Blenders & Feeders

Blenders should be considered as part of any central plastics conveying system. Materials are fed to blenders just as they are fed to drying hoppers and process machines with Vacuum Loaders, Receivers or Venturi Loaders.

The recommended practice is to mount blenders over the process machine because ingredients may separate if transferred through long vacuum lines. If the materials being blended can be transported to the blender from a central storage area, through your central conveying system, that eliminates more containers and activity in the production area and greatly reduces waste of valuable additives.

Usually, the main ingredient can be pulled from the central system bulk storage area while other ingredients may be stored in drums and gaylords in a separate area and transported by a dedicated central system. Anything you can do to get resin containers off the production floor will improve your efficiency.

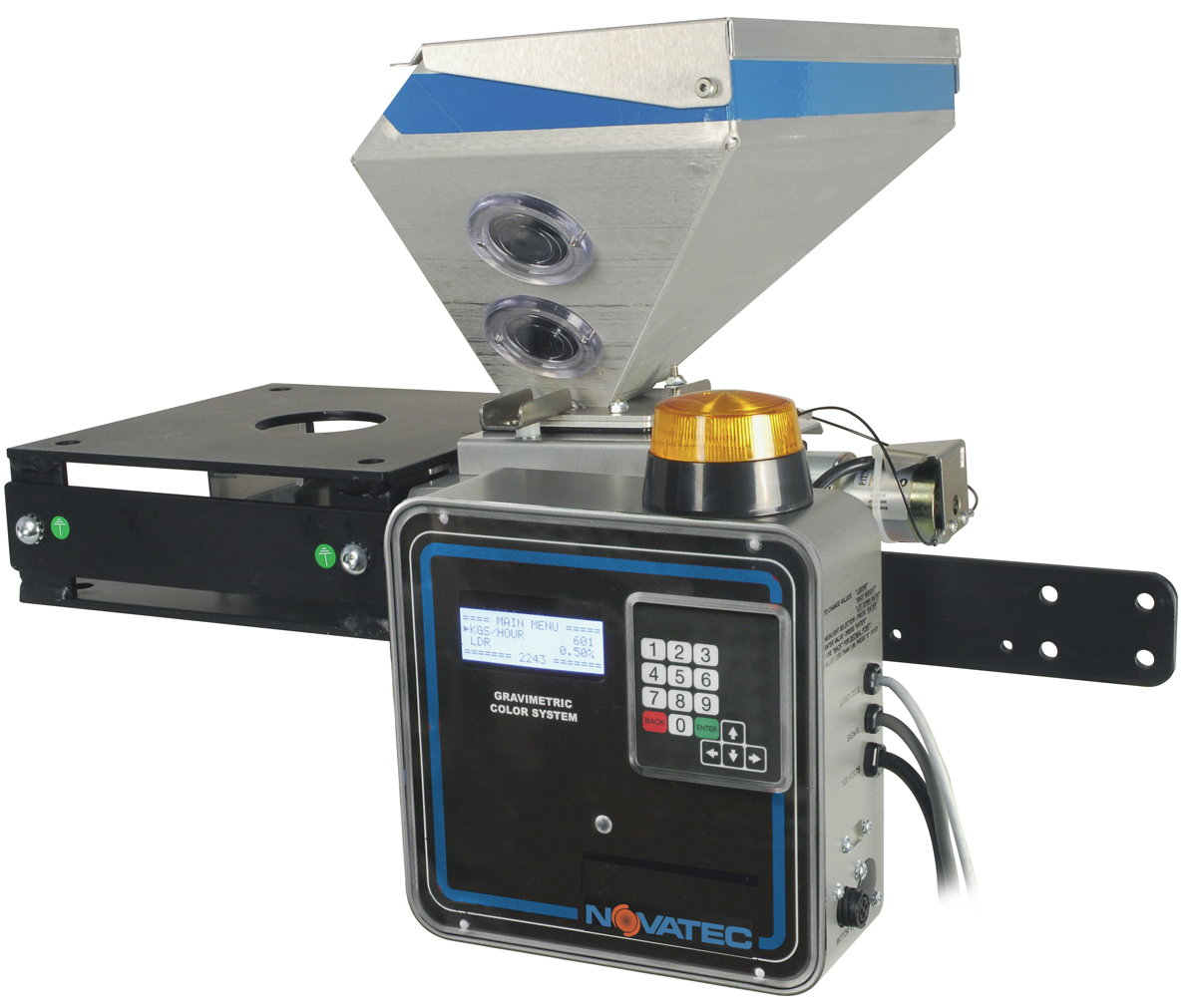

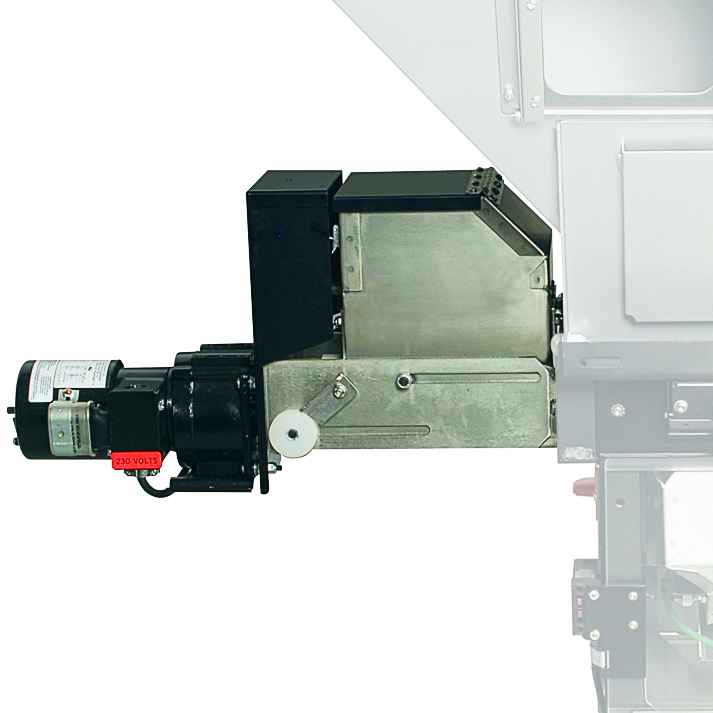

Gravimetric blending and dosing is a huge money saver in itself because it is so much more accurate than other methods of blending materials...far more accurate than proportioning valves or volumetric methods. Yet, there is a great demand for volumetric feeders for specific purposes.