close up on technology

Injection Machines Use Novel Two-Stage Molding System

EdeX servohydraulic presses from Taiwan are the first to employ the Inject-EX plasticating system from Md Plastics.

Read MoreNovel System Produces Color on Demand

Ampacet’s FluxQF technology features a quick-dispersion universal carrier with novel machinery that provides automated color blending in quantities down to 50 lb.

Read MoreKraussMaffei Launches Two Additive Manufacturing Lines at K 2022

Long established in injection molding, extrusion and polyurethane reaction process machinery, 184-yr-old KraussMaffei prepares to enter the industrial additive manufacturing market.

WatchK 2022 Preview: Engineering Materials for Sustainability and E-Mobility

Materials that are sustainable yet offer equal performance to their fossil-based counterparts will be prominent at K 2022.

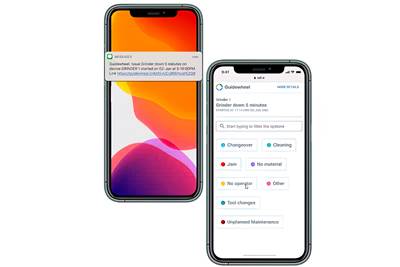

Read More‘Plug & Play’ Machine Monitoring For Small and Medium-Size Processors

New firm aims to bring benefits of real-time visibility of plant operations to smaller plastics firms at modest cost with quick and easy implementation.

Read MoreK 2022 Preview: Injection Molding Closes the Circle, Digitally

Because the market requires sustainability—and important component of which is the circular economy—and sustainability requires digitization, all three will be major themes at injection molding booths at K 2022.

Read MoreVariable-Diameter Air Ring Cools Film Above Frost Line

Tower-mounted adjustable ring adds cooling so that blown film can run at optimum line speeds with structures having soft inner skin layers that tend to block.

Read MoreAir Ring Add-On Brings Output to New Level

The Short Stack from Addex sits between the air ring and die and provides high-velocity air flow to boost output and lock in the bubble.

Read MoreHow Production Monitoring Can Make You a Better Processor

Real-time information on all your production equipment not only boosts productivity and profitability, but it encourages proactive vs. reactive thinking and sharing of best practices. See how this approach benefited a blow molder with 19 plants.

Read MoreCustom Molder Manages Growth on Several Fronts

Adding people, plants and machines, expanding capabilities in LSR, high-tonnage presses, automation and 3D printing—EVCO Plastics maintains momentum through challenging times.

Read More

(2).jpg;maxWidth=300;quality=90)