Leverage Your Cooling Power

You can predict the amount of heat you'll need to remove from parts before ejection with reasonable accuracy if you know polymer thermal properties and certain other rules of thumb.

Injection molding is fundamentally a process that involves moving heat energy from place to place. After hot plastic is injected into the mold a certain percentage of that energy (heat) must be removed before the parts can be ejected. Knowledge of polymer thermal properties and rules of thumb allow us to predict the amount of heat that must be removed from the parts before ejection with reasonable accuracy.

We can think of the energy needed to cool the mold and parts as “Cooling Power” (CP). Mathematically speaking, it is simply

CP = ΔT x Q x C

where ΔT is the change in coolant temperature flowing through a cooling circuit, Q is the flow rate, and C is the heat capacity of the coolant.

Without worrying about the details of the math, we can readily see that Cooling Power costs money. There is the cost to control the cooling-water temperature, the cost of pumping it, the cost of a water-treatment plan, maintenance costs, and of course the capital cost of all the equipment and plumbing.

Sometimes, Cooling Power is a scarce resource. The classic example is adding more molding presses and plumbing, but no additional pumping or cooling capacity.

With these facts in mind it is reasonable to suggest that Cooling Power is a resource worthy of conservation, just the same as resin, colorant, packaging, and the like. In this article we will offer some ideas how to stretch your Cooling Power and add to your bottom line.

Recalling the expression CP = ΔT x Q x C, we can examine each variable to see how we might save energy:

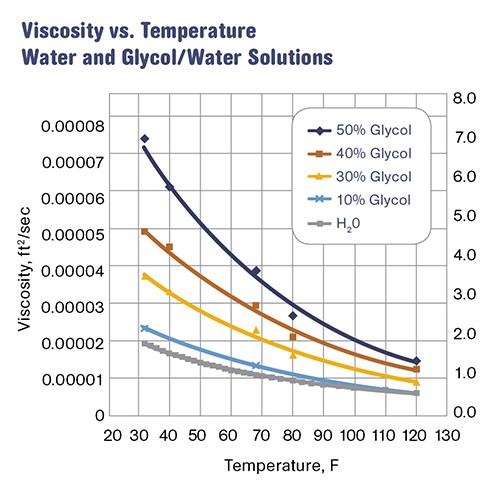

1. C is the heat capacity of the coolant. For water, this value is 1 Btu/lb-°F. We don’t have a good way to make this value higher, but we can try to do no harm. For example, molders sometimes use glycol-based antifreeze in solution with water to allow lower chiller setpoints and a colder mold. Adding glycol to water decreases the heat capacity and increases the viscosity of the coolant. The greater the percentage of glycol, the greater the effect. These effects result in increased pumping cost compared with water. Additionally, higher flow rates are required to achieve turbulence, possibly taxing available pumping capacity.

In some cases, a colder mold works against part quality requirements such as surface finish, warpage control, and development of crystalline structures. Molders should carefully examine the economics of using glycol-water solutions and very low mold temperatures, as is discussed further below.

2. ΔT is the change in coolant temperature as it flows through a circuit. The temperature increase is influenced by several factors. Heat input from the shot, diameter and length of the circuit, circuit placement and condition, mold materials, and coolant flow rate all play a part.

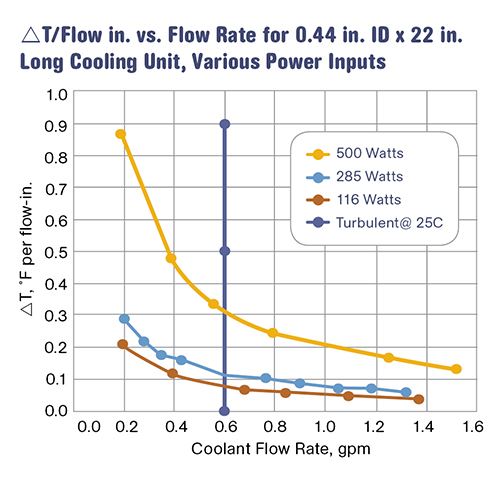

It is generally true that turbulent coolant flow results in relatively low values of ΔT in mold-cooling circuits. Figure 1 shows values of ΔT per inch of circuit length vs. flow rate at three different heat input values. Heat input corresponds to shot size.

