Tooling Know-How

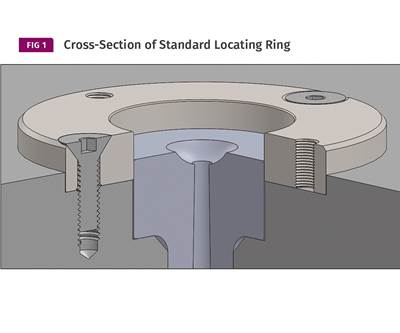

What You Need to Know About Locating Rings: Part 1

Selecting the right locating ring and putting it to good use takes a lot of thought.

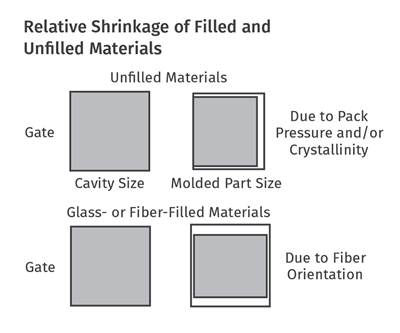

Read MoreHitting the Numbers, Part 2: The Shrinkage Factor

The shrinkage factor is one of the most critical numbers to hit.

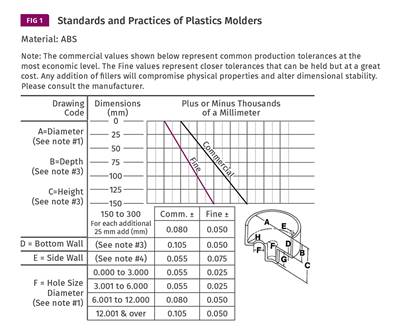

Read MoreHitting the Numbers, Part 1: Communication is Key

Start with an up-front review, discussion and collaboration with the customer.

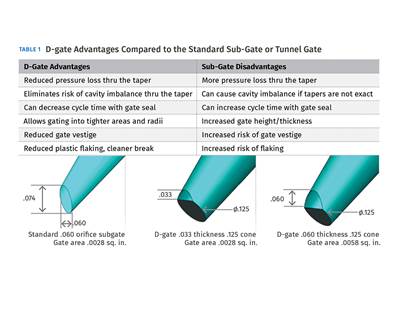

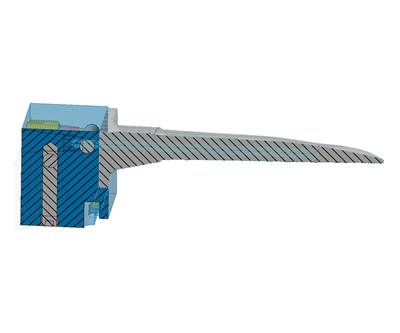

Read MoreGating Revisited

An overlooked factor in injection molding has outsize influence on the process and part quality.

Read MoreSolving Issues with Gloss

Your problem may be related to tooling, material, processing, or combinations thereof. Here’s how to find the root cause.

Read MoreTOOLING: Let’s Get Serious About Mold Cooling: Part 2

Some creative thinking with conventional technology, like small cooling lines and bubblers, can generate big improvements in cooling and cycle times.

Read MoreTOOLING: Let’s Get Serious About Mold Cooling

Cooling is crucial to the molding process yet frequently overlooked. Here are some insights to consider.

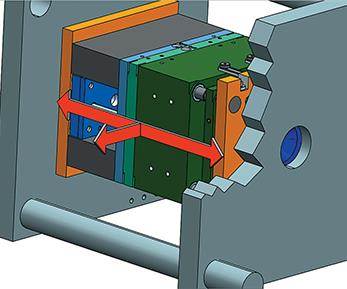

Read MoreTOOLING: The Tool’s Impact On the Molding Process

Flash, venting, cooling, gating, or sticking problems? Better to fix the tool than distort your process.

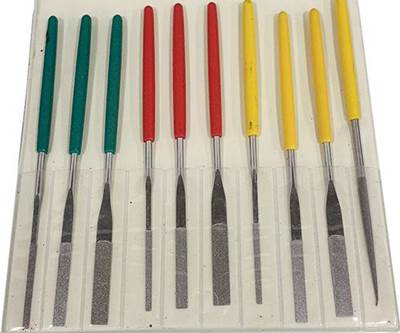

Read MoreTOOLING: Repairing Molds in the Press: Part 3

This is the final part of a series on tooling in the press. This column will cover repairs that can be accomplished in the press.

Read MoreTOOLING: Designing Molds for Easy Cleaning & Maintenance in the Press

Pay attention to water leaks and rust, proper grease selection, vent buildup, and checks for wear.

Read More