Barrier Blow Molding

Latest Barrier Blow Molding Articles

VIEW ALLHow Was K 2022 for Blow Molding?

Over a dozen companies emphasized sustainability with use of foam and recycle, lightweighting and energy savings, along with new capabilities in controls, automation and quick changeovers.

Read More50 Years...600 Issues...and Still Counting

Matt Naitove marks his first half-century in plastics reporting, with a few of his favorite headlines.

Read More50 Years of Headlines … Almost

I was lucky to get an early look at many of the past half-century’s exciting developments in plastics. Here’s a selection.

Read MoreStaying Ahead of the Curve: How a Blow Molder Thrives as a ‘Technology Company’

Aptly named Ring Container Technologies beefs up R&D staff to meet customers’ future needs before the customers even know what they will be.

Read MoreHoneywell Debuts Aclar Edge Barrier Bottles for Pharmaceuticals

Honeywell has expanded beyond Aclar barrier films into Aclar Edge barrier bottles for pharmaceuticals and other moisture- and oxygen-sensitive products.

Read MorePlasma “Glass” Barrier Coating Developed for Reusable PET Bottles

IKV and KHS Corpoplast in Germany collaborate on SiOx barrier coating that can withstand caustic washing for multi-trip PET bottles.

Read MoreLatest Barrier Blow Molding News And Updates

Injection Molding Gains an Edge in Motorcycle Gas Tanks

Complex shapes required for the latest motorcycle gas tanks favor injection over blow molding. Lanxess and BMW have a monolayer nylon solution.

Read More320 L Hydrogen Tank Liner Blow Molded in Nylon

Large liners for hydrogen composite pressure vessels are a challenge to blow mold. Kautex found a material and a technique to achieve a world “first.”

Read MoreThe New Uniloy Plans Numerous Machine Developments

Starting with barrier coinjection at K 2019, Uniloy plans new blow molding machinery developments across four product lines.

Read MoreBlow Molding: New Six-Layer Coex Head for Packaging

Kautex returns to in-house production of six-layer blow molding heads for packaging.

Read MoreInjection-Blow Molding Multi-Layer Barrier Bottles

Kortec hot-runner technology and an auxiliary injector convert a standard machine to three-layer co-injection blow molding.

Read MoreBlow Molding: Heavy-Duty Bottle Deflashers

A pair of high-impact bottle deflashers are designed for heavy-wall containers made of tough resins like PC and E-PET.

Read MoreFeatured Posts

Blow Molding: Something for Everyone at K Show

Packaging, industrial, continuous-extrusion, accumulator-head, injection-blow, stretch-blow, EPET, foam, sandwich co-injection—the blow molding news was wide ranging at K 2019.

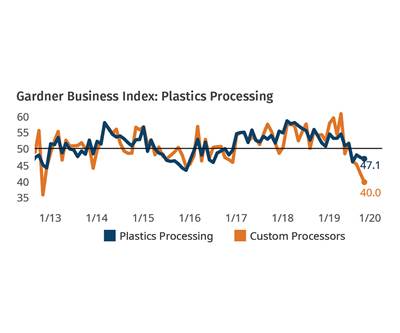

Read MoreIndex Dips on Weak Exports, Employment

October’s number drops from September, despite expansion in new orders.

Read MoreNPE2018 New Technology Focus: All-Electrics Multiply in Blow Molding

All-electric shuttles and injection-blow machines continue to proliferate.

Read MoreGet into the Zone: Bottles

Do you make bottles? At NPE2018’s new Bottle Zone, hear technical presentations, view a wide range of technology for bottle processing—and enjoy a biergarten!

Read MoreTwo Molders Investing in Medical Market

Currier Plastics and NPI/Medical invest in clean rooms; molding and blow molding machines; testing equipment and more.

Read MoreFocusing on People

In addition to numerous employees with two and three decades of experience, Iowa blow molder is building out its future staff via apprenticeships and area-school outreach.

Read More

.png;maxWidth=300;quality=90)