In Fig. 1, ΔT is shown for a 7/16-in. (0.44-in.) diam. x 22-in.-long circuit with flow of 1 gpm and three relatively small shot sizes (such as for small parts in an eight-cavity mold). The values of ΔT for these shot sizes would be only 1.1-4.4° F. If we could make the circuit longer we could squeeze more Cooling Power from every gpm of coolant flow. But how can we stretch a cooling circuit?

We can nearly double the circuit length by looping a pair of similar cooling circuits together. In fact, you might loop more than two as long as it doesn’t cause excess mold-temperature variation or too much pressure drop and flow reduction. Avoid looping restrictive circuits with free-flowing ones, because the restrictive circuit will control the flow rate. The takeaway: Don’t be afraid to experiment with circuit looping. Carefully applied, it can multiply your Cooling Power.

3. Q is the coolant flow rate in a circuit. It is well known that turbulent flow increases the effectiveness of heat transfer in a cooling circuit and is an important factor in achieving efficient cooling. Turbulent flow depends on circuit diameter, coolant flow rate, and coolant temperature (viscosity). Turbulence can be predicted using available flow-measuring tools and published charts. As flow is increased beyond the turbulent transition, the potential heat-removal rate continues to increase but there is a point of diminishing return.

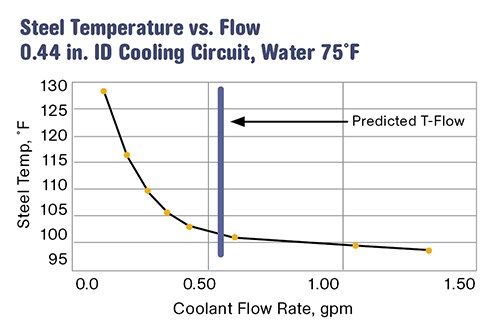

Our studies show that if cooling circuits are properly sized, increasing coolant flow to more than 1½-2 times the turbulent rate yields very little additional reduction in steel temperatures, (Fig. 2). Excess flow is costly since flow-related pressure losses increase with the square of flow rate. These facts can help you develop an efficient cooling setup and avoid excessive flow rates and wasted Cooling Power.

A final topic to discuss in the context of Cooling Power is mold temperature. One might assume that colder coolant is automatically better. Here are some reasons that might not be true:

•Lower temperature results in higher coolant viscosity, whether it is water or a glycol-water solution. At a temperature of 40 F a 10% glycol solution requires around 20% more flow to achieve the same cooling capacity as water alone. Increasing the antifreeze concentration to 20% requires about double the flow. Figure 3 illustrates the effects of various concentrations of glycol and reduced coolant temperature on viscosity.

•Increased flow uses more pumping capacity and causes higher pressure losses throughout the piping system and molds. Pumping horsepower requirements increase by the square of flow-induced pressure loss.

•Unless a part is very thin, the cooling rate may be limited by the part thickness and not the mold temperature. In such a case low coolant and mold temperatures would provide little or no benefit. Perhaps a mold can be run at a higher temperature without an adverse effect on the cycle. This strategy can yield savings in pumping capacity, energy cost, and possibly a part-quality bonus.

Don’t be shy about experimentation with cooling parameters. Resin processing guides generally suggest a fairly broad range of allowable mold temperatures. Use antifreeze and very low temperatures only in specialized molding applications and when absolutely needed. Say yes to turbulence but no to overkill.

ABOUT THE AUTHOR

Phil Burger, P.E., founded Burger & Brown Engineering, Inc. in 1978 and served as president until 2005. Based in Grandview, Mo., Burger & Brown manufactures engineered products related to mold cooling and in-mold sensing and holds 10 patents for its products. Burger currently works part-time for the firm and has most recently developed an educational program called Scientific Cooling that was launched in October 2013. Contact: (816) 878-6675; email: trumpetman44@hotmail.com; web: www.smartflow-usa.com.

Related Content

The Strain Rate Effect

The rate of loading for a plastic material is a key component of how we perceive its performance.

Read MoreFormulating LLDPE/LDPE Blends For Abuse–Resistant Blown Film

A new study shows how the type and amount of LDPE in blends with LLDPE affect the processing and strength/toughness properties of blown film. Data are shown for both LDPE-rich and LLDPE-rich blends.

Read MoreHow to Set Barrel Zone Temps in Injection Molding

Start by picking a target melt temperature, and double-check data sheets for the resin supplier’s recommendations. Now for the rest...

Read MoreThe Importance of Melt & Mold Temperature

Molders should realize how significantly process conditions can influence the final properties of the part.

Read MoreRead Next

Processor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read More