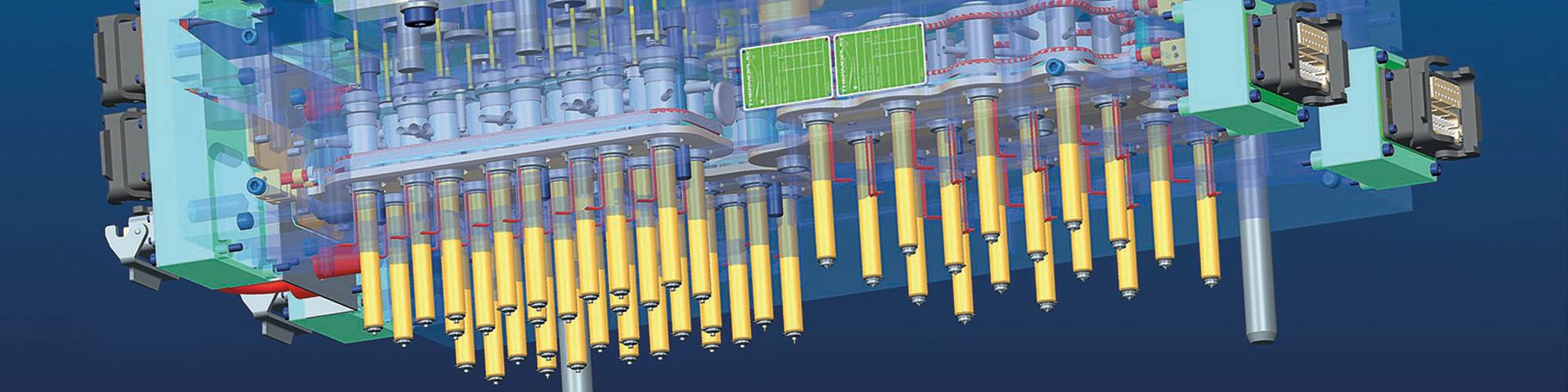

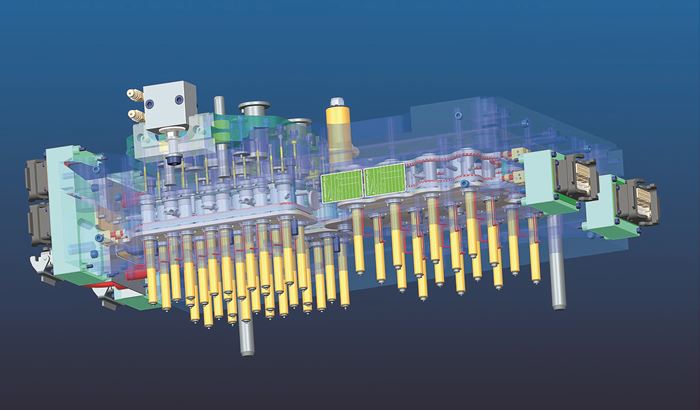

Hot-runner technology is increasingly being tailored to the very specific requirements of the and markets and applications it will be serving. That fine tuning is very much on display at NPE2018. For example, Milacron’s Mold-Masters is introducing additions and enhancements to its Fusion-Series G2 hot-runner line, which is geared towards large-part production where high-end quality is required. Delivered completely pre-assembled and pre-plumbed, the line features field-replaceable heater bands for quick maintenance and shot sizes that range from less than 15 g to more than 3500 g.

New at NPE2018 will be Mold-Masters F3000 and F8000 nozzles. The F3000 has a shot capacity of approximately 15 g and targets smaller under-hood parts, technical automotive components, and price-sensitive packaging and consumer goods. The F8000 increases the top shot capacity to 5000 g via runner diameters as large as 28 mm, with nozzle lengths that can exceed 1 meter. Target applications include bumper fascia, instrument panels, door panels and large white goods.

