Injection Know How

How to Solve Uneven Clamping

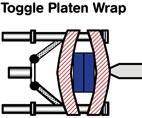

Of the hundreds of variables involved in injection molding, clamping mechanisms and platens often get less attention than they deserve.

Read MoreFind the Source of Visual Defects

The appearance of visual defects on parts such as cracking, crazing, grooves, ripples, wave marks, and flaky brittleness often indicates more than an aesthetic problem.

Read MoreSticking Sprues or Parts? Lots of Possible Causes and Solutions

Material sticking in the mold can be a production killer, whether it is the sprue or the formed part in the cavity.

Read MoreEliminate Surface Defects on Molded Parts

Visible defects on the surface of a molded part appear as dull, glossy, or hazy areas, or as a rippled surface, called orange peel.

Read MoreWhat You Can Learn from Shot Profiles

Want to know more about your molding process? Need a better way to diagnose problems? There's no better tool than the electronic 'signature' provided by process-monitoring curves of cavity pressure and other variables. Here's a sampling of seven real-world molding issues as revealed through shot profiles.

Read More