Injection Molding

Annual RJG Global Mold Smart Award is Now Open for Applications

Potential 2024 award candidates are dedicated to transforming their injection molding company using RJG technology or service solutions. Applications are due by Dec. 31, 2023.

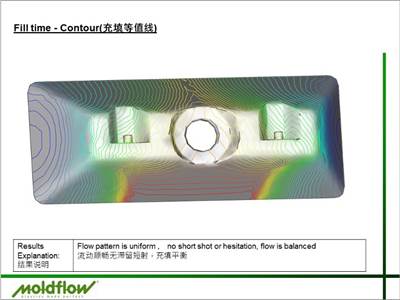

Read MoreHow to Achieve Simulation Success in Molding, Part 3: Inputs, Reports and the Analyst

Ultimately the success of this virtual, digital software falls to the real-world, analog humans requesting and completing the analysis.

Read MoreMicrocellular Foaming Paired With Specialized Screw, Process Control Program

KraussMaffei will apply its APCplus dynamic process control technology and an optimized screw with the MuCell process in Friedrichshafen.

Read MoreTessy Plastics Names New President

Owner Roland Beck will transition from president to CEO as longtime Tessy employee, Stafford Frearson, takes the reins of the global injection molder and contract manufacturer.

Read MoreMolder Repairs Platen Holes with Threaded Inserts

Automotive molder ITW Deltar Fasteners found new life for the battered bolt holes on its machine platens with a solution that’s designed to last.

Read MoreManifold Blocks for Flexible Cooling Circuits

Hasco’s Z920/... manifold blocks create a centralized inflow/outflow location that enables the use of shorter hoses in mold heating/cooling systems.

Read MoreFakuma 2023: More Details on New Machine Line

Wittmann Battenfeld has released more details on the new EcoPower B8X debuting at Fakuma (October 17-21; Friedrichshafen, Germany), which it previously announced.

Read MoreKraussMaffei and NIAR Propel Injection Molded Thermoplastic Composites

The maker of plastics processing equipment has placed a machine and an injection molding expert in NIAR’s ATLAS lab in Wichita, Kansas, to help molding, composites and aerospace take off.

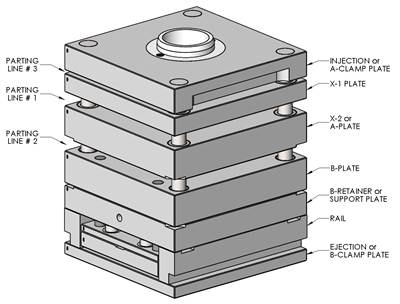

Read MoreHow to Design Three-Plate Molds, Part 1

There are many things to consider, and paying attention to the details can help avoid machine downtime and higher maintenance costs, and keep the customer happy.

Read MoreUsing Data to Pinpoint Cosmetic Defect Causes in Injection Molded Parts

Taking a step back and identifying the root cause of a cosmetic flaw can help molders focus on what corrective actions need to be taken.

Read More

(2).jpg;maxWidth=300;quality=90)