Micromolding

Latest Micromolding Articles

VIEW ALLIMM Cells Display Communications, Energy Measurement and Energy Recovery

NPE2024: Wittmann will feature five injection molding machines incorporating its range of robotics and auxiliaries, with all products employing industry 4.0 communications, energy measurement and a brand-new red color.

Read MoreMidtonnage Hybrid Range With Compact Footprint Launches

NPE2024: Milacron has the global launch of its new M-Series injection molding machine line featuring a large clamp stroke as standard in a line of midtonnage, compact-footprint machines.

Read MoreArterex Acquires Micromold

The medical device contract manufacturing company with eight facilities globally has purchased the Riverside, California-based micromolder.

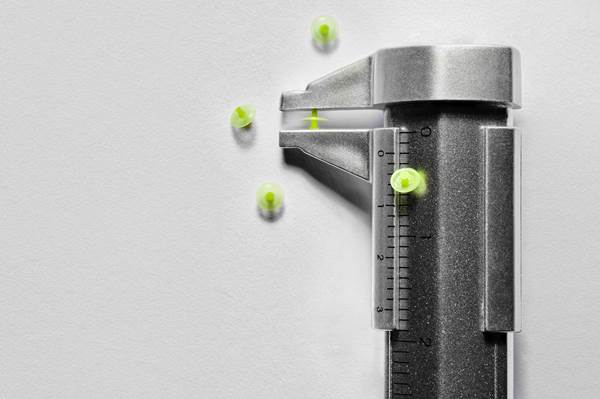

Read MoreNew Machine Range Features Adjustable Clamp for Micromolding

The Boy XS E, successor to the XS series, features servodriven pump drives and different clamp configurations, as well as a special mold holder for optional micromolding operation.

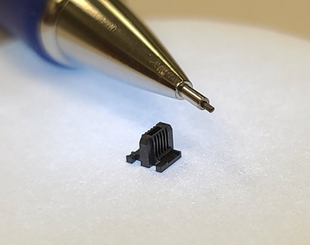

Read MoreInnovative Micro-Molding From Minnesota Machine Shop

Machine shops are natural inventors, but not necessarily suited to supporting and marketing a product. This Minnesota shop with an invention related to micromolding will share it through licensing.

Read MoreMatrix Tool: Welcome to the Family

In its 50th year, Matrix Tool applies moldmaking and injection molding expertise, plus a long family heritage, to high-precision jobs that many would deem impossible.

Read MoreLatest Micromolding News And Updates

X2F and Covestro Collaborate on Innovative In-Mold Electronics for Automotive Lighting

Thermally conductive PC heat-sinks produced with X2F controlled viscosity molding.

Read MoreFakuma: Wittmann Battenfeld to Launch Machine Line at Friedrichshafen Fair

In addition to introducing its new SmartPlus line of servo-hydraulic injection molding machines, Wittmann Battenfeld will feature multiple machines at its booth and stream video of other cells from its labs.

Read MoreWestfall Technik Opens Medical Molding Facility

The one-time MGS plant outside Chicago in Antioch, Ill. features multiple cleanrooms and will become a micromolding center of excellence.

Read MoreFreudenberg Medical Adds Six Machines

The Arburg, Wittmann Battenfeld and Toyo machines installed in Baldwin Park, Calif. support component production for in-vitro diagnostic test kits.

Read MoreMTD Micro Molding Completes Expansion

The Massachusetts based micro molder and moldmaker has added 11,700-ft2 to its facility, effectively doubling its clean room manufacturing space.

Read MoreFakuma Show Goes On (Digitally) for Wittmann Battenfeld

Self-contained inline scrap integration; medical, LSR, and packaging Cells; an MES Upgrade and more to be introduced virtually.

Read MoreFeatured Posts

Matrix Tool Wins Inaugural Hot Shots Competition

The Pennsylvania-based injection molder and moldmaker applied its tooling know how and Sodick injection technology to take home both Hot Shots prizes.

Read MoreK 2019 Preview: Injection Molding Goes for the ‘Green’

‘Circular Economy’ joins Industry 4.0 as common themes of injection molding exhibits in Düsseldorf.

Read MoreMicromolding Puts on a Pretty Face

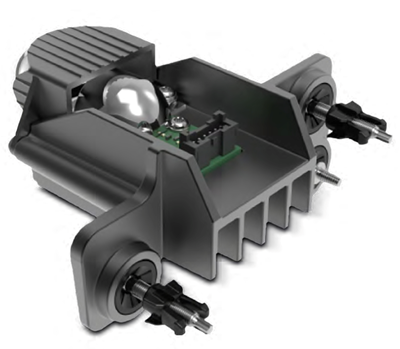

A leading manufacturer of cosmetics packaging bought a dozen Wittmann Battenfeld MicroPower injection systems to mold micro components of dosing pumps for beauty products.

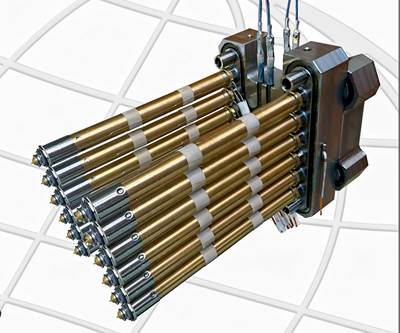

Read MorePlentiful News in Hot Runners at Fakuma Show

More compact hot runners, even for large parts; smarter controls; unusual nozzle designs; remote mold monitoring; and a new source of LSR cold-runners.

Read MoreSmall Machines with Big Technology Portfolio

Boy Machines is demonstrating more technology “bang for the buck.”

Read MoreNPE2018 New Technology Focus: Micromolding is Big

Micromolding is a growing force in medical, electronics and micromechanical parts.

Read More