Vacuum System Types

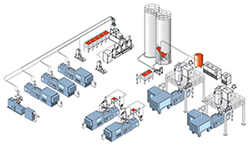

Plastics conveying systems commonly fit into one of four categories and are typical for certain processes. Some exceptions may occur.

• Single Source - Single Destination: Extrusion, Thermoforming, and Injection (preforms)

• Single Source - Multiple Destinations: Extrusion, Injection (caps), and Blowmolding (containers)

• Multiple Source - Single Destination: Extrusion

• Multiple Source - Multiple Destinations: Injection, Extrusion (tubing, wire & cable)

Many crossover situations may affect the system selection process but typically the processor listed in the above business will employ the type of resin conveying system shown.

Here are additional factors that may need to be taken into consideration:

- Does the resin require drying?

- Are multiple source materials involoved similar, such as PE and PP?

- Is a common or dedicated line conveying system preferred or required?

- Do you need dry or ambient air conveying?

- Are material selection manifolds required?

- Is verification and validation of materials critical?

- Is line purging required?

All of these questions are best discussed with a systems engineer who will help guide you through your selection process.

There are also sub-systems which are usually considered separately but can be integrated into the primary resin conveying system.

System Integration

When considering a central resin handling system, it’s best to include all parts of the process if possible. Anything you can do to declutter the production floor will result in a better workflow, fewer employees and increased profits.