Materials Know How

Latest Materials Know How Articles

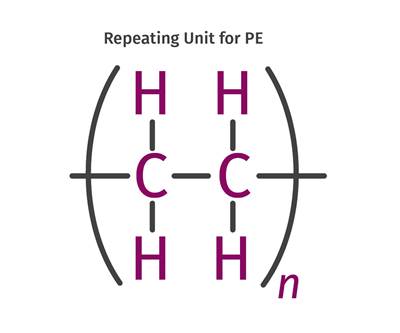

VIEW ALLFundamentals of Polyethylene – Part 5: Metallocenes

How the development of new catalysts—notably metallocenes—paved the way for the development of material grades never before possible.

Read MorePolyethylene Fundamentals – Part 4: Failed HDPE Case Study

Injection molders of small fuel tanks learned the hard way that a very small difference in density — 0.6% — could make a large difference in PE stress-crack resistance.

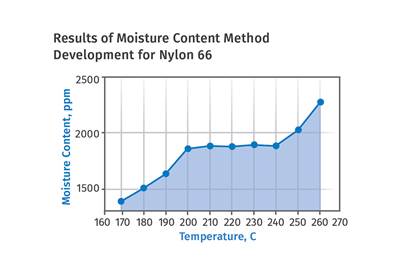

Read MoreUnraveling the Science and Myth Associated With Moisture Analysis — Part 2

Once you’ve selected the right moisture analyzer, the task of method development begins. Don’t skip this step or you’ll run into problems. Here’s what happened in my lab decades ago.

Read MoreFundamentals of Polyethylene – Part 3: Field Failures

Polyethylene parts can fail when an inappropriate density is selected. Let’s look at some examples and examine what happened and why.

Read MoreThe Fundamentals of Polyethylene – Part 2: Density and Molecular Weight

PE properties can be adjusted either by changing the molecular weight or by altering the density. While this increases the possible combinations of properties, it also requires that the specification for the material be precise.

Read MoreThe Fundamentals of Polyethylene – Part 1: The Basics

You would think we’d know all there is to know about a material that was commercialized 80 years ago. Not so for polyethylene. Let’s start by brushing up on the basics.

Read MoreLatest Materials Know How News And Updates

Featured Posts

Unraveling the Science and Myth Associated With Moisture Analysis— Part 1

The first task in moisture measurement is to purchase an instrument that is based on sound fundamentals. Then, before it goes into use, method development must be undertaken for all polymers that are going to be processed in the plant.

Read MoreThe Fantasy and Reality of Raw Material Shelf Life: Part 2

For the vast majority of thermoplastics, the stability of the materials can be stated in years, not months. But there are exceptions where shelf life can be a serious issue.

Read MoreThe Fantasy and Reality of Raw Material Shelf Life: Part 1

Is a two-year-old hygroscopic resin kept in its original packaging still useful? Let’s try to answer that question and clear up some misconceptions.

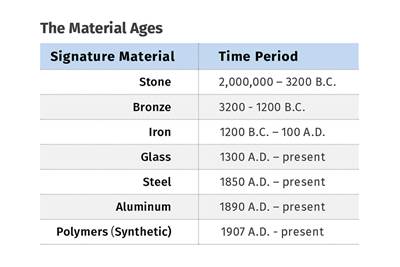

Read MoreImagine A World Where Polymers Were First

One reason for the disproportionate attention that plastics receive in the environmental conversation is that they are newcomers. Perhaps if we had been relying on them for thousands of years, we’d view them differently.

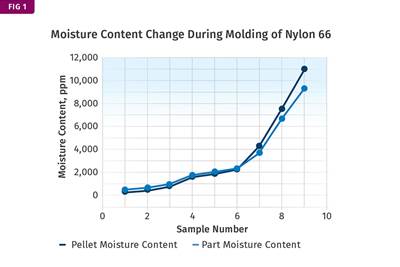

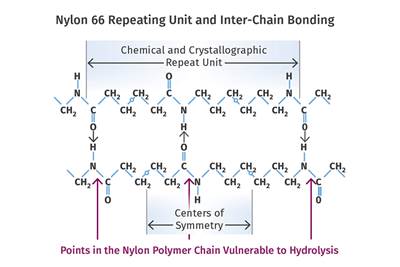

Read MoreWhat's the Allowable Moisture Content in Nylons? It Depends: Part 2

Operating within guidelines from material suppliers can produce levels of polymer degradation. Get around it with better control over either the temperature of the melt or the barrel residence time.

Read MoreWhat is the Allowable Moisture Content in Nylons? It Depends (Part 1)

A lot of the nylon that is processed is filled or reinforced, but the data sheets generally don’t account for this, making drying recommendations confusing. Here’s what you need to know.

Read More