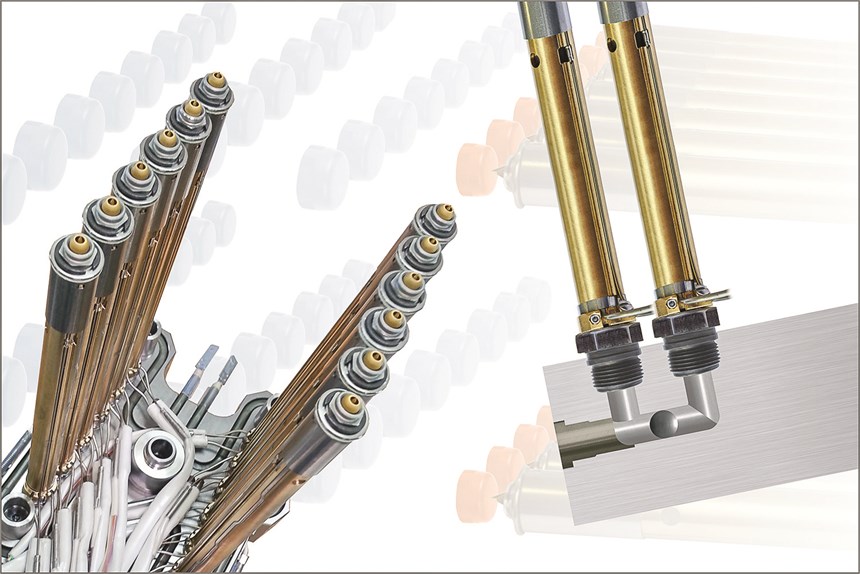

Mold-Masters is also introducing a second generation of its Melt-CUBE side-gating hot runner in Orlando. This system is promoted as having vestige control, low-pressure drop and precise cavity-to-cavity rheological balance. Melt-CUBE allows simultaneous direct side gating of up to eight cavities per CUBE for high-cavitation molds. Tips are located to gate and clamped by a single bolt in sets of two, greatly reducing assembly/disassembly times. Manifolds can be accessed from the parting line, and the system uses brazed heaters for a more precise thermal profile and superior reliability. Show attendees can experience assembly time reduction first hand with a hands-on display of the Melt-CUBE in booth.

Synventive will feature its synflow pin control, which can be added to any of the company’s activeGate systems through an external hookup so that molders do not have to commit to a flowcontrol technology for the life of the tool.

Synflow’s third generation has added the ability to stop the pin and hold it at any position mid-stroke. This allows for individual flow control of each nozzle to balance family molds or fill complex multi-gated geometries. Alternating opening profiles can be programmed, offering the ability to pre-fill cold runners or create differential packing within complex multi-gated parts.

NPE2018 will afford attendees four different opportunities to see HRSFlow’s FLEXflow electrically driven valve-gate system in action. In Wittmann Battenfeld’s booth, an automotive spoiler will be molded using a five-drop FLEXflow system. At Yizumi-HPM, a tool case will be molded using a three-drop FLEXflow system, in a process that also applies MuCell foaming and back injection. At KraussMaffei, a lightweight center-console armrest will be molded in cooperation with ProperTooling. Special features include a multicomponent (2 + 3) drop FLEXflow system enabling overmolding of TPV. A grained interior-trim component with decorative foils will be molded at Engel, using a five-drop FLEXflow system paired with in-mold graining and back injection of PP via MuCell foaming.

Günther Hot Runner Technology will feature a new two-phase hot-runner stepper motor that can individually control up to 16 valve pins. The DPE motors come in four versions differing by the number of channels: 4, 8, 12 and 16. All versions feature a central 7-in. LCD touchscreen display that shows all the all stepper channels’ current position in color.

Thermoplay is launching a newly expanded small-nozzle series featuring the F Ø11 mini valve-gate nozzle. Designed to meet the heightening requirements of special applications in cosmetic, medical and packaging markets, the new nozzle’s larger inner diameter ranges from 3.5 to 4 mm, allowing increased melt flow. The minimum pitch for the F Ø11 valve-gate version is 17 mm; that can be reduced to 13 mm with an open gate. F Ø11 valve-gate actuation can be pneumatic or hydraulic, as well as individually or plate actuated. The pin, available in a cylindrical or conical option, is designed to minimize the witness mark on the part. Also from Thermoplay, the DL-1B nozzle has an extended tip that is advantageous when the injection point is in critical locations that require a very small tip.

Incoe will expand its DF (Direct Flow) nozzle line at NPE2018. Originally launched at K 2016 with a 12-mm flow diam., the series now includes a slim DF 5 nozzle with 5-mm diam. and SBH (Slim Base Heater). Incoe notes that the “slim” design reduces the DF 5’s outer diameter by almost 25%, allowing nozzles with a large, 5-mm flow channel to be installed as close as 18 mm.

Incoe also has upgraded its GSCmini compact, low-cost, timer-based valve-gate sequencing controller. The new version can control either pneumatic or hydraulic valve actuation. Incoe recommends it for valve-gated applications that do not require sensors or linear transducer control, and for use in a tool room.

Männer is extending its Slimline nozzle range, launching a new product for valve gating in polyolefin applications with limited space. The small diameter—6.5 mm (0.256 in.)—of the Slimline caps and closure nozzle targets high-cavitation packaging applications.

Synventive’s new-generation valve-gate control has added the ability to stop the pin and hold it at any position mid-stroke.

