Vacuum Pumps

Correct Pump Selection Is Critical to Conveying System Health

Like the heart that keeps our blood flowing through our bodies, vacuum pumps keep resin flowing through your processing facility so they are critical to the health of your conveying system.

It is important to understand the differences between pump types so you can:

- Maximize the efficiency of your resin conveying system.

- Minimize line plugs, maintenance and machine starving.

- Expand an existing conveying system without ripping out existing lines.

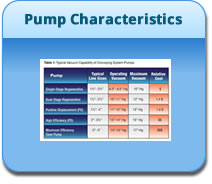

Air and vacuum work together to make everything happen in a resin conveying system. Airflow creates the velocity to pick up and move the resin through the pipes. Vacuum energy overcomes the resistance created by air and material as they move through the pipes. The conveying system’s “engine” is the pump, which is the source for airflow and vacuum. (See Basic Performance Characteristics of Pumps)

An integral filter and an external cyclone dust collector are used to keep stray dust and fines out of the vacuum pump. A highly effective cyclone dust collector is an important component to ensure extended pump life. It should remove 99% of dust and fines from the airstream.