Injection Know How

Latest Injection Know How Articles

VIEW ALLUnderstanding the Effect of Pressure Losses on Injection Molded Parts

The compressibility of plastics as a class of materials means the pressure punched into the machine control and the pressure the melt experiences at the end of fill within the mold will be very different. What does this difference mean for process consistency and part quality?

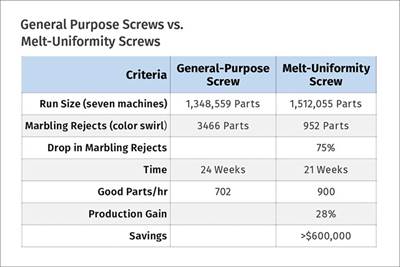

Read MoreImprove Production Rates Via Screw Design — Barrier vs. General Purpose vs. Melt Uniformity

I’m looking for a few good molders to help trial a new screw design, and share data and results for a future article to prove the benefits of a melt uniformity screw.

Read MoreThe Experience Curve and Well-Trained Process Technicians

Pairing external big picture training with internal job-specific instruction can help your process technicians meet quality expectations as well as production targets.

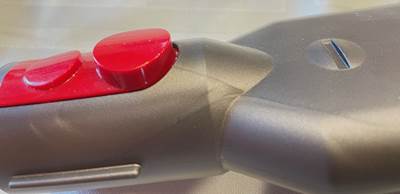

Read MoreAvoiding Common Cosmetic Defects in Molded Parts

Identify familiar flaws and then work to eliminate them with these mold and part design tips, and process considerations.

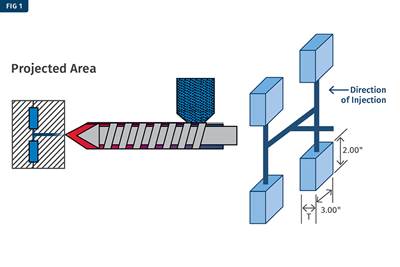

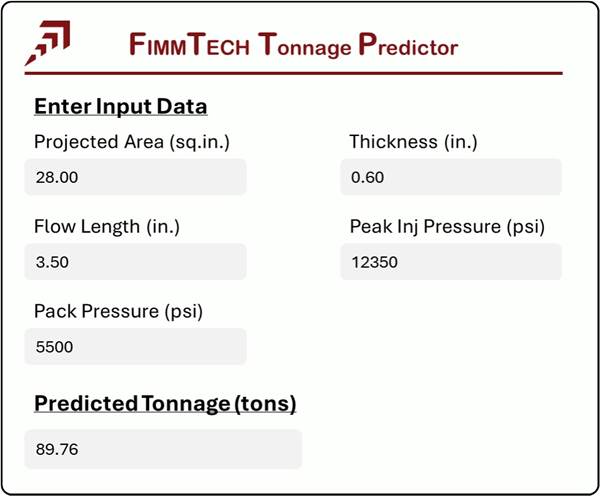

Read MoreIs There a More Accurate Means to Calculate Tonnage?

Molders have long used the projected area of the parts and runner to guesstimate how much tonnage is required to mold a part without flash, but there’s a more precise methodology.

Read MoreUsing Data to Pinpoint Cosmetic Defect Causes in Injection Molded Parts

Taking a step back and identifying the root cause of a cosmetic flaw can help molders focus on what corrective actions need to be taken.

Read MoreLatest Injection Know How News And Updates

Featured Posts

The Cost of High Employee Turnover in Injection Molding: Why Retention Matters

Starting in molding in 1993 and clocking in for nearly every job on the floor over the intervening decades, I’ve seen all sides of the hiring, training and retention process in the industry. Here are my thoughts on how to keep your most important asset — your people.

Read MoreThe Importance of Hot Nozzle-Tip Mating Against a Cold Sprue Bushing

Done improperly, the result is a cold slug in the nozzle/sprue and a production stop. But there is a better way.

Read MoreTime to Swap Out Those General-Purpose Injection Nozzle Tips

Still the standard in the industry, GP nozzle tips can cause a myriad of problems for molders. There are alternatives out there that should be examined.

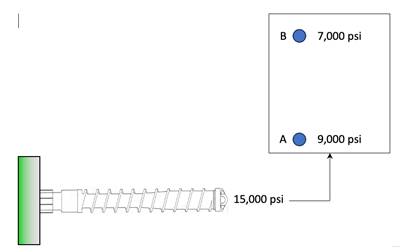

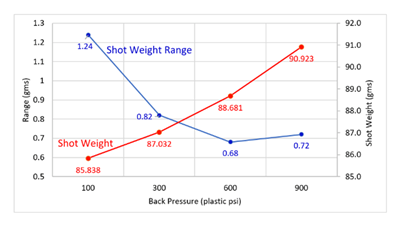

Read MoreHow Backpressure Optimization Affects Melt Preparation

Backpressure is often the least understood of the settings in an injection molding process, even though it can play a significant role in the final quality of the part. Let’s start with understanding what backpressure is and then learn how to optimize it for a given mold.

Read MoreHow Important is Minimizing Residence Time in Injection Molding?

Does a focus on the concept of “minimum residence time” distract attention from areas of injection molding that have more of a direct impact on melt quality?

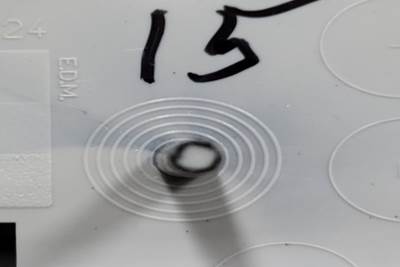

Read MoreUnderstanding Flow Fronts and Defects

Flow-front behavior and corrections are key to solving many common molding problems —what is your process’s flow trying to tell you about your part?

Read More