Articles

Avoiding Common Cosmetic Defects in Molded Parts

Identify familiar flaws and then work to eliminate them with these mold and part design tips, and process considerations.

Read MoreThe Fantasy and Reality of Raw Material Shelf Life: Part 1

Is a two-year-old hygroscopic resin kept in its original packaging still useful? Let’s try to answer that question and clear up some misconceptions.

Read MoreFreeform Injection Molding Eases the Path to Medical Device Product Testing

A development and manufacturing service provider is using dissolvable molds to build injection molded silicone prototypes.

Read MoreSix Years in the Waiting, PLASTICS Igniting a ‘Spark’ at NPE

New features of NPE2024 aim to “bring the whole plastics ecosystem together to innovate, collaborate and share findings.”

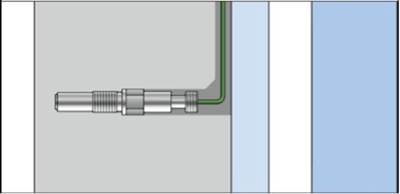

Read MoreMeasuring Strain — Not Pressure — for Precision Injection Molding

A contact-free sensor measures the strain the melt imparts on the mold wall and promises precise, reproducible measurements with lower maintenance, longer service life and blemish-free parts.

Read MoreDaimler, OMIC Evaluate Wire-Fed DED for Moldmaking

3D printing a core and cavity on machine from Gefertec, followed by machining, allowed for a complete mold tool to be produced in three days.

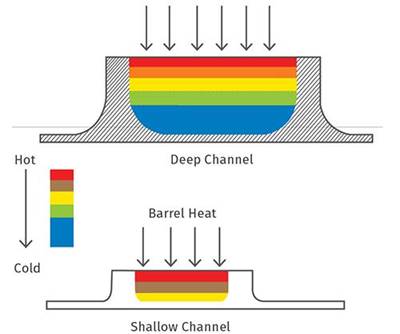

Read MoreThe Importance of Barrel Heat and Melt Temperature

Barrel temperature may impact melting in the case of very small extruders running very slowly. Otherwise, melting is mainly the result of shear heating of the polymer.

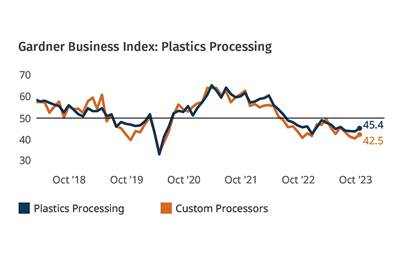

Read MoreContraction in Processing Slows in October

The Gardner Business Index for plastics processing activity jumped a bit in October, though it still contracted as it has since July 2022.

Read MorePrices Flat for PE, PVC, Up for PP and PS, Down for PET

A mixed bag, though prices likely to be down if not flat for all this month.

Read MoreSustainability, Innovation Intertwined at TC Transcontinental Packaging

Just 10 years in the plastics packaging business, TC Transcontinental has invested heavily to help its brand owner and retail customers meet their sustainability goals.

Read MoreChoosing the Right Projects to Automate

What are the strategies and upfront work that go into identifying production problems that could benefit from an automation solution?

Read MoreMedical Molder, Moldmaker Embraces Continuous Improvement

True to the adjective in its name, Dynamic Group has been characterized by constant change, activity and progress over its nearly five decades as a medical molder and moldmaker.

Watch