Gently Does It

Unique R&D experience in urethane chemistry created a niche for New England Urethanes in North Haven, Conn., a small, highly specialized compounder serving medical-device manufacturers.

Unique R&D experience in urethane chemistry created a niche for New England Urethanes in North Haven, Conn., a small, highly specialized compounder serving medical-device manufacturers. NEU was started 10 years ago by four partners who had worked together since the 1960s and '70s in the R&D lab at Upjohn Co. near their present plant. Dow Chemical Co. bought Upjohn's polyurethane business in 1985 and closed the North Haven lab in '89. The four chemists and engineers then decided to turn their polyurethane compounding expertise into a company of their own aimed at the specialized market for medical compounds.

The four partners and directors take turns being president. Costas Georgacopoulos is director of engineering; Curtis Smith, director of R&D; Joseph Martucci, director of manufacturing; and Robert Maler, director of finance (and current president). The company has seven other employees beside the four directors.

Quality, not quantity

Most compounders of commodity resins run high-volume,low-profit materials 24 hours a day, seven days a week," Georgacopoulos notes. "We're the opposite. Our polymers are low-volume and highly specialized for applications where quality is demanded. We run very controlled output to preserve the polymer's properties. Our jobs tend to be smaller, our margins are higher, and, in our area of expertise, we feel we make better products." An average run is 3000-4000 lb, but NEU will run lots as small as 50 lb. It sometimes also runs up to 10,000 lb in one day.

NEU also repelletizes polyurethanes to upgrade their market value. For example, it turns pellets of uneven size into uniform pellets that will run smoothly in a medical tubing line. Or it takes ground automotive and industrial scrap and reprocesses it into pellets. Since TPU is expensive ($2.90-$3.40/lb tl), reprocessing and repelletizing it can recover a lot of value for customers.

NEU offers 100 colors of its own TPU compounds, trade named Neuthane, plus a series of soft TPU compounds (down to 65 Shore A) made by alloying a proprietary blend of urethanes. NEU also creates medical masterbatches of up to 80% barium sulfate or 50% bismuth subcarbonate in polyethylene or polyurethane. However, because of the critical nature of its medical business, NEU won't touch formulations that contain potentially contaminating materials, such as fiberglass.

In addition to medical products, NEU also serves markets as diverse as sneakers, computer keyboards, and in-line skate wheels. Roughly half its business is in its specialty of thermoplastic polyurethanes, but the firm also compounds polyolefins, ABS, nylons, and polycarbonate--about 400 different formulations in all.

Another value-added service is refining or homogenizing TPUs to give processors a narrower range of MFI, pellet size, or other properties than are available directly from resin companies. Homogenizing involves blending and drying TPUs and then very gently re-extruding them so that as little degradation as possible takes place.

Low rpm, high output

Georgacopoulos says, "A lot of people run urethanes, but not well." Running TPUs gently is NEU's secret. The homogenizing process, for example, involves a single-screw compounder--a 3.5-in., 30:1, air-cooled MX extruder from Merritt Extruder, Hamden, Conn. It has a special low-shear screw, jointly designed by NEU and Merritt.

"It pumps significantly more plastic per screw rpm, so you can run slower, but get more lb/hr," says Merritt president Sandy Guthrie. "The extruder was designed for 300 lb/hr, but with this screw it consistently exceeds 500 lb/hr," he adds. Normal screw speed for TPU extrusion would be 35-40 rpm, but this line runs at 40-65 rpm. It is used to homogenize large lots of TPU to achieve consistent properties while increasing MFI as little as possible.

Meanwhile, NEU is growing. This month, the company moves from its rental quarters to a new 17,000-sq-ft plant that it purchased nearby. The firm will also soon add a fifth, bigger compounding extruder

Related Content

Tracing the History of Polymeric Materials: Aliphatic Polyketone

Aliphatic polyketone is a material that gets little attention but is similar in chemistry to nylons, polyesters and acetals.

Read MoreTracing the History of Polymeric Materials: Acetal

The road from discovery in the lab to commercial viability can be long, and this was certainly the case for acetal polymers.

Read MoreWhat's the Allowable Moisture Content in Nylons? It Depends: Part 2

Operating within guidelines from material suppliers can produce levels of polymer degradation. Get around it with better control over either the temperature of the melt or the barrel residence time.

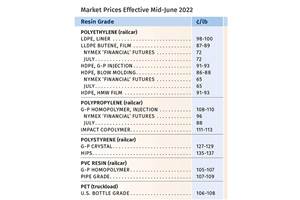

Read MoreVolume Resin Prices Move in Different Directions

PE, PP, PVC, and ABS prices slump, while PS, PET, PC, and nylons 6 and 66 prices rise.

Read MoreRead Next

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More (2).jpg;maxWidth=970;quality=90)