Profile Maker Runs Lean & Fast

In the early 1990s, as competition heated up in European PVC window markets, many European processors looked to U.S. markets for growth.

In the early 1990s, as competition heated up in European PVC window markets, many European processors looked to U.S. markets for growth. However, KBE Kunststoffproduktion GmbH in Berlin looked East, opening sales offices and warehouses in former East Bloc countries.

KBE was accustomed to political risk. Its original choice to build in West Berlin in 1981 was a calculated risk to take advantage of government incentives to bring jobs to the city during the Cold War. The plant was in sight of the Berlin Wall less than a mile away. When the wall fell in 1989, KBE was well situated to open offices swiftly in Poland, the Czech Republic, Russia, Lithuania, Kazakhstan, and Belarus. Last year, it even started profile extrusion near Moscow.

KBE rode an early wave of home rebuilding and window replacement in Eastern Europe. Fortunately for KBE, East European window profiles are based on the German standard, whereas U.S. and other Western European markets require different tooling.

KBE has two compounding plants in Berlin able to produce a total of 176 million lb/yr of PVC dryblend. Compounds are bagged and sent to KBE's plants in Spain and Russia. The new Russian plant has five profile extrusion lines, while the firm's plant in northern Spain has four. All extruders in the company are less than six years old.

Built for speed

The highly automated Berlin plant sets the technology pace for all KBE's facilities. It has 55 PVC profile lines, all with parallel twin-screws of 3.5- to 5-in. diam. They produce a total of 110 million lb/yr. The plant runs seven days, 24 hours in four shifts with a lean staff of 20-25 per shift, including quality control and supervisors. That's roughly one person for every three extrusion lines.

Extruders, pullers, saws, and cutting tables come mostly from Battenfeld Extrusionstechnik GmbH, a unit of SMS Plastics Technology in Bad Oeynhausen, Germany (represented in the U.S. by American Maplan, McPherson, Kan.). Disc dies and calibrators are from Schwarz Extrusionsverkzeuge GmbH in Wolfratshausen, Germany (49% owned by SMS and also represented by Maplan). Automated packing equipment is built by Stein Maschinenbau GmbH in Hinterweidenthal, Germany.

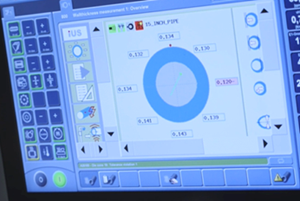

The Berlin extrusion lines use Battenfeld's Unilog TC40 transputer controls, and the display panels are mounted high enough to be read from a distance. They show real-time line speed in large red numbers. Lines producing window sashes, transoms, and frames typically run at 13-16 ft/min. These profiles weigh about 1 lb/ft. The Berlin plant's scrap rate is a modest 3.5 to 4%, all of which is reused in the core of a coextrusion. "When you start up a line, you should have no more than eight to 10 damaged profiles," says production manager Werner Platvoetz.

To achieve high speed, the Berlin plant starts with extra-long dies—up to 14 in. instead of the typical 8-10 in. KBE doesn't build its own dies, but its staff of 15 toolmakers modify them for higher output.

Vacuum-calibrating tanks over 40 ft long plus 7-ft spray-cooling tanks circulate an enormous volume of water. One section of the Berlin plant with 20 single-strand lines for sash profiles uses 150,000 gal/hr of water chilled to 54-55 F. For complex profiles, KBE sucks hot air out of the internal chambers.

KBE plants in Russia and Spain can't match Berlin's speed yet. The Urssa, Spain, operation extrudes sashes and frames at 8-10 ft/min, but the new Moscow plant runs at 10-12 ft/min. "They are learning," says Platvoetz. "It takes a lot of processing know-how and training to run at these speeds without error."

Speed record

Last September, KBE started up a new line in Berlin that is believed to be the fastest window-profile line in the world. It's a 5-in., 25:1 Battenfeld BEX2-130-25 system with output of up to 1700 lb/hr. It can run complex dual strands at up to 13 ft/min. Effective output is thus 26 ft/min. This racehorse line has a larger drive motor (177 hp) than is typical for a machine of its size.

Other lines at KBE produce smaller profiles with up to four strands. One line makes four glazing beads at 33 ft/min, a total linear output of 132 ft/min.

Related Content

Fully Automated Extrusion Process Enables Use of Composites for Manufacturing Pressure Tanks

Amtrol was looking for a more cost-effective means to produce thin-wall liners for a new line of pressure tanks. With the help of a team of suppliers, they built one of the world’s most sophisticated extrusion lines.

Read MoreCooling the Feed Throat and Screw: How Much Water Do You Need?

It’s one of the biggest quandaries in extrusion, as there is little or nothing published to give operators some guidance. So let’s try to shed some light on this trial-and-error process.

Read MoreHow to Estimate and Control Head Pressure

You rightfully worry about melt temperature, but don’t overlook head pressure, because the two are closely linked and will influence line performance.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MoreRead Next

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More

(2).jpg;maxWidth=300;quality=90)