Injection Molding: New Software Shares Simulation Results Among Development Partners

New SigmaInteract software from Sigma Engineering helps different departments or project partners share simulation results.

At the K 2019 show in Düsseldorf next month, molding simulation software provider Sigma Engineering will present its new SigmaInteract. It allows different departments within a company, as well as different companies—project partners and customers—to share interactively the results of “virtual DOE” performed by Sigma’s Autonomous Optimization software (see Feb.’18 Keeping Up and May ’18 online feature).

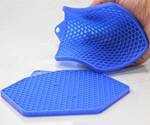

The possibilities for “interdisciplinary exchange” will be demonstrated at K through a live demonstration of molding a particularly challenging LSR application—a pot holder with complex geometry, thin walls and long flow lengths (see this issue’s injection molding K preview feature). For this project, part design and tool construction were conducted in parallel, so it was essential for all partners—LSR material supplier Momentive Performance Materials, toolmaker Emde MouldTec, and machine suppliers Wittmann Battenfeld and Nexus Elastomer Systems—to work closely together. Virtual DOEs by Sigma determined the optimum gating and heating arrangements and the need for venting, and helped in selecting the LSR material and redesigning part of the pot holder for faster cycling. Simulation also helped determine the minimum injection and clamp pressures needed, so that the smallest possible injection machine could be chosen for the project.

At the show, visitors to Sigma’s booth can see the pot holder being molded, both virtual and live, at the Wittmann Battenfeld booth. Results of both live molding and interactive 3D simulation results will be presented on the Wittmann Battenfeld machine controller via SigmaInteract—demonstrating how simulation and production can be linked together.

Related Content

-

Fakuma 2023: Wittmann Battenfeld Expands All-Electric Line, Direct-Current Capabilities

Wittmann Battenfeld will introduce the new EcoPower B8X injection molding machine line and show direct current as an energy source for a concept machine that will power its own robot.

-

Slimmer All-Electric Press Debuts

A slimmed-down version of Engel’s all-electric, e-mac injection molding machine is among eight displays, which also include LSR micromolding, quick mold changes and a cube mold.

-

New LSR Cold Deck

Hot runner supplier Mastip used K 2022 to introduce the customized and valve-gated Aquilo liquid silicone rubber (LSR) cold deck.