Part Feasibility Studies

CAE Services has analyzed tens of thousands of plastic injection molds, completing part feasibility studies including and moving beyond Moldflow simulation.

CAE Services (Batavia, Ill.) will showcase its part feasibility study capabilities at the PTXPO (March 29-31; Donald E. Stephens Convention Center; Rosemont, Ill.). The company notes that over the years it has learned that many injection molding problems can be avoided by paying attention to good part design and mold design standards.

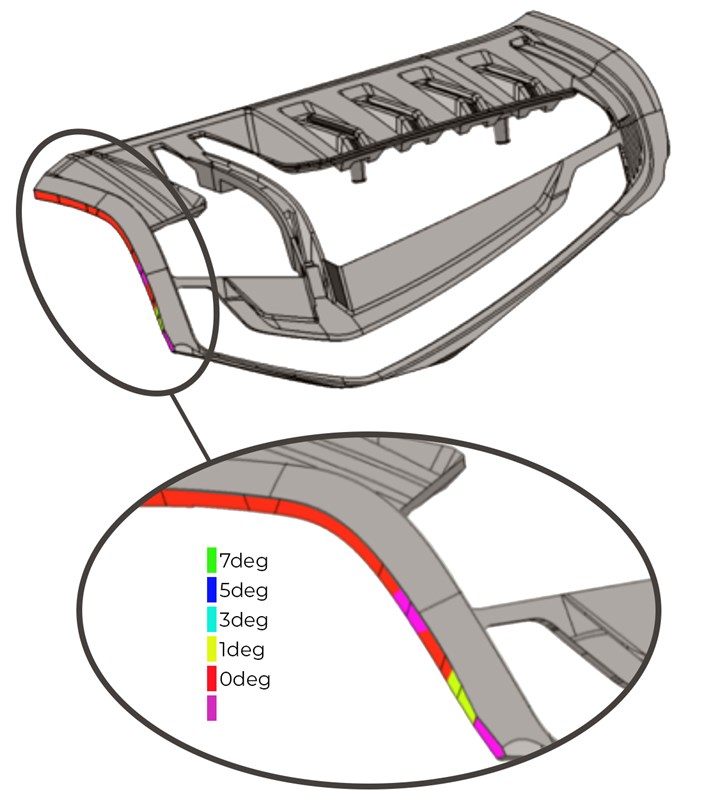

By undertaking in-depth part feasibility studies up front, many of the problems that occur in the molding process can be improved before CAE Services starts optimizing designs through Moldflow simulation. These services include: wall stock check to help identify excessive wall-stock variations that can help avoid excessive shrinkage variation; draft analysis, which identifies areas that need attention; and tooling action, which identifies areas and features of the part that will require lifters/slides, etc.

CAE Services will showcase its part feasibility study capabilities at the PTXPO (March 29-31; Rosemont, Ill.)

Photo Credit: CAE Services

Related Content

-

How to Set Barrel Zone Temps in Injection Molding

Start by picking a target melt temperature, and double-check data sheets for the resin supplier’s recommendations. Now for the rest...

-

How to Get Rid of Bubbles in Injection Molding

First find out if they are the result of trapped gas or a vacuum void. Then follow these steps to get rid of them.

-

A Simpler Way to Calculate Shot Size vs. Barrel Capacity

Let’s take another look at this seemingly dull but oh-so-crucial topic.