Search Results

Showing 11 – 20 of 32 resultsCooling is crucial to the molding process yet frequently overlooked. Here are some insights to consider.

An overlooked factor in injection molding has outsize influence on the process and part quality.

Some creative thinking with conventional technology, like small cooling lines and bubblers, can generate big improvements in cooling and cycle times.

Lifters can cause tool maintenance, repair, and processing issues if not designed properly. Here we begin a series on how to avoid all this.

Flash, venting, cooling, gating, or sticking problems? Better to fix the tool than distort your process.

This is the final part of a series on tooling in the press. This column will cover repairs that can be accomplished in the press.

Pay attention to water leaks and rust, proper grease selection, vent buildup, and checks for wear.

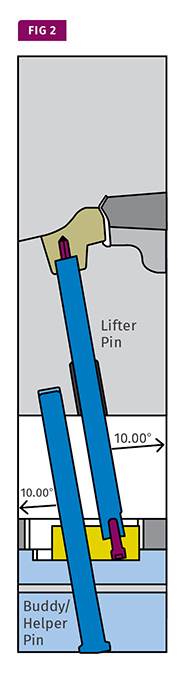

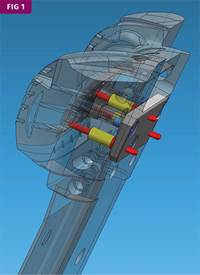

This installment delves into more detail on some variables of design and fitting/timing of the lifters, which can cause issues or failures during molding.

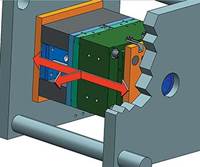

Attention to design of cooling, ejection, and slides can save downtime and maintenance headaches.

Principles to follow in venting bosses, ribs, pins, cores, slides, and lifters.