Molds & Tooling

How to Select the Right Tool Steel for Mold Cavities

With cavity steel or alloy selection there are many variables that can dictate the best option.

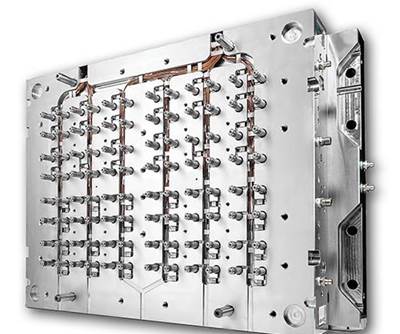

Read MoreHow to Optimize Pack & Hold Times for Hot-Runner & Valve-Gated Molds

Applying a scientific method to what is typically a trial-and-error process. Part 2 of 2.

Read MorePositioning Wedges for Precision Fixing of Mold Inserts

Hasco’s new Z1855/… positioning wedges allow users to change mold inserts in injection molding tools easily and lock them in place.

Read MoreMatrix Tool: Welcome to the Family

In its 50th year, Matrix Tool applies moldmaking and injection molding expertise, plus a long family heritage, to high-precision jobs that many would deem impossible.

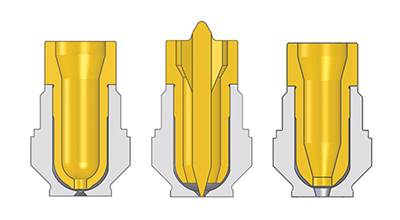

Read MoreHot Runners: A View from the Bottom Up

Addressing hot-runner benefits, improvements, and everyday issues from the perspective of decades of experience with probably every brand on the market. Part 1 of 2.

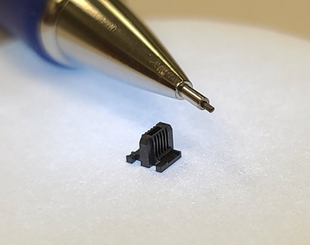

Read MoreCustom Manufactured Core Pins, Punches, Blades and Sleeves

Precision ground to ±0.000050 in, the components come in lengths up to 14 in with tip diameters as small as 0.002 in.

Read MoreDescaling Pump Cleans Heating and Cooling Circuits

Mouldpro’s compact and portable descaling pump keeps heating and cooling circuits on molds and molding machines clear of rust and limescale deposits.

Read MoreHow to Mount an Injection Mold

Five industry pros with more than 200 years of combined molding experience provide step-by-step best practices on mounting a mold in a horizontal injection molding machine.

Read MoreMold, Hot Runner, Digitization and Process Monitoring at K 2022

The Barnes Group’s Molding Solutions division companies will highlight new mold and hot runner technologies at its own booth and at several machinery partners during K 2022.

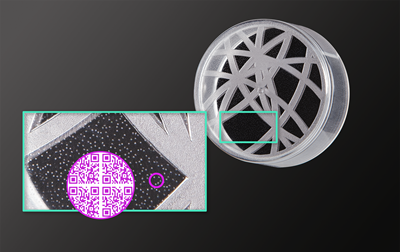

Read MoreHow Additive Manufacturing Can Help, not Hinder, Injection Moldability of New Designs

Four cost drivers—design for moldability, mold-base size, internal componentry, polish/custom finishing—dictate the financial and processing success of a molded part design. Learn how 3D printing can assist this process, while also understanding its potential pitfalls.

Read More