Know-How

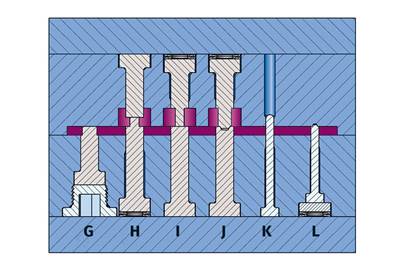

How to Form a Hole with a Core Pin: Part 2

Prevent wear, flash, and mold damage with these design methods.

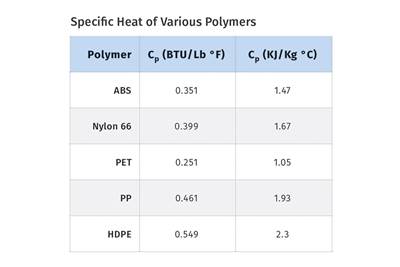

Read MoreThe Importance of Specific Heat in Screw and Extruder Design

If you ever have to size an extruder drive, knowing the specific heat of the polymer can help you to determine the capability of your equipment.

Read MoreInjection Molding: Focus on these Seven Areas to Set a Preventive Maintenance Schedule

Performing fundamental maintenance inspections frequently assures press longevity and process stability. Here’s a checklist to help you stay on top of seven key systems.

Read MoreHow to Form a Hole with a Core Pin: Part 1

Prevent wear, flash, and mold damage with these design tips.

Read MoreTracing the History of Polymeric Materials: Polycarbonate

How polycarbonate came about, virtually simultaneously, through the efforts of two industry giants.

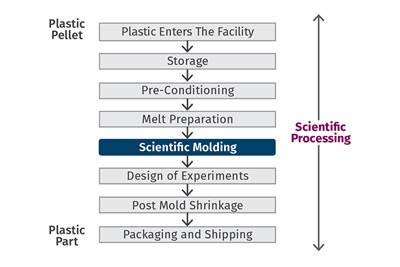

Read MoreA Systematic Approach to Process Development

The path to a no-baby-sitting injection molding process is paved with data and can be found by following certain steps.

Read More80 Questions Moldmakers Should Ask Themselves … and Their Customers

If you’re a molder or brand owner/OEM, be ready to supply the answers before the program is launched.

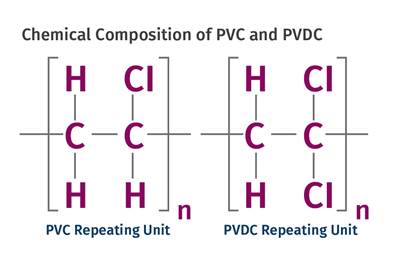

Read MoreTracing the History of Polymeric Materials: PVC & PVDC

How a class of materials based on chlorine chemistry became part of the landscape.

Read MoreSecrets of Quick Part-to-Part Changeovers

Part-to-part changeovers can be fast only with proper advance planning. Here’s what you need to know to convert from sluggish to swift in job changes.

Read More