Osco’s Jumbo valve-gate nozzle is designed for large shots and shear-sensitive resins. With what are said to be the largest feed channels ever used, Osco engineered this new, custom single-drop nozzle to deliver 28 lb of plastic for producing a container bin. The Jumbo eliminates the need for a multi-drop manifold system along with the temperature and valve-gate controllers. Significantly less time is needed in machining to accept the Jumbo nozzle compared with a four-drop manifold system. The Jumbo nozzle also requires less time to install, wire and plumb. Hasco’s Vario Shot nozzle series will be completed at NPE2018 with the addition of the Type 50 nozzle size. A new screw-in Vario Shot will also be introduced. Hasco says this design allows for ready-to-mount systems.

GETTING IN CONTROL

Sise is presenting its latest generation of multizone controllers. Sise says this new generation will offer four different soft starts, zone grouping, PTI function for thermocouple anomalies, Moldscan for real-time hot-runner diagnostics, and material-leak detection. Available in five sizes, the MV3, which will eventually be able to control up to 336 zones, has three available power cards for 2.5, 15 and 30 amps. MV3’s control uses a 10- or 15-in. touchscreen display. The system supports up to 11 languages and offers unlimited mold file memory. Sise notes that that MV3 can communicate with molding machines, supporting Industry 4.0, while monitoring and saving production temperatures.

New in temperature controllers is Incoe’s I-Series Pro. Based on the established I-Series controller, the new Pro model provides 12 to 144 zones (two zones per card) in a compact footprint. Gammaflux Controls Inc. will be exhibiting the G24 and LEC lines of controllers, with the LEC running in 2-, 6- and 12-zone configurations. The G24 will be shown as a standalone controller and with an integrated sequential valve-gate controller (SVGC). Athena Controls is working to expand the number of zones beyond the current 64 in its Bedros control system to 144 zones.

MOLD COMPONENTS/SUPPLIES

Milacron’s DME business unit is launching a new quality certification for its American standard mold base. In addition to these mold bases, the new DME Machined-4-Quality standard applies to the company’s American standard mold base A-Series, B-Series, AX, X and T-Series lines.

Meusburger’s new E 3064 guide for inclined pins reportedly provides optimal surface contact with the inclined pin, resulting in a high force absorption. Meusburger notes that the machining of the pocket in the slide is possible without inclining, and that the slide stroke can be customized by adjusting the guide’s position.

Meusburger’s new E 1307 fine-centering unit is flat and requires minimal installation space. The DLC-coated centering elements are available with or without fixing holes, which enable maximum flexibility in design and reduce wear. Meusburger designed this centering element to be as small as possible for exact centering of individual inserts. The product features a compact design and defined installation positions, which prevent incorrect mounting of centering parts. Ensuring minimal wear, the unit is suited for use in clean rooms. The centering parts’ large chamfer on the contact surface enables corner radii for better hardening results on the insert, while also facilitating assembly.

In mold-base technologies, Hasco will highlight locating guide bushings with a circlip groove and new, individually printable nameplates for custom identification of molds. CUMSA will launch two vacuum devices to remove trapped air from the mold cavity. The Double Action Vacuumjet (VB) and the Smart Vacuumjet (SV) are based on the Venturi principle, so that only 6 bar (90 psi) of compressed air are needed to pull out gases at rates up to 60 liters/min. CUMSA adds porous inserts and/or laminar vents in critical areas of the mold, including at end of fill, to remove gases during injection and create less resistance to melt flow. The VB and VS can now also blow off the vents with compressed air after every cycle through the same vacuum channel.

The Smart Vacuumjet (SV) senses and displays the level of vacuum achieved in the cavity. If the desired vacuum cannot be achieved after 5 sec, but levels exceed -200 mbar, the SV will close the valve and start injection, indicating the maximum achieved vacuum with red numbers (instead of green) in the display. If, however, after that time vacuum does not reach the minimum threshold, the unit will not send the signal to start injection to avoid production of low-quality parts, with the display indicating the cause of the producton stop.

The patent-pending Linked-Valve system of linkages from Plastixs allows a single lever to simultaneously operate mold-cooling supply and return lines. The product is currently available for use on both 1- and 1.5-in. Smartflow aluminum manifolds and Plastixs 1- and 1.5-in. compact stainless-steel manifolds.

DMS’s NPE2018 display includes the Almo worm-gear device that enables inserts to be tightened and released inside the mold cavity without dismantling the mold. DMS will also show Bolex P ball-guided ejector bushings. Here, the balls do not run aligned but at a slight angle, enlarging the contact area and enabling greater load capacity. Also, the company’s BZ hydraulic locking cylinders with robust cam-finger design are said to withstand heavy loads in a compact package for molds with side actions, slides or core pulls.

