Forming can be done by a number of techniques which include casting, stamping and welding. Casting is done at the aforementioned high temperatures in facilities that have open furnaces of the glowing hot metal. Stamping must be performed in huge presses that are loud and produce sharp edges on the work pieces that must be deburred in a secondary operation. Welding requires heating the materials to these same high temperatures using combustible gases. While some metals such as gold, copper, zinc and brass can be cold welded, the pressures required are extremely high.

Undeniably, structures produced from these metallic materials have greater strength and heat resistance than polymers. In fact, the development of these materials would enable types of polymer processing that would not have been possible without them. It is evident the development of metals — which in our fanciful alternate universe would have happened after the creation of polymers — would have expanded the options for melt processing of polymers to realms where high pressures and precise forming were required. These would include injection molding.

Metallics: Higher Density, Susceptible to Corrosion

But the downsides of the metallic materials would still be considerable. Among these are the higher density. Even the lightest of structural metals is 50% denser than most unfilled polymers, and the workhorse materials like iron and steel have densities 5-6 times greater. And metals are susceptible to their own brand of oxidative degradation known as corrosion. In contact with a wide variety of materials, including water and acidic compounds, corrosion becomes a significant concern that reduces the performance of the material. The extensive literature on the study of corrosion is evidence for the level of concern this mechanism presents.

Ironically, this higher density hides an environmental problem that receives a lot of attention these days: the islands of plastic waste floating in our oceans. This is a huge substantive problem as well as a public relations headache for the plastic industry. But one could make the case that at least the polymer contamination floats while other materials of higher densities that also contribute to the stress we put on the environment do not. Conceivably, a large amount of pollution composed of denser materials can collect on our ocean floors, unnoticed and very challenging to recover.

So, as we tackle the real issue of how to better preserve our world, we need to understand that all waste is problematic. Plastics get a lot of the attention because the volume is great and the material tends to show up in obnoxious fashion, like the plastic bags caught in a bush along the highway. But it seems likely that one reason for the disproportionate attention that plastics receive in the conversation is the fact that these materials are the newcomers. Perhaps if we had been relying on them for thousands of years, we would view them differently in the hierarchy.

ABOUT THE AUTHOR: Michael Sepe is an independent materials and processing consultant based in Sedona, Arizona, with clients throughout North America, Europe and Asia. He has more than 45 years of experience in the plastics industry and assists clients with material selection, designing for manufacturability, process optimization, troubleshooting and failure analysis. Contact: (928) 203-0408 • mike@thematerialanalyst.com

Related Content

How to Get Rid of Bubbles in Injection Molding

First find out if they are the result of trapped gas or a vacuum void. Then follow these steps to get rid of them.

Read MoreDensity & Molecular Weight in Polyethylene

This so-called 'commodity' material is actually quite complex, making selecting the right type a challenge.

Read MoreHow to Set Barrel Zone Temps in Injection Molding

Start by picking a target melt temperature, and double-check data sheets for the resin supplier’s recommendations. Now for the rest...

Read MoreTunnel Gates for Mold Designers, Part 1

Of all the gate types, tunnel gates are the most misunderstood. Here’s what you need to know to choose the best design for your application.

Read MoreRead Next

Processor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read More.jpg;width=70;height=70;mode=crop)