Rethinking Machine Nozzle Tips: Hybrid Design Boosts Flexibility, Efficiency

New cold-sprue and hot-runner nozzle tips promise utility across a wide range of materials, eliminating the need to swap out different tips for different jobs while also promising to solve scrap and process issues.

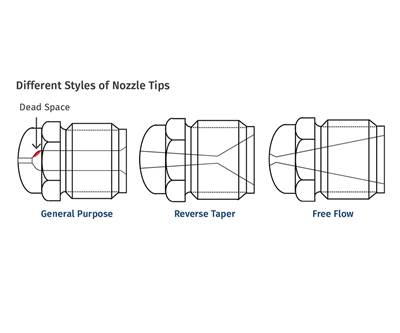

Despite their integral role in delivering plastics from the barrel to the mold, common general-purpose nozzle tips have design features that can negatively impact process stability and, in some cases, part cosmetics. Today, injection molders typically have three nozzle-tip options: general-purpose; reverse-taper or nylon tip; and the free-flow or full-taper tip.

PCS Company has introduced a cold-runner machine-nozzle tip that incorporates elements of all three of those designs, allowing it to be used across a wide range of materials; eliminating the need to stock and install different ones; and also solving some scrap and processing issues along the way.

In addition, to address hot-runner molds, PCS has developed a special hot-runner nozzle tip. The three common nozzle tips mentioned above all feature internal geometry designed to be used with a cold sprue, so when they’re paired with a hot runner they can result in dead spots and pressure loss, according to Randy Kerkstra, a PCS outside sales representative .

In this new hot-runner tip, all internal geometry is eliminated and replaced with a constant taper that removes pressure-loss and hang-up areas. When placed before a hot runner, a standard cold-sprue tip has hang-up areas where materials can build up, degrade and, at some point, break off into the flow, resulting in defects.

Freezing and Stringing Catch 22

When Kerkstra and PCS developed the tips, they found customers running jobs that could be improved by the design and had them test them out. Steve Gerritsma, production manager at Royal Technologies, Hudsonville, Mich., was experiencing recurring issues with an a acetal job. Running an office-furniture part on a four-cavity cold-runner tool with a cycle time of 37 sec, the process was plagued by the general-purpose tip freezing off and stringing off the nozzle.

After switching to the new tip, Gerritsma said the material appeared to fracture cleanly upon exit with no strings or roughness. He also noted that peak injection pressure dropped from around 14,200 to 12,000 psi. Reviewing the previous pressure profile, Gerritsma believed that there was a cold slug present in the old general-purpose tip, which required higher pressure to clear from the nozzle. With the new tip, this initial peak is not as high.

“From my experience, the biggest benefit that I saw was reduction in strings,” says Gerritsma. “Now we get less material buildup on our mold, less on the robot end-of-arm tool, and less on the robot itself—so that’s a tangible benefit.” By reducing nozzle-tip freeze-off, the company has also reduced the time spent using a torch to reheat the nozzle—one method that was previously employed to deal with the issue. “If we can eliminate some of that hassle,” Gerritsma adds, “that will save time for our supervisors and staff and increase uptime for our machines.”

“Molders have a constant battle of the cold sprue sucking the heat out,” Kerkstra explains, “so people play with the tip temperature, and that’s why you get freeze-off. So then people crank up the temperature on the front zone, which is their nozzle, to address freeze-off, and they get stringing.”

To solve this, the new cold-sprue tip design is intended to offer more of a thermal barrier than a general-purpose tip but not as much as a nylon tip. “It’s kind of a happy medium where it really helps and you have less pressure loss with this tip and the elimination of dead spots,” Kerkstra explains. “So it’s kind of a blend of all three and it’s been used across numerous materials.”

Cold-sprue tips will initially launch with two sizes—3/32 in. with ½-in. and ¾-in. radius. For hot runners, the two most common sizes—8- and 10-mm orifice with ½-in. and ¾-in. radius—will be stocked, with plans to expand those sizes and potentially incorporate other customizations, including different thread sizes, extended tips and more. “There’s quite a bit of opportunity to expand these into different machines and different thread sizes,” Kerkstra says. “We started out with the most common, but there’s definitely a lot of opportunity to expand this to a much broader tip market.”

A More Stable Process

Molding military parts from acetal and PBT where inconsistency, variations or gate blemishes are not an option, Seabrook Plastics, Muskegon, Mich., is constantly seeking a stable process. The company, which has 25 injection machines from 15 to 1320 tons, with the bulk in the 100- to 400-ton range, also trialed the new PCS tips. “The ability to just be able to start a job up and run it without having significant start-up scrap is a huge improvement for us, so these tips do make a pretty substantial difference,” explains Al Claeys, engineering manager.

Prior to using the new cold-sprue tip, the company adjusted with nozzle temperatures in a process that required regular tweaking. “We did a lot of manipulation of the nozzle temperature,” says Ray Thielen, manufacturing engineer. “So with cold slugs you’re fighting too cold, and splay could be too hot, so we’re going back and forth and changing it from lot to lot.”

“These seem to help us dial in our process a little bit tighter,” Claeys states, “and get a little bit better control and shot-to-shot repeatability.”

In addition to a new design, the tips are also manufactured well, according to Thielen. “I think the orifice size accuracy is more consistent,” Thielen says. “It’s machined better than some of the cheaper tips where you can get a 5/32 and a 3/16, and they’re not that different.”

For Kerkstra, the old adage—you get what you pay for—applies here. “The real cheap tips on the market—there’s a reason they’re real cheap. I have some molders that won’t even purchase a low-cost tip because the radius, orifice and lands vary.”

Related Content

Back to Basics on Mold Venting (Part 1)

Here’s what you need to know to improve the quality of your parts and to protect your molds.

Read MoreHow to Optimize Pack & Hold Times for Hot-Runner & Valve-Gated Molds

Applying a scientific method to what is typically a trial-and-error process. Part 2 of 2.

Read MoreBack to Basics on Mold Venting (Part 2: Shape, Dimensions, Details)

Here’s how to get the most out of your stationary mold vents.

Read MoreOptimizing Pack & Hold Times for Hot-Runner & Valve-Gated Molds

Using scientific procedures will help you put an end to all that time-consuming trial and error. Part 1 of 2.

Read MoreRead Next

How to Pick, Remove, and Replace a Nozzle Tip

This small component can cause big problems. Here’s my procedure for picking and replacing yours.

Read MoreProcessor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read More