ALBA Enterprises will feature its line of ejector couplers that automatically connect and disconnect on every cycle through the standard motions of the machine. This eliminates the need for specialized rods for each mold, while guaranteeing full return of the ejector plate. During a mold change, processors need only to move the machine knockout to the full back position. At that point, they are free from the mold and clear for removal of the tool. Since there is no manual connection or disconnection required, ALBA couplers are especially suited for use in machines that have little access to the ejector plate. They also allow for center ejection to be tied in.

SelfLube will showcase its trunnion lifter slides, which come in inch and metric sizes and are available with or without self-lubricating graphite.

MOLDMAKING & MAINTENANCE PRODUCTS

Uddeholm will showcase Uddeholm Mirrax ESR at NPE2018. The premium-grade stainless steel is especially suited for molding applications, according to the company. Mirrax ESR is described as a high-polish stainless tool steel with a combination of toughness, corrosion resistance, and uniform hardness across large cross sections. The company will also launch Corrax AM powder, a specially designed metal powder for additive manufacturing in plastics tooling applications.

Bales Metal Surface Solutions will highlight a number of coatings and finishes to protect metals from wear, abrasion and corrosion. Its Diamond E.N. product reportedly provides the uniform corrosion resistance of electroless nickel with the added toughness of diamond particles for a hardness of 57 Rockwell C.

MOLD MONITORING/TRACKING

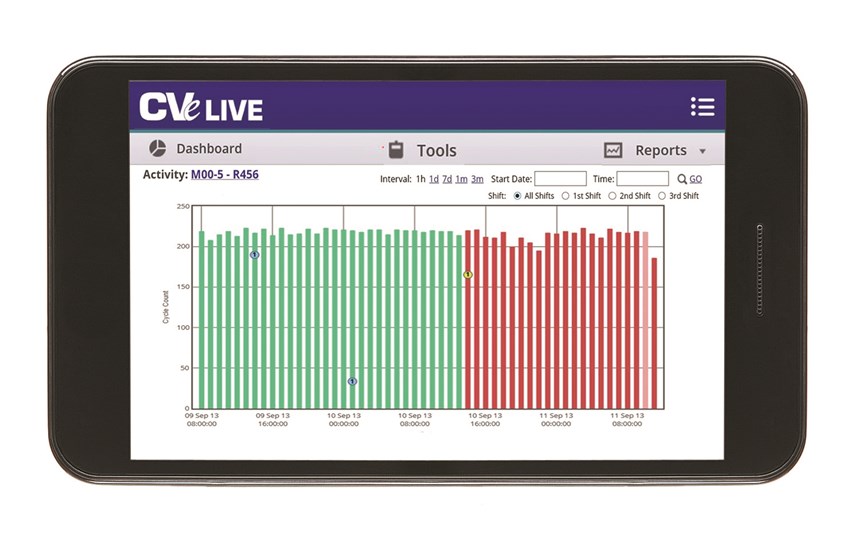

Progressive Components will introduce a monitoring and transmission platform that it says will advance the way the plastics industry monitors and maintains its tools. Progressive is pairing its tool-mounted CVe Monitor electronic mold-monitoring device to its CVe Live wireless device that relays data to the cloud-based CVe Live website.

New CVe Live features to be launched at NPE2018 include a Press Management Module that allows for scheduling, tracking, monitoring, and filing of all preventive-maintenance actions. An expanded electronic filing cabinet with the ability to add non-CVe assets to the database and store related documents has been added.

Related Content

50 Years...600 Issues...and Still Counting

Matt Naitove marks his first half-century in plastics reporting, with a few of his favorite headlines.

Read MoreTake Time to Save Time: Five Steps in Mold Design to Reduce Back-End Troubleshooting

Westminster Tool shares how the one week it typically takes to perform these five steps in the design phase can save three weeks or more in an overall tool build.

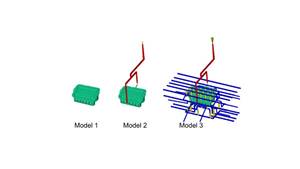

Read MoreHow to Achieve Simulation Success, Part 1: Model Accuracy and Mesh Decisions

Molding simulation software is a powerful tool, but what you get out of it depends very much on your initial inputs. Follow these tips to create the most successful simulation possible.

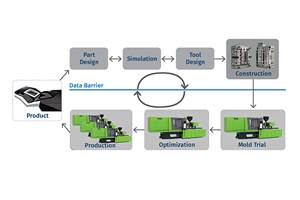

Read MoreInjection Molding Simulation Meets the Real World

Direct data interface between molding simulation and the injection machine links the computer model to the real-world process. This can improve results from product and mold design through ongoing production. A case study demonstrates these benefits for automotive components in a family mold.

Read MoreRead Next

Advanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read More