PPA Adds Four to 2017 Membership Roster

PPA is a non-profit organization with a roster of more than 160 members, all of whom have at least 20 years of experience in plastics.

The Plastics Pioneers Association (PPA), McHenry, Ill., has announced that four new members have been selected to join the organization.

The new inductees, announced at the group’s November meeting in Arlington, Va. are:

Walt Bassett: Walt Bassett earned his Bachelor’s Degree in Chemistry/Chemical Engineering at Northeastern University–Boston; his Masters in Polymer Science & Engineering at the University of Massachusetts–Amherst; and did post graduate studies at Harvard & Babson College. He began his career at GE Plastics in 1984, moved to Weiss-Aug in 2000 as vice president of operations and engineering, then to Cooley Group in 2003 as vice president of operations. In 2004 Bassett moved on to Novartis/Ciba Vision as global head of R&D, then to Millipore in 2008 as director of R&D, and then joined Perkin Elmer in 2011 as director of R&D and product planning. Bassett is now director of product engineering at SunTech Medical, driving technical innovation in life science products.

Bassett has been a member of the American Chemical Society for more than 35 years, an SPE member since 1986, and is a past member of the Plastics Industry Association (formerly the Society of the Plastics Industry). He has received several industry awards for the development of innovative products, published 25 papers to prominent industry journals, has been issued nine patents and managed development teams that have been issued more than 50 patents.

Bassett is also Chairman of the Board for the Polymer Center of Excellence in Charlotte.

Dr. Robert S. Brookman: Dr. Robert Brookman’s earned a BS in Chemistry from the City College of New York and a PhD in Polymer Science from NYU. His industry experience includes 14 years as director of R&D at Firestone Plastics; 10 years as vice president of technology and board member of Pantasote Inc.; five years as vice president of Franklin Plastics; 12 years as president of Colorite Plastics; and 17 years at Teknor Apex and currently serves as their senior vice president of business development.

Dr. Brookman is a member of numerous industry organizations, including the Plastics Industry Association, Society of Plastics Engineers, the Vinyl Institute, the Bioplastics Council’s Phthalate Panel, the American Chemical Society (as Emeritus Member) and has been acknowledged by his industry peers as Vinyl Industry Man of the Year and as an SPE Fellow.

The holder of several patents, Dr. Brookman has published articles in the SPE Journal, the Journal of Polymer Science and Adhesives World and has presented technical papers at ANTECs, RETECs and the Brighten Conference.

Eric Carlson: Eric Carlson completed his Associate and Bachelor Degrees in Mechanical Engineering Technology at Wentworth Institute of Technology and obtained his Professional Engineering License in Mechanical Engineering. He later went on to earn an MBA from Bryant University.

Carlson’s industry experience began at Baker Brothers/Systems Engineering as a mechanical engineer in their design group. His responsibilities included equipment design for the plating and wet process industries throughout the US. He currently holds the position of director of engineering at Toray Plastics America, one of the largest producers of metallized biaxially oriented polyester and polypropylene films.

Carlson is a member of the Industrial Advisory Board to the Department of Mechanical, Industrial and Systems Engineering at the University of Rhode Island. For many years he has been in a project sponsor support role to the Mechanical Engineering Department’s senior capstone program through his company’s sponsorship of capstone projects.

Jorge Guzman: Jorge Guzman completed his B.S in Civil Engineering from Clemson University in 1975 and obtained his Professional Engineering License in Structural Engineering to work at nuclear power plants.

Guzman began his career in the plastics industry in 1983 with Luwa Corp. designing gear pumps, control systems and gravimetric metering systems. He joined Maag Automatik in 1992 and currently serves as their sales manager for the Southwest U.S., Central and South America and the Caribbean.

Guzman is a member of the National Society of Professional Engineers, the American Society of Civil Engineers, SPE and the National Association of Sales Executives. He has made technical presentation at several industry trade meetings and SPE conferences in the U.S., Europe, Mexico and South America.

Founded in 1944, the PPA is a non-profit organization with a roster of more than 160 members, all of whom have at least 20 years of experience in plastics. The group’s primary purpose is to award scholarships to students seeking a career in plastics, to provide grants to various plastics educational programs, and to preserve the history of the industry.

Related Content

Foam-Core Multilayer Blow Molding: How It’s Done

Learn here how to take advantage of new lightweighting and recycle utilization opportunities in consumer packaging, thanks to a collaboration of leaders in microcellular foaming and multilayer head design.

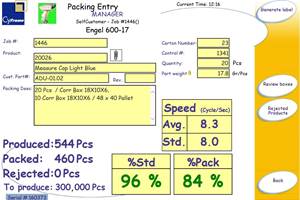

Read MoreUse Interactive Production Scheduling to Improve Your Plant's Efficiencies

When evaluating ERP solutions, consider the power of interactive production scheduling to effectively plan and allocate primary and secondary equipment, materials and resources on the overall production capacity of the business and conclude that this is a key area that cannot be overlooked.

Read MoreSolve Four Common Problems in PET Stretch-Blow Molding

Here’s a quick guide to fixing four nettlesome problems in processing PET bottles.

Read MoreMold Opaque White PET Bottles – Without Pigment

Trexel and Husky are cooperating on molding recyclable opaque white preforms for PET bottles, which provide a light barrier using foam instead of pigment.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read More

(2).jpg;maxWidth=300;quality=90)