Injection Know How

Rethinking Regrind

Regrind and recycled material are often requisite in projects these days, but for many molders, the “R” word triggers painful memories.

Read MoreInjection Molding: Focus on these Seven Areas to Set a Preventive Maintenance Schedule

Performing fundamental maintenance inspections frequently assures press longevity and process stability. Here’s a checklist to help you stay on top of seven key systems.

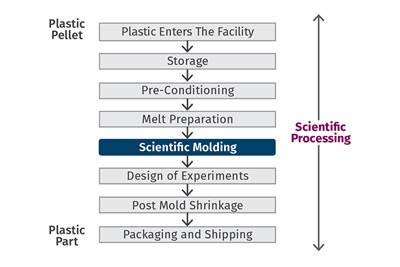

Read MoreA Systematic Approach to Process Development

The path to a no-baby-sitting injection molding process is paved with data and can be found by following certain steps.

Read MoreSecrets of Quick Part-to-Part Changeovers

Part-to-part changeovers can be fast only with proper advance planning. Here’s what you need to know to convert from sluggish to swift in job changes.

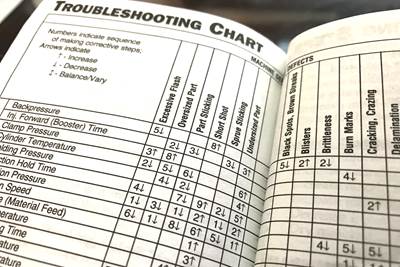

Read MoreApply the Power of a Troubleshooting Checklist to Your Process

Pocket guides provide processors an injection molding “crib sheet,” but in a process with thousands of interactions, applying if-this/then-that logic can’t always get you to a problem’s root cause.

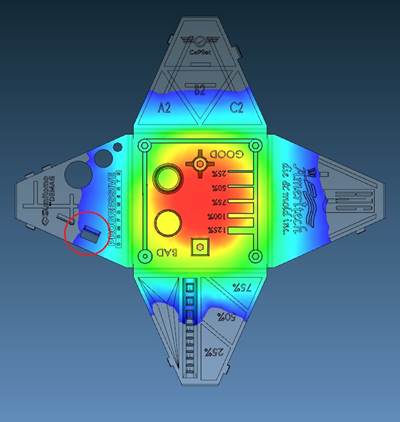

Read MoreThe Difference Between Knit and Meld Lines--and Why It Matters

In many part designs, flow fronts will inevitably be split, but how and where they come back together is hugely important to the molded part’s finished strength.

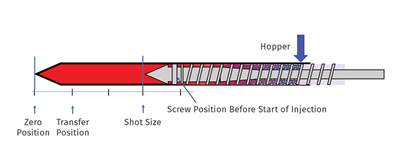

Read MoreConsider the Cushion When Seeking Shot-to-Shot Consistency

Creating and maintaining a consistent cushion is a key step in achieving shot-to-shot consistency. Learn what cushion is and how it affects part quality.

Read MoreThree Key Decisions for an Optimal Ejection System

When determining the best ejection option for a tool, molders must consider the ejector’s surface area, location and style.

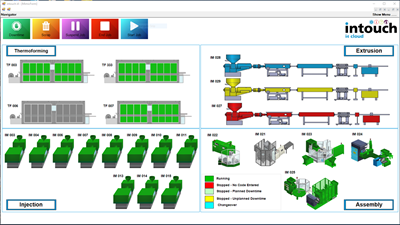

Read MoreProcess Monitoring or Production Monitoring—Why Not Both?

Molders looking to both monitor an injection molding process effectively and manage production can definitely do both with tools available today, but the question is how best to tackle these twin challenges.

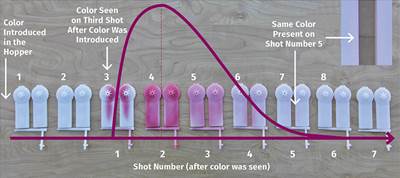

Read MoreThe Importance of Gauging Residence-Time Distribution—Part 2

Each molecule in the molded product can have a different residence time. This variance is reflected in the Residence-Time Distribution, which you can learn how to determine below.

Read More

.png;maxWidth=300;quality=90)