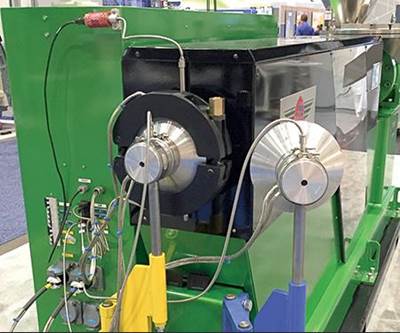

Single-Screw Compounding

EXTRUSION AND COMPOUNDING NPE: Flexibility, Speed and Quality

Extrusion processors need more—of everything—to compete. And suppliers responded in force in Orlando.

Read MoreItalian Equipment Makers Aim For U.S. Expansion

Expansion plans by some Italian plastics equipment manufacturers are focused on North America

Read MoreAre You a ‘World-Class’ Processor?

Participate in Plastics Technology’s industry-wide benchmarking survey and you might find out.

Read MoreEXTRUSION AND COMPOUNDING AT NPE: The Word Is ‘More’

As in speed, power, quality, flexibility, layers, and efficiency. Those are the trends across all extrusion processes.

Read MoreTPEI Adds Laser Alignment to Service Offerings

Proper alignment of equipment should increase its overall lifespan.

Read MoreThe Paradox of Proportioning

Continuous proportioning typically involves a group of gravimetric feeders operating under some form of higher level coordinating control. One would think the result should be a perfectly formulated composite stream. But the devil is in the details.

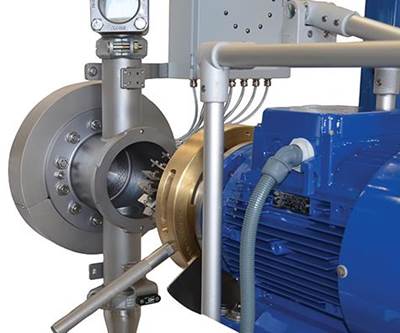

Read MoreSolving Common Problems in Underwater Pelletizing

Pellet quality and consistency are critical to any compounding operation. But in underwater pelletizing, a variety of issues can stand in the way. Here’s how to fix them.

Read MoreExtrusion/Compounding at K 2013: Having It All

Extrusion processors no longer need to chose among speed, quality, and flexibility, based on exhibits at K 2013.

Read MoreK 2013 Preview: Extrusion, Compounding, Recycling

Across all extrusion technologies, expect to see new standards in speed, quality, flexibility, and efficiency in both energy and material usage.

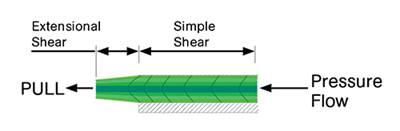

Read MoreNew Frontier for Single Screw R&D: Mixing & Melting by Extensional Shear

Extensional shear generally has been associated only with twin-screw extruders. However, I am now convinced it can be done with a single moving force (screw) by changing the geometry of the flow field perpendicular to the direction of flow.

Read More

(2).jpg;maxWidth=300;quality=90)