Technology Power for Better Intelligence and Optimization

Autodesk is pushing better intelligence for part and mold design with its MoldFlow products and optimizing overall manufacturing with its Delcam tools and CAM specialty products at Booth W8147 in the West Hall.

Autodesk is pushing better intelligence for part and mold design with its MoldFlow products and optimizing overall manufacturing with its Delcam tools and CAM specially products at Booth W8147 in the West Hall.

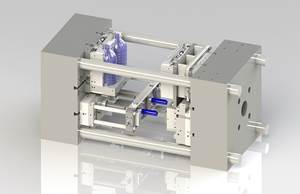

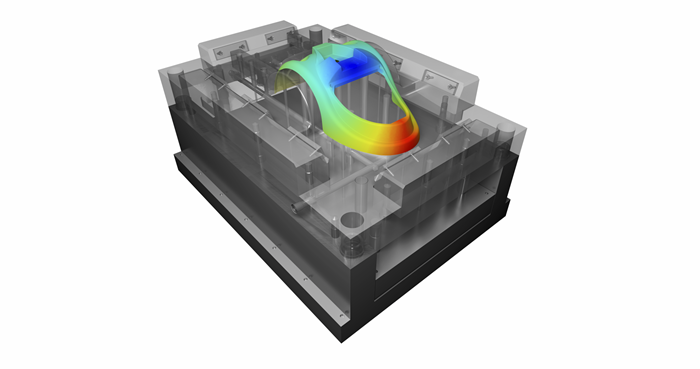

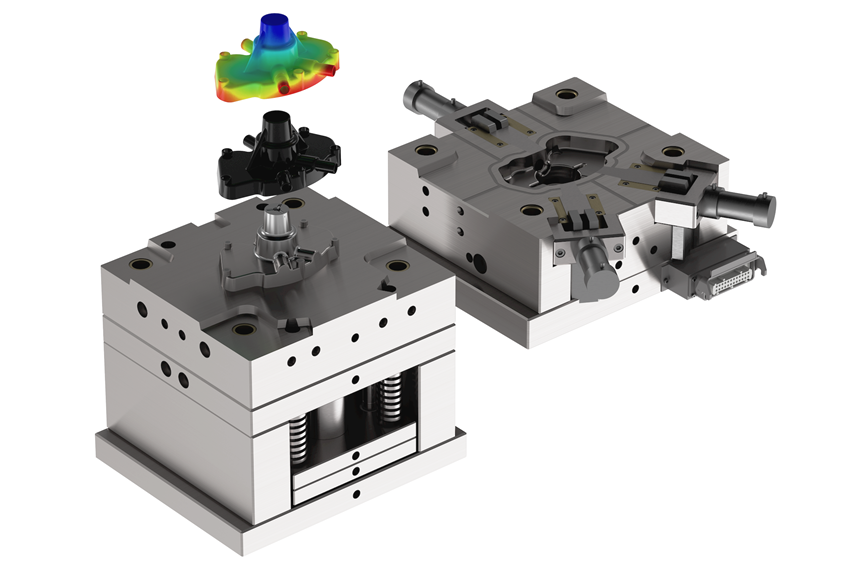

Autodesk’s booth has three demonstration stations, a charging table and theater focused on its Moldflow Solutions (Insight and Helius), Moldflow for Design (Adviser and MF Design) and Manufacturing (Delcam) product lines. Moldflow Insight is a complete set of advanced plastics engineering simulation tools; Helius Composite software offers detailed information on composite material behavior without finite element analysis (FEA); Moldflow Adviser is plastic simulation tools to optimize part and mold designs to ensure molded part quality and manufacturability, and PowerMill CAM software provides comprehensive milling strategies for high-speed and five-axis machining.

“A big trend with the MoldFlow user base is automation. That means, being able to automatically explore and utilize more of the technology power to consider different solutions for optimizing upfront design; more design options. Users can now use simulation to look into the performance of the tool before they actually create it, using that as an exploratory option," Mark Hennebicque, business line manager at Autodesk says.

On the CAM side, the company launched PowerMill 2019 last month and is showcasing its new features and functions, including a dedicated suite of strategies to help program the growing number of CNC machines that offer both additive and subtractive technology. PowerMill is capable of driving both wire-fed and powder-blown hardware with three- and five-axis machine motion.

For five-axis machining, a new “automatic tool axis tilting” method simplifies the creation of collision-free toolpaths. This single solution creates smooth and safe five-axis motion for all model shapes and toolpath types, making it as easy to create five-axis programs as it is to produce three-axis code, according to the company. Also, PowerMill’s Vortex high-efficiency roughing strategy now includes a new “From Stock” option that uses “Adaptive Clearing” to produce toolpaths that machine parts with considerably shorter cycle times than previous releases.

For 2D machining, PowerMill provides an improved workflow for the definition of open-sided 2D features. These can now also be created based on a selection of surfaces reducing programming even more. PowerMill’s ViewMill stock simulation tool offers a “Remaining Material” shading mode. This helps CAM programmers to identify areas of un-machined stock, to ensure parts are completed before removing from the machine. PowerMill 2019 includes a direct interface to Autodesk Fusion Production, a cloud-based collaboration tool specializing in scheduling and tracking production, and monitoring CNC machine utilization.

Theater presentation topics this week include meshing improvements; comparing Moldflow Adviser to Moldflow Insight; cooling, beyond the results; weldline strength; MuCell; shrink and warp; CAM; matching simulation to process settings; conformal cooling 3D-printed inserts; importance of materials properties and testing; valve gate simulation and cloud advantages.

Other educational opportunities include Autodesk's participation in the ANTEC Technical Conference Program with presentations on deformation and stress prediction of injection-molded components after being mounted into designed position; the effects of stress relaxation on shrinkage and warpage of injection-molded parts; using a new anisotropic rotational diffusion model to improve prediction of short fibers in thermoplastic injection molding; and numerical and experimental studies on flow and warpage during resin transfer molding process.

On top of all the technology talk, Autodesk is hosting a pizza, beer and wine reception at its booth on Wednesday, plus two sponsored receptions offsite: Penn State Alumni Reception on Tuesday at Marlow’s Tavern at the Pointe from 6-9 p.m. and UMass Lowell Reception & Dinner that same night at the Rosen Center Hotel, starting at 5p.m.

Last but not least, Moldflow also turns 40 this year and Autodesk is celebrating all week by showcasing the tool's birth in 1978 all the way through to 2018 using a graphic timeline to highlight a few key milestones. Don't forget to grab your commemorative computer camera cover, keychain or water bottle before you continue down the aisle.

Related Content

At NPE, Cypet to Show Latest Achievements in Large PET Containers

Maker of one-stage ISBM machines will show off new sizes and styles of handled and stackable PET containers, including novel interlocking products.

Read MoreReal-Time Production Monitoring as Automation

As an injection molder, Windmill Plastics sought an economical production monitoring system that could help it keep tabs on its shop floor. It’s now selling the “very focused” digital supervisor it created, automating many formerly manual tasks.

Read MoreSix Years in the Waiting, PLASTICS Igniting a ‘Spark’ at NPE

New features of NPE2024 aim to “bring the whole plastics ecosystem together to innovate, collaborate and share findings.”

Read More420 Stainless Steel Now Qualified With TrueShape 3D Printing Technology

NPE2024: Mantle's Additive Manufacturing Technology is Designed for Precision Tooling

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More

(2).jpg;maxWidth=300;quality=90)