Moving Die Parts Change Profile Shapes 'On the Fly'

Change one tubing lumen into two, or two lumens into three, or even split one tube into two in a “Y” shape: These are some of the dramatic alterations that can be made “on the fly” with a novel articulated die concept available for license from Specialty Silicone Fabricators, a medical tubing maker in Paso Robles, Calif.

Change one tubing lumen into two, or two lumens into three, or even split one tube into two in a “Y” shape: These are some of the dramatic alterations that can be made “on the fly” with a novel articulated die concept available for license from Specialty Silicone Fabricators, a medical tubing maker in Paso Robles, Calif. It builds dies with moving components capable of extruding profiles that transform continuously from one shape to another.

Specialty Silicone’s shape-shifting Geotrans (geometric transition) die technology has been used so far only for the company’s silicone rubber tubing, but it can be licensed for non-medical thermoplastic applications.

Moving die parts

Specialty Silicone has patented a number of dies with moving parts:

- Continuous “Y”-shaped lumen has one lumen that splits into two or three inside a continuous tube.

- Lumens can start and stop, previously accomplished only by welding plugs in a secondary operation. This tooling (U.S. Patent 6,394,141, May ’02) raises and lowers tines in the die mandrel.

- Three moving die sections make a one-piece, “Y”-shaped tube (U.S. Patent 5,945,052, Aug. ’99) with one inlet tube that transforms seamlessly into two. Previously such tubes could be made only by welding individual tubes onto a molded “Y” connector, with the inherent risk that the welds could come apart. Specialty Silicone has even built dies to transform one tube into three.

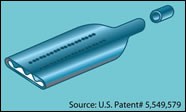

- A one-piece surgical drain changes shape from a small round tube with 3/16-in. OD into a wide, flat hollow profile 10 x 4 mm and then back again (U.S. Patent 5,549. 579, Aug. ’96). The single lumen transforms from round to a flat oval with ribs on one side that keep the flat lumen from collapsing. The mandrel is round in front, sloping smoothly into a flat oval with lengthwise ridges on one side. As the mandrel oscillates back and forth in the die, it changes the lumen from round to ribbed oval. At the same time, die plates outside of the profile move in and out to reshape the outside from round to flat and back, keeping nearly constant wall thickness.

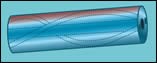

- Specialty Silicone’s latest tooling (patent pending) creates spirals inside a profile. For example, multiple lumens can loop or twist around each other inside a solid tube to prevent kinking. Spirals are made with a linear sequence of two or more “tortuous conduits,” threaded to give different cross-sections.

A solid panel can also be molded in the die wall in the form of a spiral baffle to provide static mixing or turbulent flow. “The lumen spins, stops, then spins in the other direction. The spirals go one inch in one direction, then reverse and spiral one inch in the other direction,” explains v.p. of R&D Charles Schryver, co-inventor of the dies. “Then the wall between the two lumens stops, and the two lumens flow together.”

- Specialty Silicone’s first patent simply creates tubing with a constant ID and variable OD (Patent 5,511,965 April ’96). This can produce catheter tubes with stiff, thick sections and thin, flexible sections. Variable OD is made by moving a ring forward and back against the die plate to alter the gap between the die opening and mandrel.

Good for thermoplastics?

An unanswered question is whether Specialty Silicone’s moving-die technologies will work with thermoplastics. Commercial designers and makers of profile dies for both silicones and thermoplastics give a qualified “yes.” Shear and viscosity requirements are similar, they say, except that thermoplastic extrusion provides continuous flow, while silicone extrusion can start and stop. Silicone dies need cooling channels, and thermoplastic dies need heating channels. Neither can be used in moving die parts.

“My gut feeling is that it could be done,” says James Rathert, general manager at die maker Genca. “But it would be complex.” He notes that moving parts could create pockets where thermoplastics could burn, while silicone doesn’t degrade in the die.

Related Content

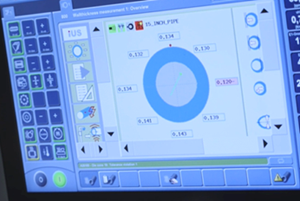

Crosshead Die Features Single-Point Concentricity Adjustment

One adjustment bolt controls 360° of adjustment.

Read MoreFully Automated Extrusion Process Enables Use of Composites for Manufacturing Pressure Tanks

Amtrol was looking for a more cost-effective means to produce thin-wall liners for a new line of pressure tanks. With the help of a team of suppliers, they built one of the world’s most sophisticated extrusion lines.

Read MoreOnline X-Ray Inspection Boosts Extrusion Quality

Höhle uses Sikora’s x-ray measuring systems for inline quality control of extruded microducts.

Read MoreTeel Straps on Yellow Belt to Cut Scrap on Big Cores

Investments in a lean, continuous process pay off for this Wisconsin processor.

Read MoreRead Next

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More (2).jpg;maxWidth=970;quality=90)