Association of Plastics Recyclers Recognizes Cavitated PE Technology

Void Technologies’ VO+ PE Masterbatch Technology Achieves Critical Guidance Recognition

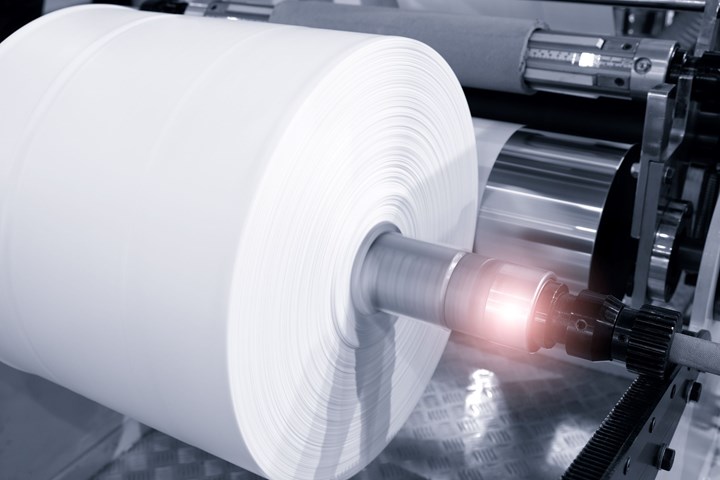

Void Technologies announced it has received Critical Guidance recognition from the APR for its proprietary process to create low density cavitated films, confirming its compatibility with PE film recycling in the US.

The VO+ technology creates micro and nano-scale air pockets in plastic, creating a film with a reduced environmental footprint.

Void’s film technology supports downstream recyclability.

Photo Credit: Void Technologies

VO+ films are produced by blending the masterbatch with PE as part of the film extrusion process. The orientation process causes the VO+ additives to separate from the primary polymer to create a non-breathable voided structure. The combination of MDO and cavitation leads to improved film performance including puncture resistance, toughness, and high opacity.

PE films produced using Void’s new process offer a 35% material savings from density reduction and down-gauging.

The APR recognition comes after laboratory testing confirmed that the technology is compatible with current, industrial-scale, film to film recycling processes. Thanks to the low density of VO+ PE films, they will float in separation systems. During the recycling process, VO+ films will turn from white to clear and will retain similar properties to recycled PE resins.

Void’s VO+ PE masterbatch technology was developed for use in a range of applications such as laminates, frozen food, wicketed bags, and flow wraps for confectionery.

Related Content

-

Compatibilizers Aid Recycling & Upcycling of Mixed Resins

Compatibilizers are proving their worth in boosting critical properties such as impact/stiffness balance of PCR and PIR blends of polyolefins and other plastics.

-

Evolving Opportunities for Ambitious Plastics Recycler

St. Joseph Plastics grew from a simple grinding operation and now pursues growing markets in recycled PP, food-grade recycled materials, and customized post-industrial and post-consumer compounds.

-

Purpose-Built System Enhances Capacity and Flexibility for Recycler

A Boston recycler invested in a turnkey shredding, granulation and elutriation system to expand its plastics reclaim business.